BMW E92 M3: Installing H&R

Sport Plus (Race) Springs

The M3

comes with very capable suspension; ours has EDC (Electronic Damper Control) so

it can adjust to suit most conditions/people. However, I was looking for a bit

more road feel and sharpness and H&R provided this in the form of Sport

Plus (Race) springs. This installation is the EASIEST spring swap ever, the DIY

guide I used to do this can be found at http://www.m3post.com/forums/showthread.php?t=183011

Start to

finish with breaks and stopping to take these pictures took me about 2.5 hours,

but allow more time if you are not an avid DIYer.

I found

some lightly used springs in the forum classifieds for a deal, they are a GREAT

place to save on mods before buying new.

Also, if

you are installing springs and have not done so already, you may want to remove

the factory strut alignment pins to allow max negative camber, detailed on my

M3 page HERE.

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK, I ASSUME NO LIABILITY FOR YOUR USE OF THIS

INFORMATION.

Front Installation:

I like to

tackle the most difficult part of an installation first so in this case it was

the front driver side. The driver side front and rear have headlight leveling

switches that need to be disconnected before dropping the suspension which adds

a step, and the front is considered to be more difficult than the rear.

Before

lifting the car, break all of the front wheel lug nuts loose, but don’t remove.

The car can be jacked using the central jack point and then jack stands are

placed under the OE side jack points:

Once on

jack stands, the lug nuts and wheel can be removed and you will see what you’re

in for:

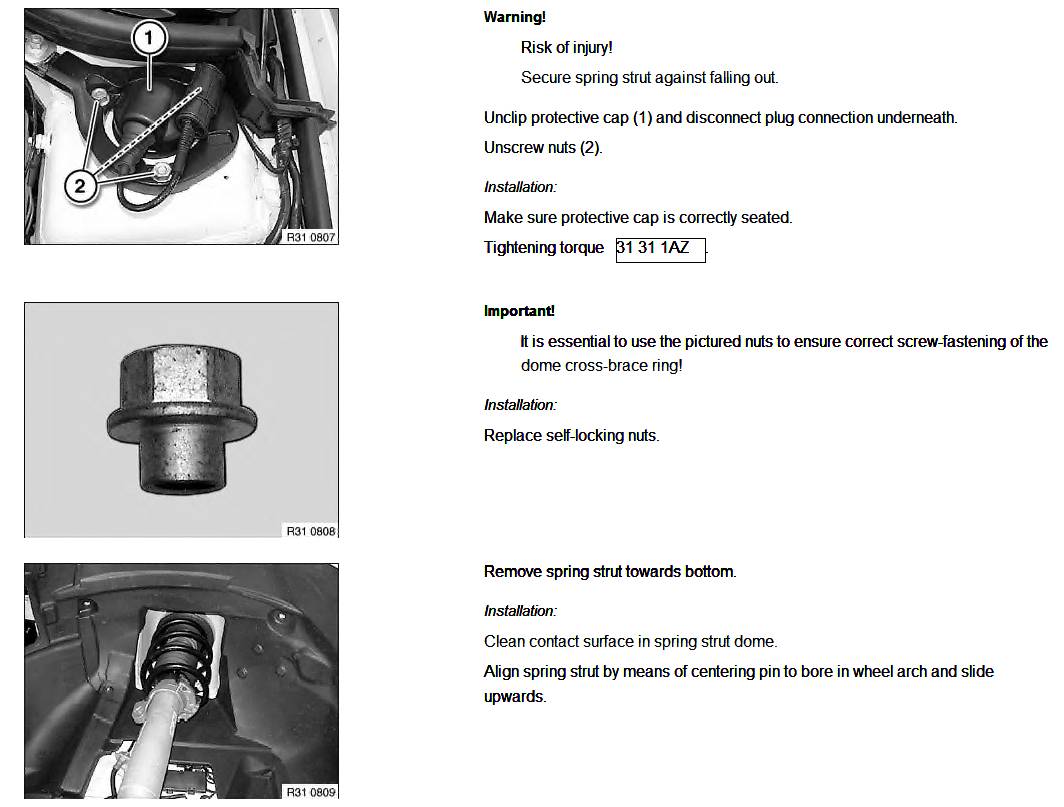

I started

under the hood by breaking the strut nut loose, the EDC controls have to be

removed to access this. Unplugging the wiring harness by pressing the two

release tabs, and gently lifting the EDC cap up you

will see a small plug where it connects to the damper. This plug can be

disconnected by lifting straight up- no release:

With the

EDC cover out of the way, the strut nut can be loosened (don’t remove yet)

using a 10mm socket wrench to hold the strut piston rod and a 21mm wrench to

break the surrounding nut loose. I attempted to use painters tape to prevent

the strut brace ring from getting beat up, even though the tape looks ripped it

did its job:

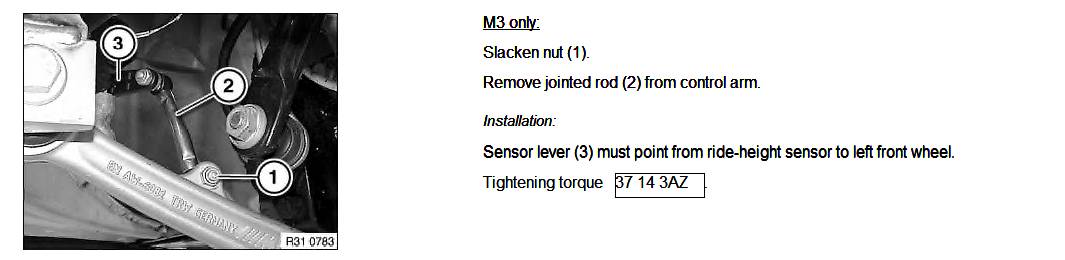

Back under

the car, the headlight leveling switch can be disconnected from the lower

control arm using a 10mm open end wrench on the flats behind the bracket and a

10mm socket wrench to loosen and remove the nut. I replaced the nut so it won't be lost

and tucked the switch arm up out of the way:

Sensor

wiring and brake lines are pushed out of their respective holders on the strut

tube:

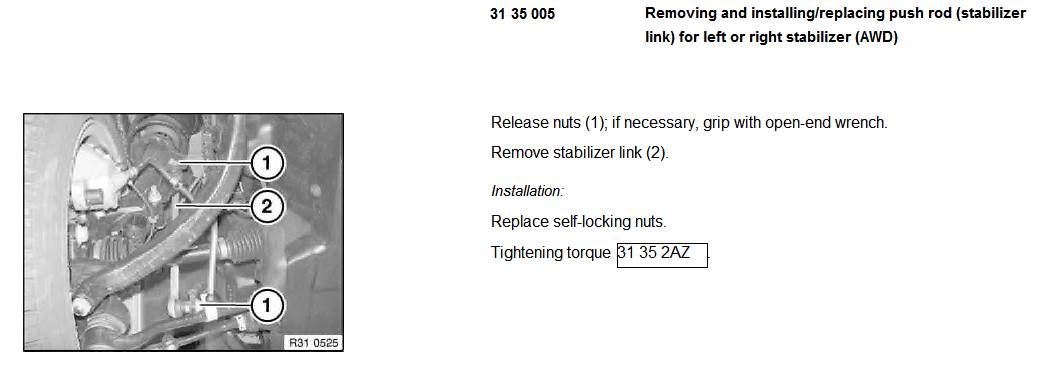

The sway

bar link is removed from the strut housing, a 19mm open end wrench is used on

one side to keep the ball joint bolt from rotating and a 16mm socket wrench is

used to remove the nut. The nut is replaced so it won't be lost and the link is

positioned out of the way:

[CAUTION: An

automotive spring can exert a LOT of force that can cause injuries- Please

proceed at your OWN RISK]

I

compressed the spring by placing a jack under the lower ball joint and jacking:

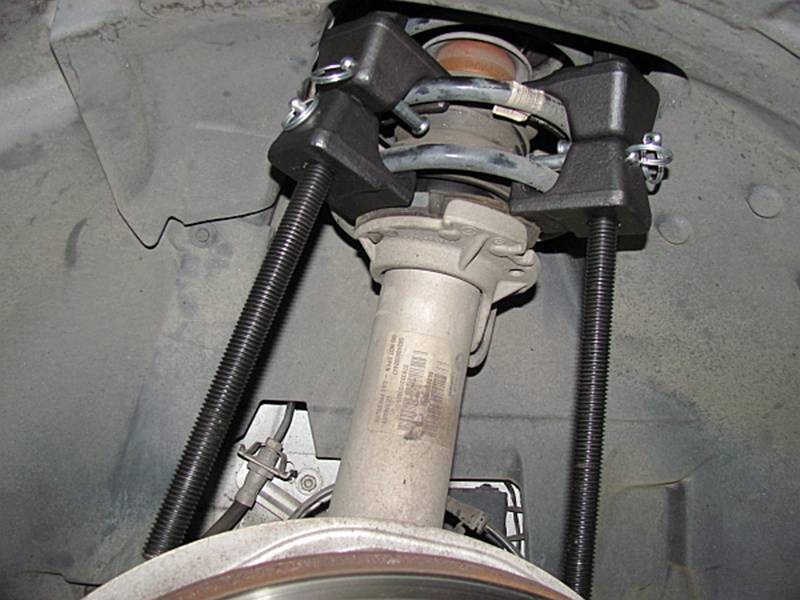

With the

spring compressed, spring compressors can be installed by hand and tightened on

two of the lower spring coils. The spring compressors seen here are available

through the FREE loaner tool program at AutoZone:

The 10mm

socket wrench and 21mm wrench are again used on top to completely remove the

strut nut:

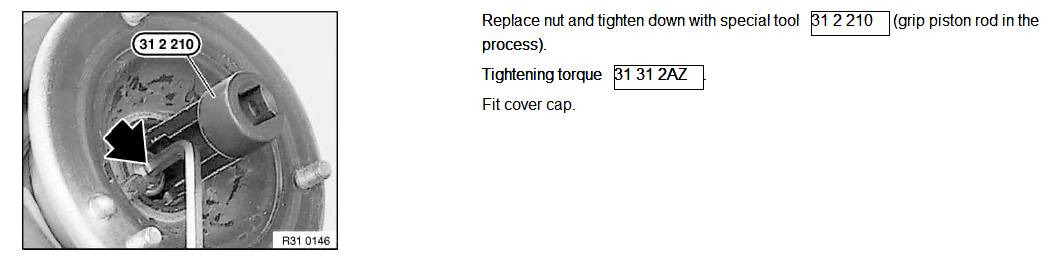

The

jack can be lowered to allow the strut to drop down/free. You may have to use

your hands to push the strut piston down to allow it to be pulled out to the

side and clear the fender, the spring might need a little help as well. If the

strut bearing cover comes out with the assembly it can be reinstalled by

pushing up and back into place. The spring compressors can be carefully removed

from the spring, you will not need these to reinstall the strut with the

H&R springs:

Front

spring is installed, making sure the spring ends line up with the upper and

lower spring stops, and all above reassembled and installed: strut piston rod

nut (using jack to raise/hold in place as the assembly is aligned and

reinstalled), anti-roll bar link, all hoses/wiring clamped back into strut tube

holders, and for driver side the headlight leveling switch is reconnected to

the lower control arm. Passenger side can be completed using the same steps.

TIS Torque specs and instructions at bottom.

Rear Installation:

Similar

to prep steps used in front, the car is jacked at the rear center support and

jack stands are placed under the side rear jack points. It is NOT advisable to

jack using the differential. ALWAYS USE WHEEL CHOCKS IN FRONT OF THE FRONT TIRES (you can't see them in the pics because they are some small collapsible chocks from an old 280Z but they are there):

Once on

jack stands and with the parking brake on, the wheel lug bolts can be removed

along with the wheel:

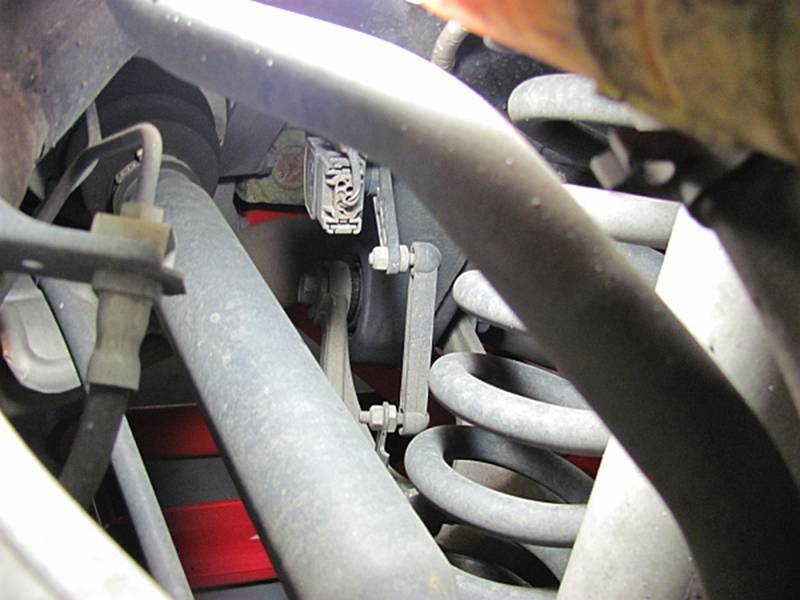

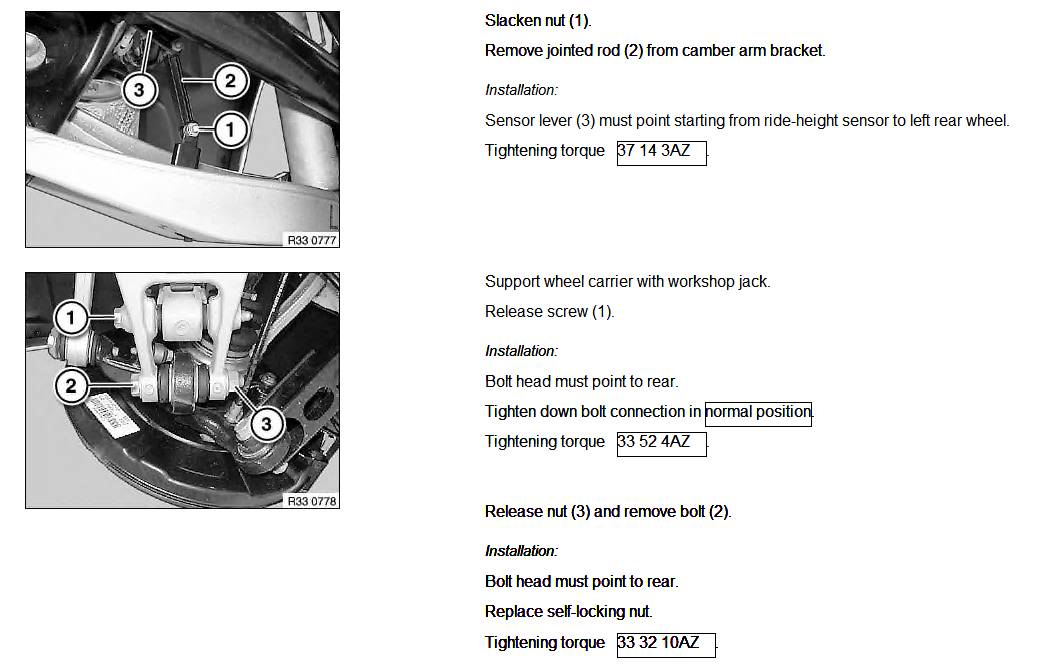

The

driver side has the headlight leveling switch; it can be removed as in front

using a 10mm wrench and a 10mm socket wrench and placed out of the way after

the nut is reinstalled so it won't be lost:

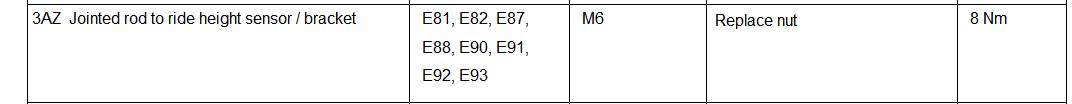

The

lower control arm is supported with a jack under the solid area below the

spring:

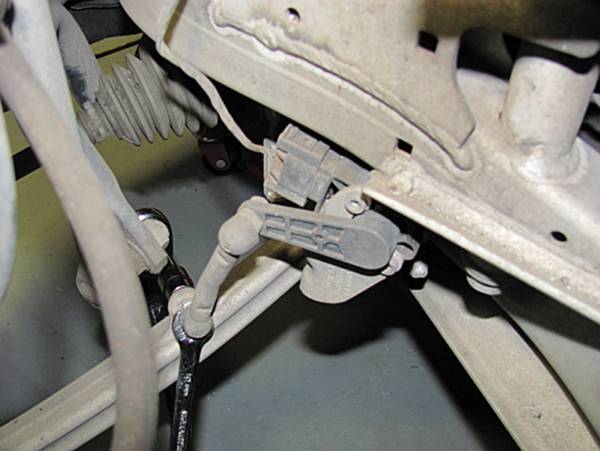

The

lower control arm has two bolts that will need to be removed, the shock bolt

and the wheel hub bolt. FIRST, the shock bolt can be removed using an 18mm

socket with a breaker bar at first and then a socket wrench. NEXT, the wheel hub

bolt is removed using a 21mm wrench on the nut to hold while a breaker bar then

socket wrench are used with a 21mm socket to remove the bolt:

The

jack can be lowered once both bolts have been removed. The lower control arm is

pushed a bit further down with one hand while the spring is removed with the

other. I did this by pushing the spring down and out of the upper cup, and then

lifting up and out of the lower control arm:

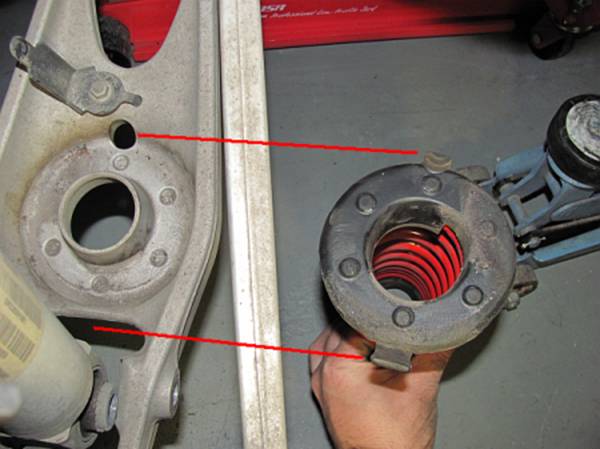

The

new spring is installed making sure the lower and upper rubber stops are

aligned with the spring ends. The lower rubber insulator has two tabs, the

smaller tab fits through a hole in the control arm and the larger tab fits the

larger rectangular hole facing toward the side of the car:

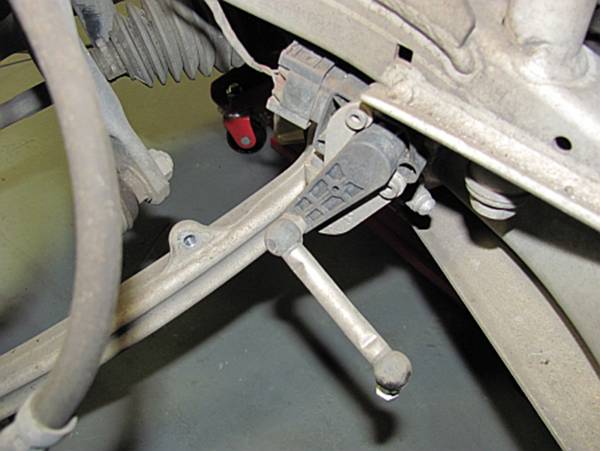

The jack is

used to jack the lower control arm back into place; you will have to play with

it a bit to get the optimal height and alignment to get the bolts through.

Install the hub bolt/nut FIRST (a little tricky to align, once you figure it

out the other side will be easy), and NEXT the shock bolt (careful not to cross

thread the bolt). You can use a screwdriver in between the hub mounting point

and shock base to get it aligned. The final tightening to specific torque

values should be done with the suspension at normal height; this can be done

with the wheels remounted and the car backed on to ramps- TIS torque specs and

instructions at bottom:

Don’t

forget to visit your tire shop for a 4-wheel alignment…………….

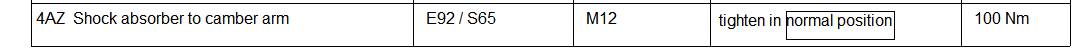

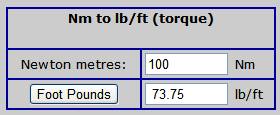

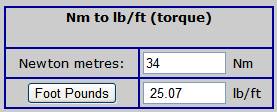

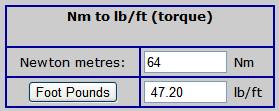

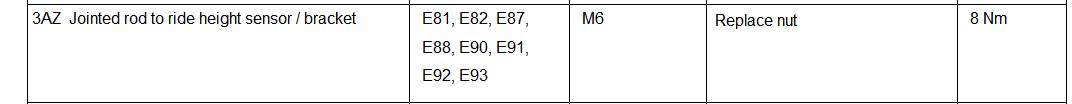

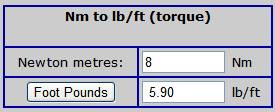

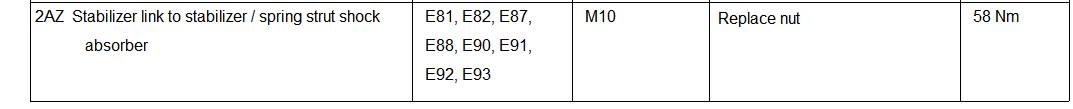

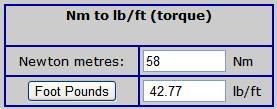

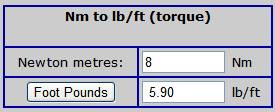

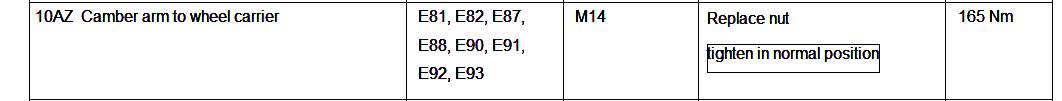

TIS Torque Specs: TIS instructions below with torque

specs-

FRONT:

![]()

![]()

![]()

![]()

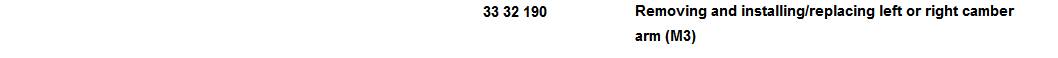

REAR:

![]()

![]()

![]()