R50-R53 Mini Cooper

Power Steering Pump / Fan / Duct

Replacement and Installation

The power

steering pump and fan are known issues with our Mini Coopers. My pump died a

short while after I purchased my pre-owned Mini with 110k miles on the clock.

The fan still worked but felt rough when turned by hand off the car at certain

points, I figured since the pump was being replaced the fan was cheap

insurance. I also purchased the OE duct for the fan to offer some protection

from road debris.

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK.

To start,

I disconnected the battery by removing the ground cable using a 10mm

socket/ratchet. You may want to place a shop rag or newspaper over the latch so

the hatch will not lock, if it does you will have to use the manual release

under the rear seat:

I used my

Topsider to vacuum the power steering reservoir dry. I was also able to get it

down the suction hose from inside the front of the reservoir to drain all the

fluid out of that tube. No such luck with the rear hose since the baffle in the

reservoir was blocking access.

The car

was jacked up using the common piece of wood under the chassis rail with jack

technique (technique in more detail on NAM), this allowed jack stands

to be placed at the factory jack points. Be sure to get the car high enough so that

you have room to work. Also, the parking brake should be on and the rear wheels

chocked prior.

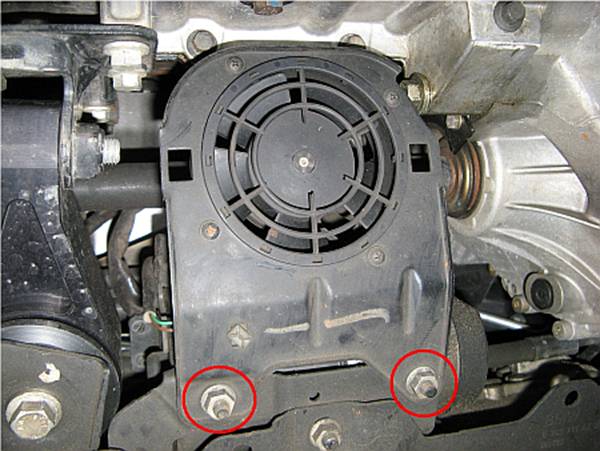

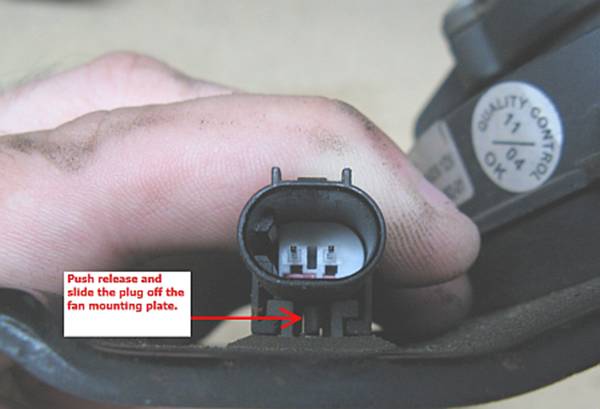

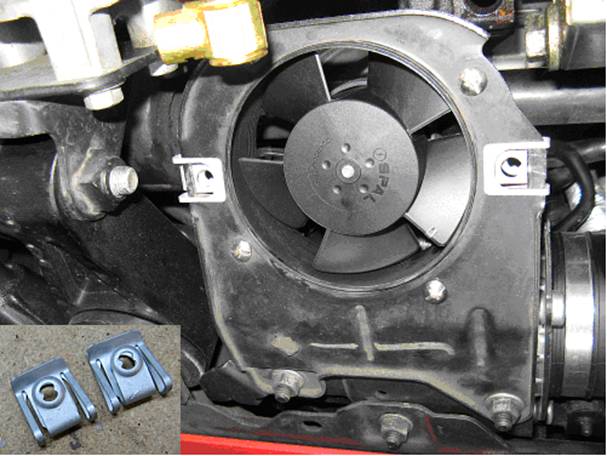

The fan is

removed using a 13mm socket wrench, two bolts hold the fan to the pump bracket.

The wiring harness plug is released by pressing on the tab and pulling.

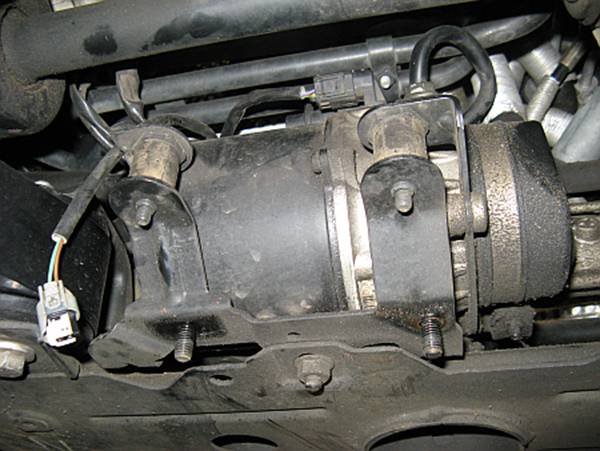

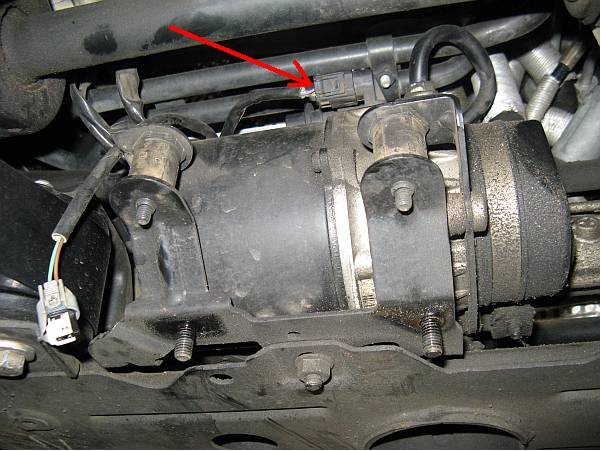

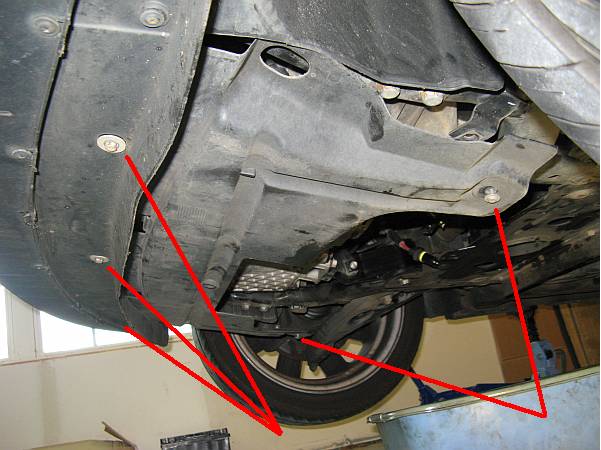

On to the

power steering pump- The first thing removed were the two top bolts holding the

Power Steering Pump (PSP) in. The first pic below shows a view of the back of

the front subframe where the cat resides, going closer and at a higher angle

you will see two bolts that need to be removed (the orange sticker is a good

reference point when looking at the pics). I used a 13mm socket and a 3/8”

ratchet with two small extensions to remove these, once you know where they are

at you can remove/install these by feel:

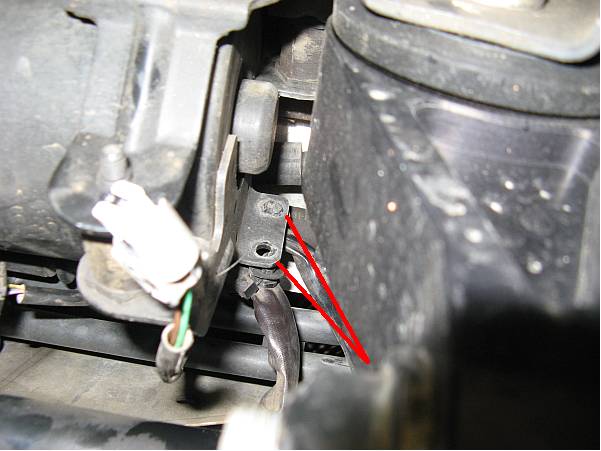

If you

look above the motor mount at the passenger side of the PSP, you will see the

wiring harness retainers pushed into two holes on the PSP bracket, these can be

pushed up and out of the bracket:

The

suction hose clamp can be removed by inserting a flat bladed screwdriver in the

clamp recess and twisting- you may have to twist both ways a few times to get

it loose and then pry the clip apart:

The lower center

bolt holding the PSP bracket to the car can be removed using a 13mm wrench:

The small

wiring harness plug at the top of the PSP can be removed by pressing down the

clip and pulling off:

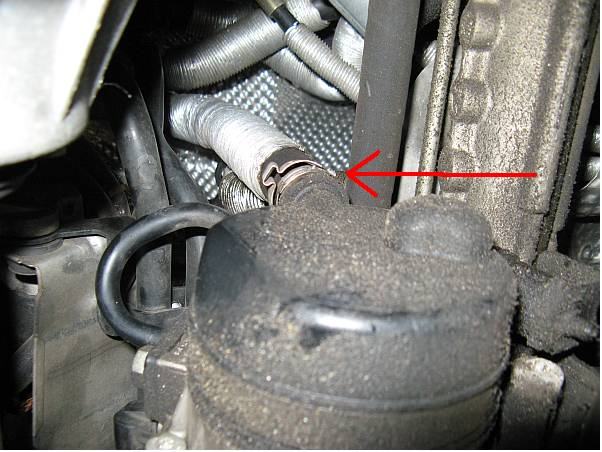

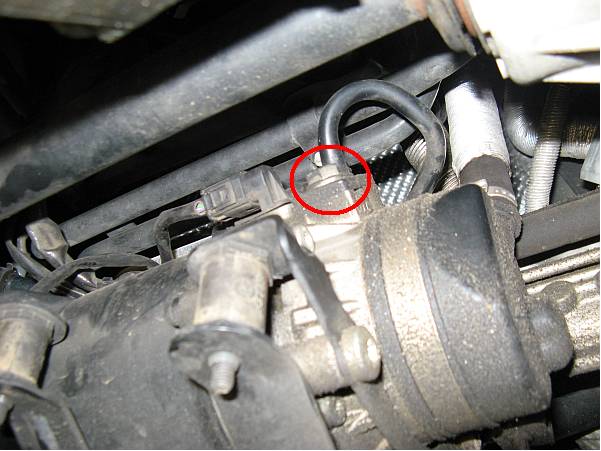

The

pressure hose is held to the PSP by a bolt that will need to be removed, using

a 13mm wrench. After the bolt is removed, it will take a bit of pulling to get

the hose fitting out of the PSP, it is a precision fit and there is an O-ring

(see arrow in pic) on the hose fitting. Don’t lose the O-ring unless you have a

new one to replace it (which might not be a bad idea, P/N 32416762724, 8mm x

2mm, #15 illustrated HERE). Have an oil pan and some shop towels ready as this

hose was the one not accessible to drain and there will be a bit of fluid. The

suction hose (the one with the clamp I had to pry apart) can be pushed up and

off of the pump, not much fluid in that one other than a few drops thanks to

the Topsider:

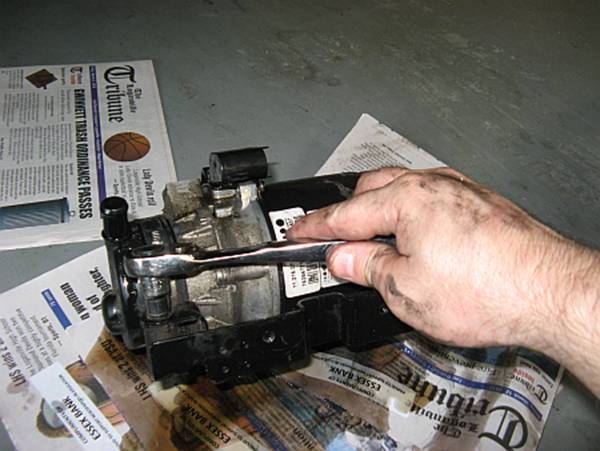

Take a

break while the fluid is draining, after it is down to a drip you can remove

the PSP with bracket. Some forum guys have used a Dremel tool to slot the lower

bolt hole to make this easy to slide out. I found that by tucking all wiring to

the side and pushing the hard line out of the way, the pump could be tilted

toward the front of the car and pushed up and over the subframe bolt hole- it

IS tight but there is enough room to clear the bolt hole without any

modification (unless you want to). Once the PSP and bracket have been wedged

clear of the subframe, the main power connection plug can be removed by pulling

out. It looks like this plug has retainers but they give with pulling force, no

prying needed:

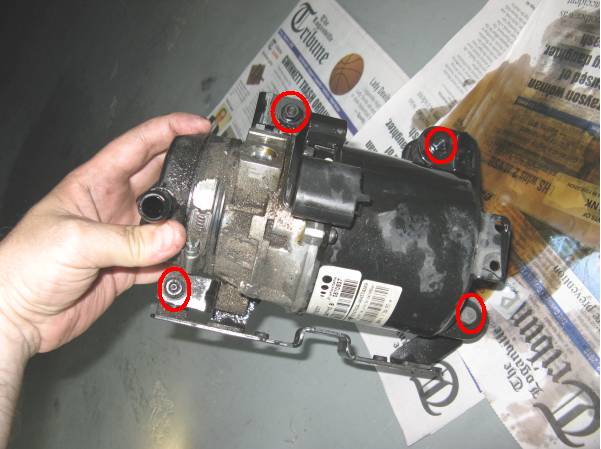

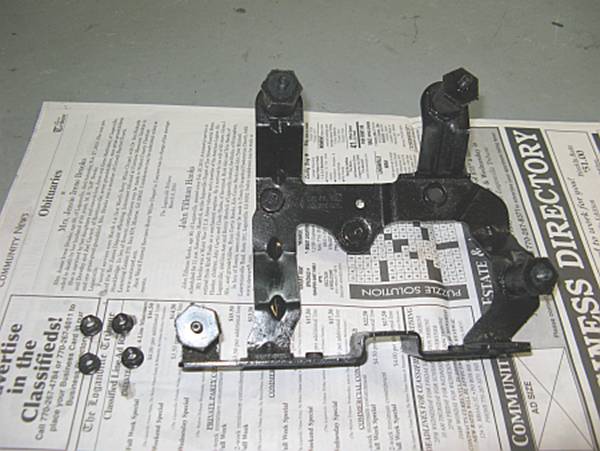

The pump

bracket is removed using a 10mm wrench, 4 nuts total:

With the

above bracket removed I was able to access the other bracket that will need to

be removed using a T40 Torx socket, 2 bolts total:

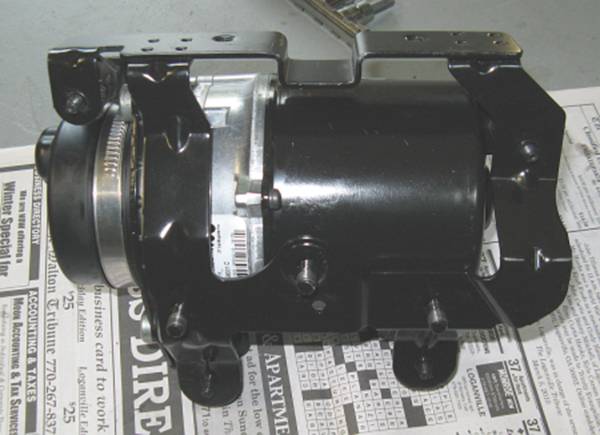

Brackets are

attached to new pump (after cleaning them up a little first):

You will

need to source a 1” hose clamp to replace the non-usable OE clamp that was

removed from the suction hose. I went ahead and pre-tightened this clamp a bit

and placed it up the suction hose and on the hose heat shield so it would stay

in place while the new pump was installed. I also cleaned up the pressure hard

line connection making sure no dirt was on the O-ring and surrounding area:

Before

attempting to reinstall the new pump, the pressure port plug is removed- you

will not be getting this out with the pump in place. The suction port cap is

left in place since it is easily removed once the pump is in place and will

only help to keep dirt out when reinstalling. The pump is installed the same

way it was removed: the main power harness is plugged in; pump is installed by

rotating it into position and the lower bolt into the hole. Once in position,

the top rear bolts are installed first- I used a shop light to visually line up

the bracket holes and then used the socket wrench extension/13mm socket to get

the bolts hand started, then tightened using a ratchet. Next the lower bolt is

tightened using a 13mm wrench. The pressure/hard line is pushed in (it is a

good idea to lube the o-ring with some new power steering fluid prior to

assembly so it will slide into place) and that retaining bolt inserted/started

by hand/tightened using a 13mm wrench- you may have to rotate the hard line

around to get the hole to line up with the bolt hole. The suction hose is

pulled down and over the male hose fitting on the PSP after removing the

protective cap, and the hose clamp put in place and tightened- not gorilla

tight since the hose fitting on the PSP is plastic. The smaller wiring harness

connector is plugged into the PSP, not to be confused with the fan wiring

harness plug. Do not forget to also push the two wiring harness plastic

retainers back into the bracket holes on the passenger side.

I bought a

new fan that has to be installed on the fan bracket. Since this fan is a

standard SPAL P/N and not the Mini specific part, new screws and bolts will

have to be sourced (the standard fan screw holes are too large for the Mini

screws) and the Mini fan connector cut off the old fan and spliced into the new

fan wiring harness.

I was able

to find three of the same slightly larger sheet metal screws to hold the new

fan to the mount until I get to the hardware store

to

purchase 4 new bolts/nuts/washers for a permanent fix. The connector on the old

fan was cut far enough back to leave plenty of wire to splice into the new fan

wiring harness. I removed the spade clips from the new fan connector and cut

them off to maximize wire length there as well. I used crimps and a crimping

tool to splice the connector and wiring harness but you may want to solder or

both- my personal experience has shown crimps only to work well in automotive

use- YMMV.

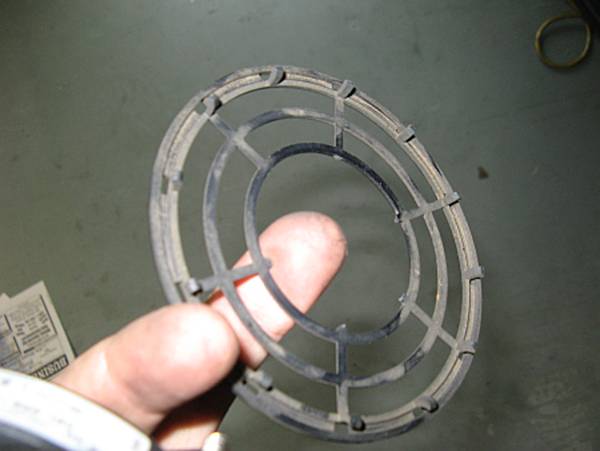

The grille

is removed from the fan by carefully flexing it out and off, this is no longer

needed and would interfere with the duct I am installing.

You will also notice that where the duct screws would go, there are two square

voids where the OE “screw” retainers (P/N 07146981767 x 2, #8 illustrated HERE) would clip into place . Since I did not get those

pieces, I found some sheet metal screw clips that would work but may order the

OE pieces. The OE “screw” retainers were removed from the duct so that standard

screws could be used. If you have an older fan bracket that does not have the

duct provision, you may have to drill holes and change out the screws like I

did. Note the water drain hole in the duct. The fan is plugged in and

reinstalled using a 13mm wrench for both nuts.

[UPDATE: I

did order and install the OE “screw” retainers for the fan mount- pictures

below updated to reflect this]

The duct

requires a new piece to be installed in front. The old piece is removed by

loosening (but not much and not removing) bolts at the leading edge, by

releasing the “screws” on either side, and then pulling back and out:

The new

panel is pushed into place and the bolts/screw retainers tightened. The duct is

placed above the new panel vent and the screw retainers tightened, then the

screws are tightened at the fan bracket:

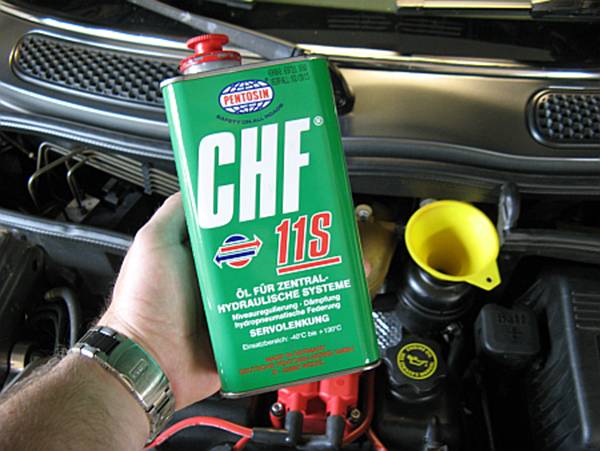

Don’t

forget to reconnect the battery. Last but not least, Pentosin CHF 11S fluid is

added to the power steering fluid reservoir. I started at a little over half a

can (add until it reads on the stick between the first and second line) and

added more as the bleeding process took place. Bleeding is accomplished by

having a helper start the car while it is still on jack stands and turning the

wheel from full lock left to full lock right a few times. You don’t want to do

this with the wheels on the ground and loaded as it might stress the pump until

you get the fluid in and the air out. Check fluid periodically on the stick,

add if fluid is not between marks, and repeat until satisfied. This is also a

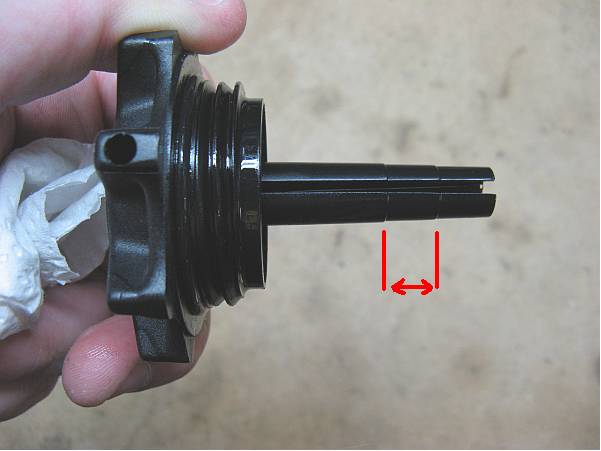

good time to check for leaks. After I was happy with the bleeding process, had

lowered the car off jack stands, gone for a drive, and then returned home to

check the fluid I probably used ¾ of one can. The fluid level is good when it

is between the first and second lines on the dipstick when warm:

After cleaning everything up you

can enjoy your Mini with power steering again J

For more information on products

used in this DIY guide and where they were sourced, check out my Mini website

at www.billswebspace.com/mcs.htm

For

more information on cleaning your PSP motor, check out this Mini2 thread HERE