Installing Mini Cooper (R50/53)

Camber Plates

One of the

shortcomings of our BMW Mini Cooper is the lack of negative camber up front AND

weak strut towers which sometimes leads to mushrooming/deformation (more

details on that found HERE

). Hotchkis

Camber Plates address both issues. I sourced mine from Way’s online store, Way Motor Works, after getting his

feedback on pros/cons of the available types- he runs the Hotchkis camber

plates on his track car.

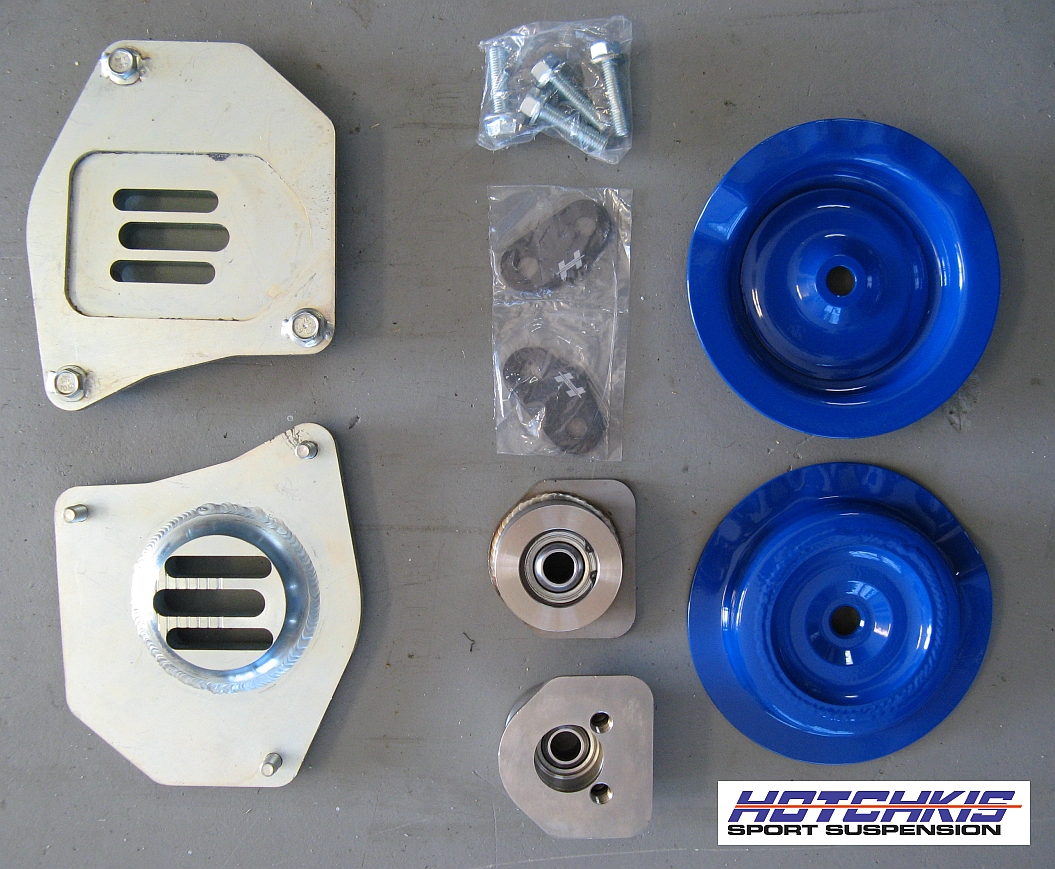

The

spherical bearings on the Hotchkis plates are replaceable and the spring hats

can be replaced if changing to a different spring type, if I change to

coilovers in the future I will just need new spring hats (blue items in below

pic).

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK. This guide is meant to be a supplement to the

Hotchkis Installation Instructions HERE

and not a replacement.

Looking at

how thick the plates are it is easy to see how they will reinforce the weak

strut tower sheet metal:

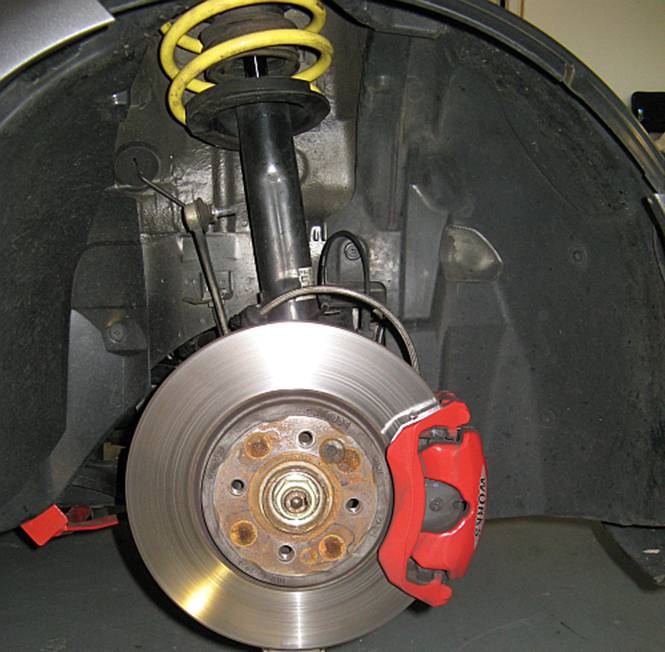

First step

is to jack up the front side that you will be working on (using jack stands of

course) and after placing jack stands under the car, removing the wheel/tire:

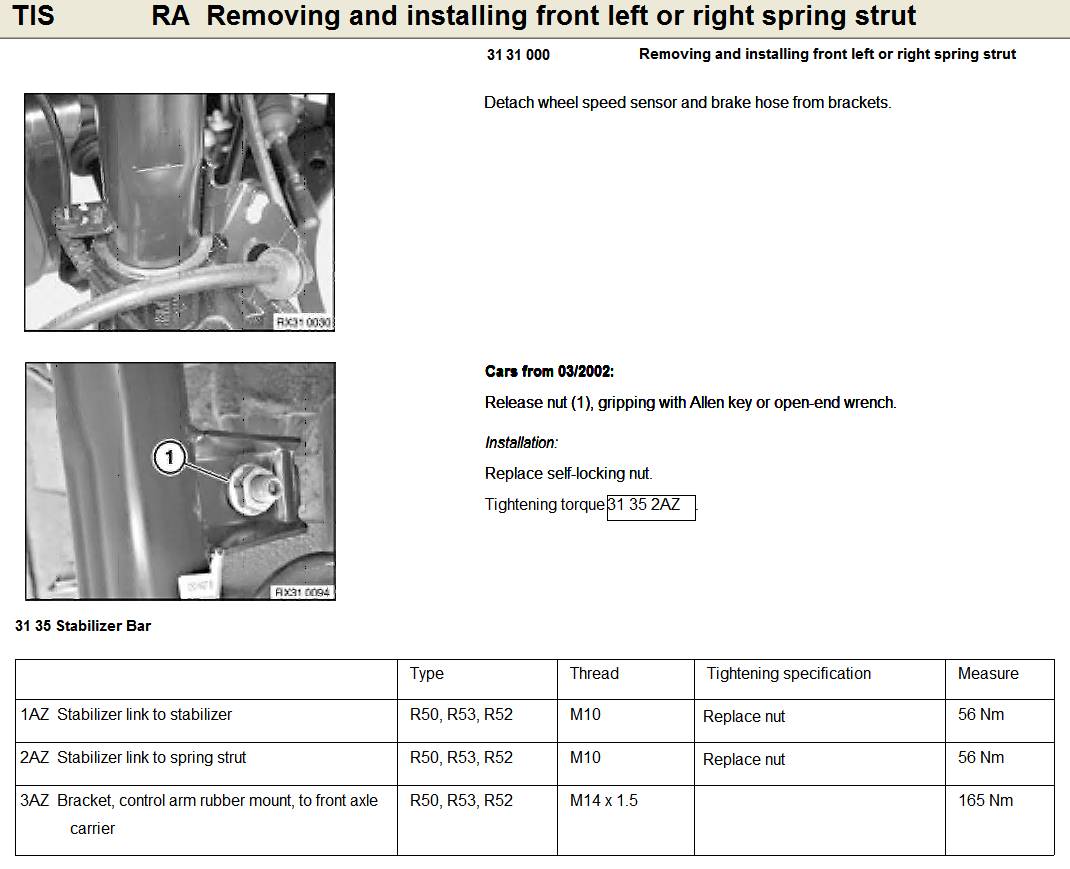

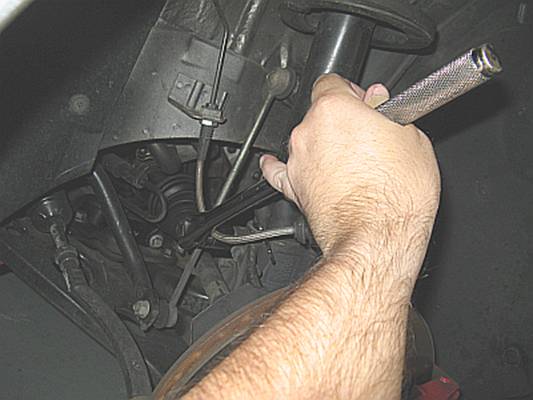

Remove the

brake line and brake sensor wire from the strut retainers carefully:

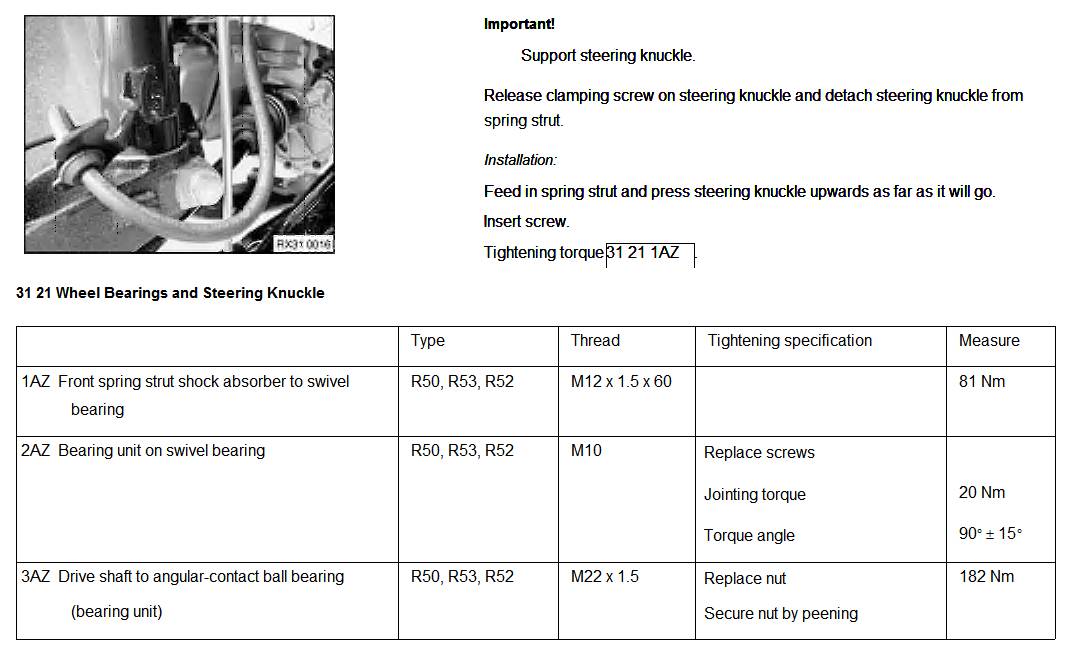

Remove sway bar endlink from strut: Use a 17mm open end wrench on the

flats behind the sway bar link joint to prevent rotation while loosening the

bolt with a 16mm socket/ratchet. Remove the sway bar link from the strut mount

after removing the bolt:

You may want

to soak the base of the strut to steering knuckle union with PB Blaster so that

it will come apart easily:

Remove the strut pinch bolt: After soaking both ends of the bolt

liberally with PB Blaster and allowing some time for it to soak in, I used an

18mm socket with a ratchet and/or breaker bar to loosen and remove the pinch

bolt. I also used anti-seize with this bolt on reassembly after reading some

nightmare stories on the forums of people breaking these off in the steering

knuckle due to rust-weld.

The

steering knuckle did drop but contrary to the Hotchkis instructions, the

knuckle did not drop enough to free the bottom of the strut- I had to compress

the suspension to remove the strut assembly after removing the three upper

strut mount nuts (next step below) in order to get enough room to clear the

knuckle. This will require some creative thinking on your part or a spring

compressor that works with the strut installed.

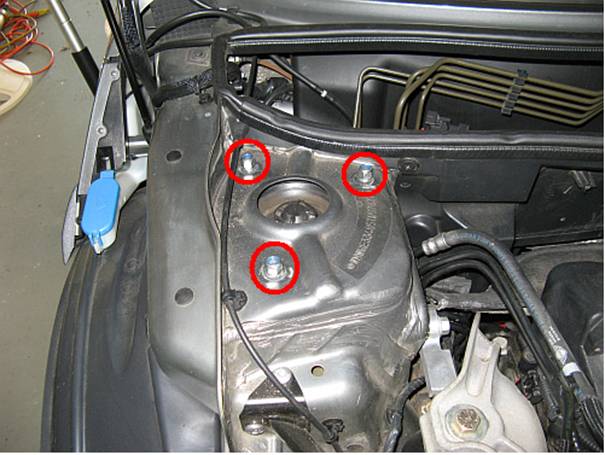

Remove the three upper strut mount nuts:

In my case this required a 13mm socket (OE nuts may be the same….or not):

With the strut removed, the plastic cover can be removed using a standard

screwdriver to access the nut:

There are

some different ways to remove the nut from the strut but none work better for

me than an impact wrench, I have air but electric works too. If you don’t have

access to one of these, I have used creative solutions like the one below in

the past- a 13/16 spark plug socket and the correct HEX wrench with Vice Grips,

no guarantees this will work for everyone or every car. Pic below is merely to

illustrate a potential alternative to an air wrench, in the past I would have

cut the hex wrench down so that the Vice Grips and the wrench on the spark plug

socket were closer together, and a closed end wrench on the spark plug socket

will always work better than an adjustable:

Compress

spring using a spring compressor, I have always borrowed one from a McParts

store like AutoZone using their tool loaner program:

After removing

the nut you will see that there is the spring, rubber insulator, top hat,

washer, strut mount, and nut in that order:

The only

items that will be re-used above the spring with the camber plate installation

are the rubber insulator and the nut. The rubber insulator is removed from the

OE spring hat and placed on the new Hotchkis spring hat:

Reassemble

the spring with the new Hotchkis spring hat, now is a good time to apply some

blue LocTite to the strut piston threads. The bearing goes on top of the hat,

and the nut holds it all together.

Make sure

the rubber insulators are aligned with the base and hat stops and that the

spring is tightly aligned at the rubber insulator stops on both ends. If using

the OE springs you may need a spring compressor for the reassembly step. With

my APEX springs, we were able to use the two man method- my son loosely started

the nut while I compressed the spring by pushing down on the spring hat,

finished off with the air impact wrench:

The plates

are installed prior to the strut assembly installation, they are left/right

side specific. This is also the point where you can check for possible

mushrooming issues and correct with a piece of 2x4 and a big hammer. I had some

slight strut tower mushrooming issues and the 2x4/5-lb hammer method took only

a few minutes to repair them:

Before

attempting to install the assembly, I turned the Hotchkis strut bearing by hand

to orient it so that it would fit the plate when installed using the pinch bolt

tab on the strut housing as a reference point to align with the rounded end of

the bearing mount. It is TIGHT and will be hard to turn by hand when installing

into place. The alignment plate and bolts on top of the plate were loosely

started before tightening everything up, Hotchkis suggests using blue LocTite

on these bolts. TIS torque specs at bottom of this write-up for your reference,

installation is reverse of removal. Don’t forget to secure the brake line and

brake sensor wire on the strut:

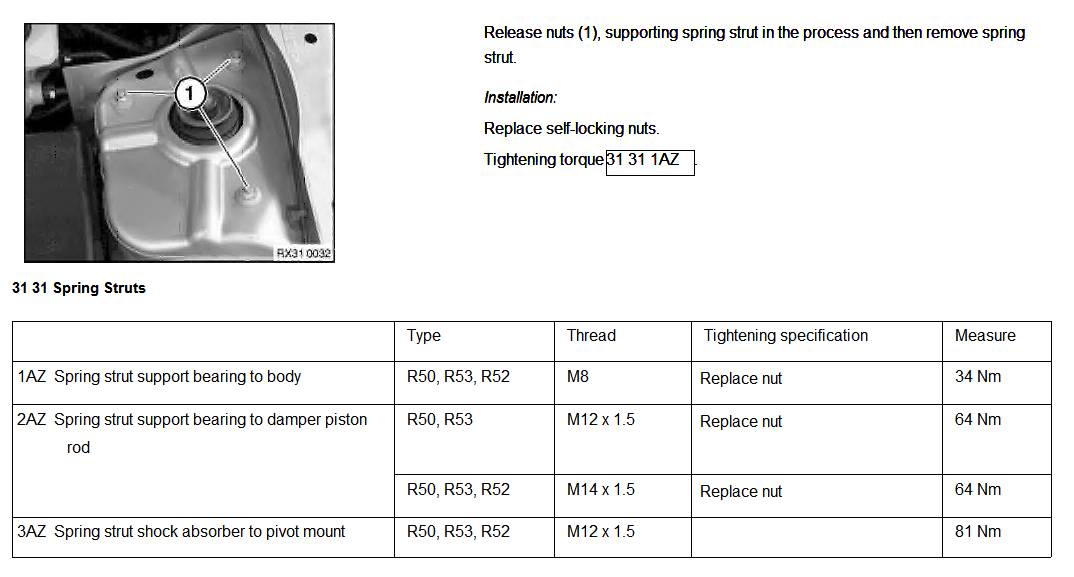

TIS Instructions and Torque Specs: