Installing an R53 Mini Cooper

Header

I had read

on the forums that as the factory exhaust manifolds

aged they had a tendency to develop cracks, and this was a good enough reason

for me since I wanted a header anyway. I found a GREAT deal on a slightly used

(few weeks) SuperSprint Header and new high

performance metallic cat and that clinched it- out with the old exhaust

manifold and restrictive pre-cat/cat and in with the new SuperSprint

header and performance cat.

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK.

I used

Randy’s DIY guide HERE

to get a feel for what was required and involved.

You may

also find the TIS instructions helpful: Exhaust System R&R HERE,

Exhaust Manifold R&R HERE

Since I was

also removing the OE exhaust and installing a new system, I raised the car up

at all four corners using four jack stands. You only need to really raise the

front with a header only installation.

The

exhaust is disconnected from the exhaust manifold/catalytic convertor assembly

using a 15mm wrench. I have read that some Mini Coopers do not have the same

pressed-in stud and nut setup I had so you may need to adapt this step to fit

your specific scenario. Now is also a good time to remove the post-cat O2

sensor using a 22mm wrench. Looking above the pre-cat

you will see the pre-cat O2 sensor, also removed with a 22mm wrench- this one

is a little tougher to access, you just have to figure out the angle of attack

and it may be easier to do with the driver side heat shield removed.

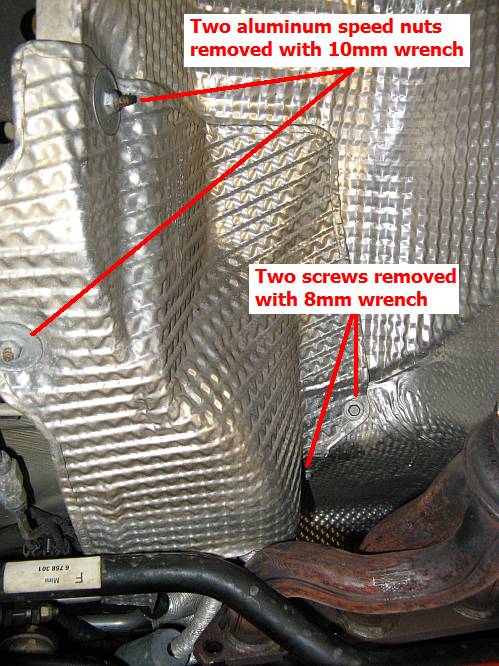

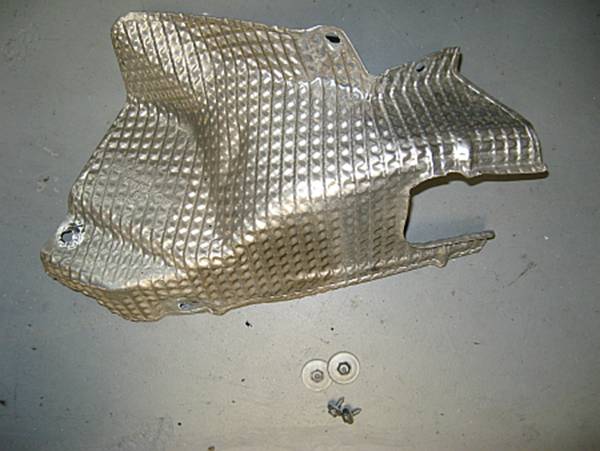

I went

ahead and removed the driver side heat shield, two speed nuts removed with a

10mm wrench and two screws removed with 8mm socket wrench. Removing this heat

shield not only allows easier access to the top/pre-cat O2 sensor but is a MUST

for getting the exhaust manifold out of the car.

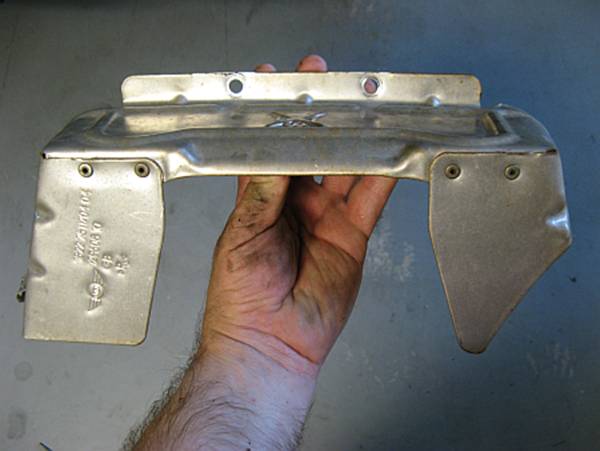

Back up

top, there is a heat shield that needs to be removed- two bolts removed using a

13mm wrench and it helps to bend the rear heat shield up and out of the way:

Now you

can see the OE exhaust manifold and the eight bolts you will need to remove

requiring a 10mm socket wrench- a narrow headed wrench is much easier to use

because space is tight:

The

exhaust manifold can be carefully lowered until you get to a stopping point- I

also moved the upper O2 sensor out of the way before lowering and carefully

placed it to the side:

Getting

the exhaust manifold out around the front sway bar is a little tight but

doable, the trick is to push it as far to the right as possible while hooking

the left side over and around the sway bar- you may need to use a little force

since it is tight between the sway bar and body of the car:

Comparing

the OE exhaust manifold to the new header, it is obvious to see where there was

room for improvement:

I cleaned

the head mounting surface and used a new OE Mini exhaust manifold gasket before

bolting down the new header. I used an alternating pattern to tighten bolts

starting with the center bolts and working out on each side. The torque spec is

in the TIS document linked at the beginning of this write-up:

I had to

modify the heat shield, some have cut theirs but I removed the rivets and bent

it into a more header friendly shape after bolting back in. I made sure there

was plenty of room for vibration/movement without possible contact so no

rattles:

Don’t

forget to bend the rear heat shield back down:

I had to adjust (bend) the heat shield above the power steering pump slightly so

that it did not contact the header. Some of the other

heat shields may need massaging as well:

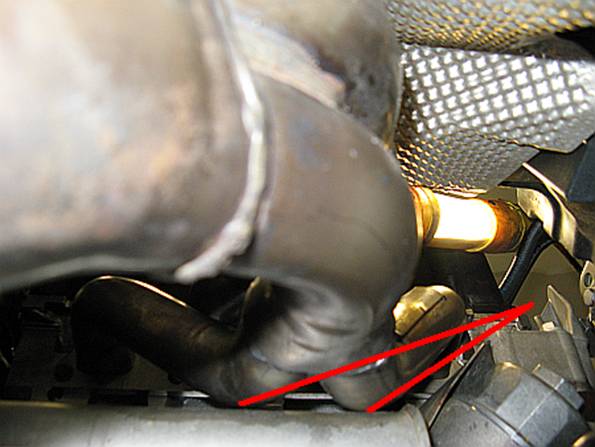

The

upper/pre-cat O2 sensor was installed:

Next the performance metallic cat was installed- the donut gasket and then the

cat and post-cat O2 sensor:

Finally

the exhaust can be connected using a new OE Mini cat gasket or a thicker cat

gasket with a larger inside diameter. I could not find one that was perfect but

did find one that was close- I made it perfect (a little larger ID) by placing

it on the exhaust mid-pipe flange and using a ball peen hammer around the

inside hole to cut away the excess before installing. I had some bolts in my “mystery

box” that were from an old car exhaust that worked perfect here, I have read

M10x35 should work:

Enjoy a little more sound and

power…………..