Installing Cabrio

Braces on an R50/R53 Mini Cooper

Cabrio

braces came installed on Mini convertibles to stiffen the chassis and eliminate

rattles. These braces can only help the hard top and at the price of ~$45 they

are hard NOT to buy and install just to know you have done all you can do. I

purchased mine from Way’s online store (Way

Motor Works), he includes both braces and the eight Torx Head bolts

required. Some early build Minis do not have the required bolt holes so I would

check your pre-2004 build car before ordering.

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK.

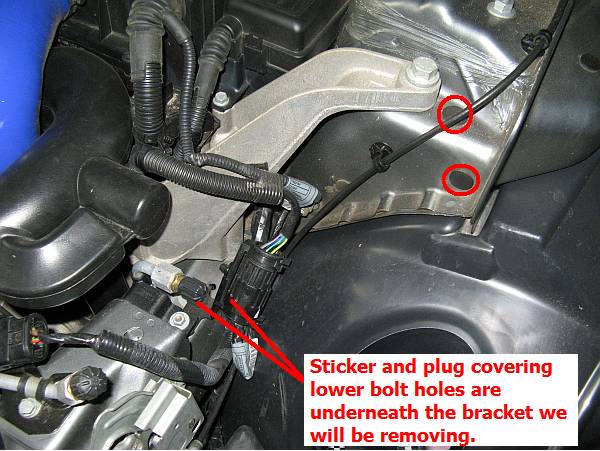

You can

see, looking at both sides, the plastic plugs where the bolt holes for the

brace are:

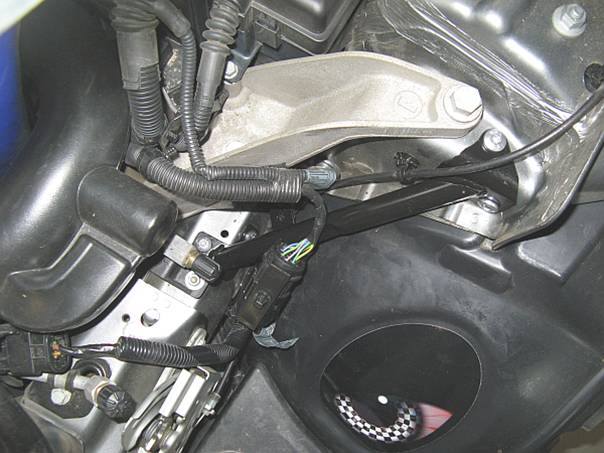

The driver

side (left side

There is a

wiring plug that is attached to a metal bracket, using angled needle nose

pliers the retainer ears are pressed down and the plug is released from the

bracket:

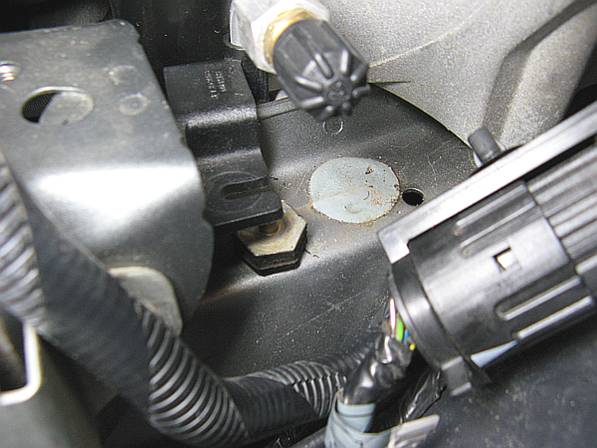

Using a ¼”

ratchet with an extension and 10mm socket, I removed the single nut holding the

plastic hose bracket down to the rubber spacer on top of the metal bracket we

want to remove. After the nut is removed and the plastic hose bracket moved to

the side, the rubber spacer can be unscrewed by hand (or maybe with a little

help from some pliers); it is screwed into a bolt hole in the car. The bracket can

now be removed.

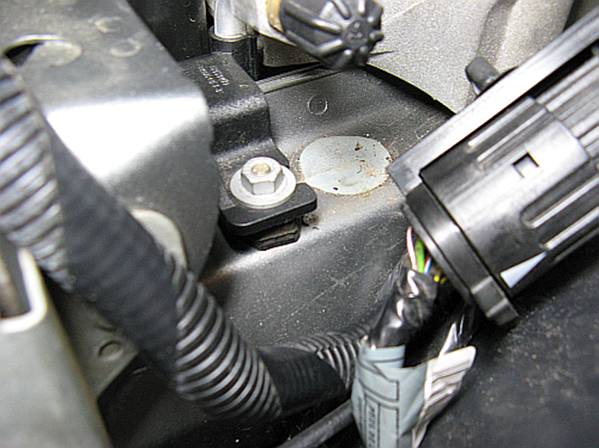

The rubber

spacer is screwed back into the car and the bolt holding the plastic hose

bracket down is replaced and retightened:

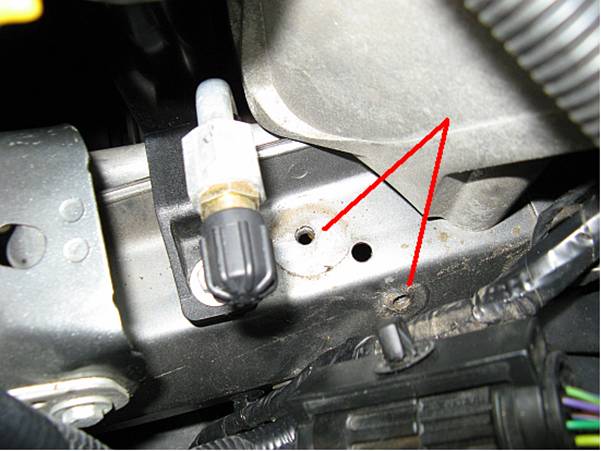

The

sticker is peeled off and the three plastic plugs are removed carefully using a

screwdriver and/or needle nose pliers:

NOT

PICTURED STEPS- I also removed the plastic caps on the passenger side (right

side

The brace

on the driver side has to be located among some wiring looms so carefully feed

it through using pictures below as a reference. You might note that the brace

for this side has a bracket with a hole that replaces the bracket we removed

earlier. The Torx bolts are started by hand in all holes and tightened

gradually moving from bolt to bolt using a T30 Torx driver until hand tight.

The bolt on the side of the lower rail is a PAIN to get to when hand starting

and even more painful to tighten. You will be able to reach this bolt to

tighten it by carefully maneuvering the driver through the wires and pressing

the handle against the plastic fender piece (the piece that is behind the

headlights when the hood is closed), it will flex

enough to give you some room to turn the handle until the bolt is tight. After

all bolts are tight, the electrical connector retainer can be pushed into the

brace bracket.

Moving to

the passenger side, the installation is much easier without the wires to work around

although the lower side bolt is still a little harder to get to than the others

in order to tighten:

Completed

installation on the dirty car: