40K Elise: Changed My Lift Bolts /

By moremonkey’s

Stan

I had a chance to pop my

valve cover today. I wanted to look things over and check out my lift bolts.

Here are some pictures and comments.

I can do a lift bolt

changeover write-up if folks are interested. Basically they are a wear item in

the cam changeover gizmo and sometimes they break. Once your valve cover is off

(10 minutes or so, a trick or two but easy) they just unscrew and you load in

the new ones. They cost me 98 cents for the two you need, one bolt per cam. The

valve cover goes back on easily, there are a few things to line up, you need a

dab of glop near the chain cover and you reuse the rubber gasket.

Lift Bolt:

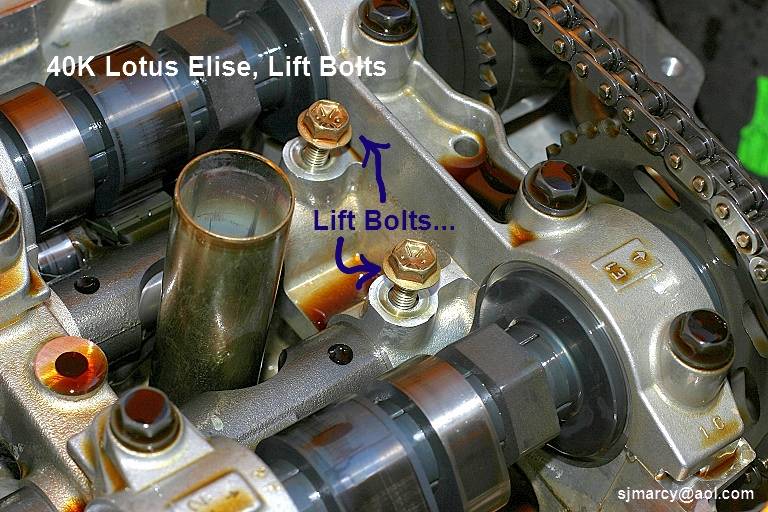

Here is the head with the

valve cover yanked...clean as a whistle, synthetic oil baby.

Here is a closer view with

the lift bolts unscrewed.

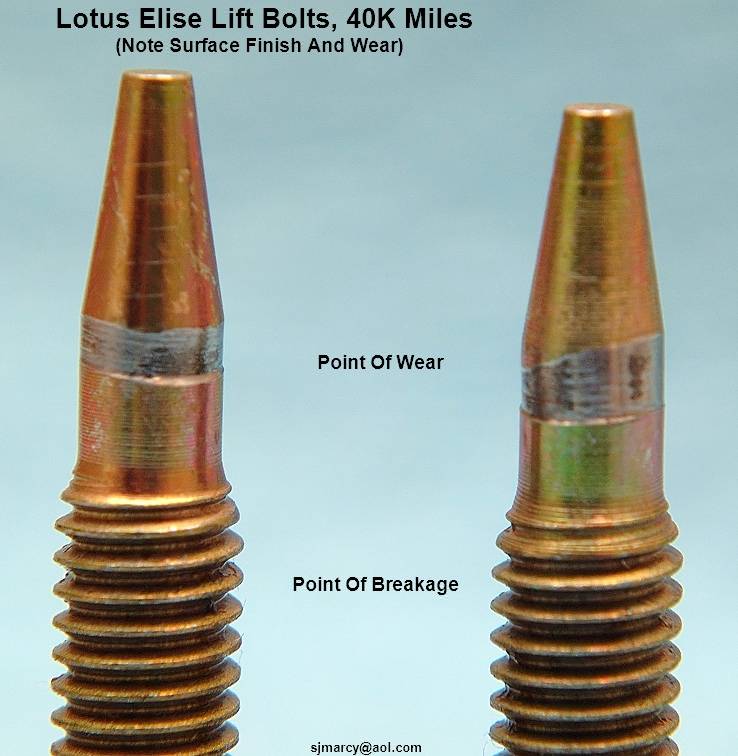

New versus old bolts...see

the wear pattern? There is a ridge and the wear goes all the way around the

bolt.

Another view...

I am glad I changed the

lift bolts. If the bolt breaks off it is a pricey repair and you can't hit the

big cam in the mean time.

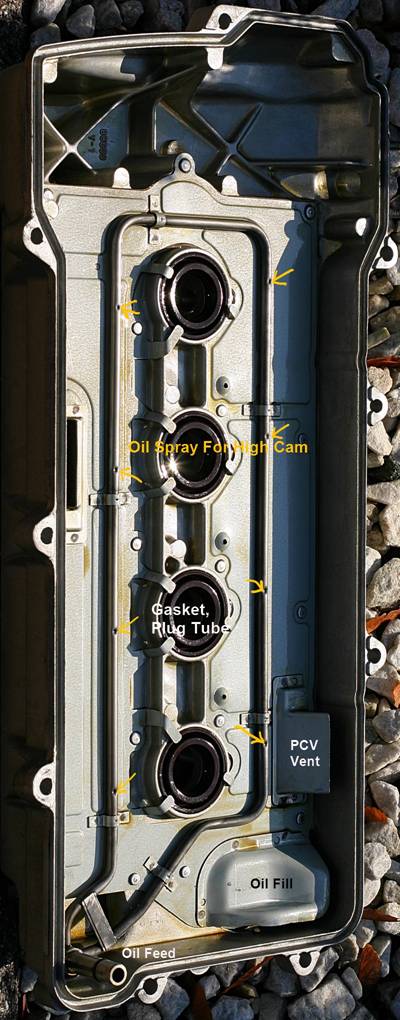

Underside

view of the valve cover. Note

the lubrication plumbing designed to aim at the high cam lobes and keep them

alive.

A closer view; The tube lives in the corner near the trunk and oil fill

cap.

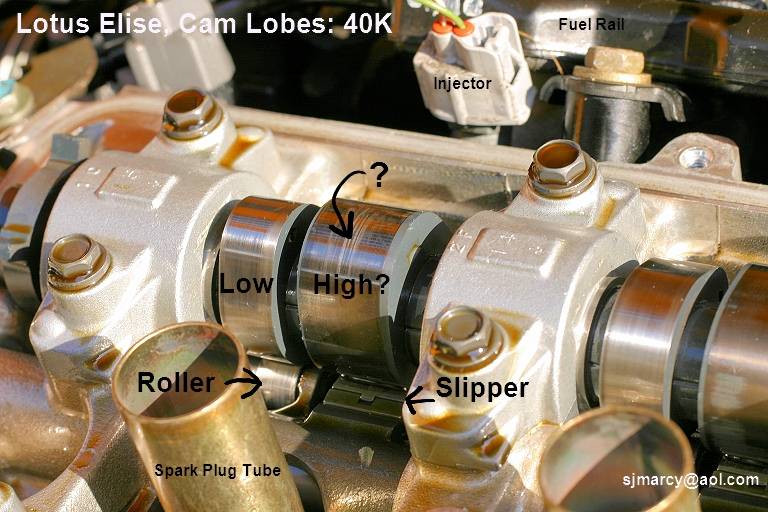

Some high cam lobes have the ? appearance. No pitting or

scratching if you test with a fingernail. Maybe that is some remaining coating

(see lobe sides). Also note the roller VS slipper concepts. The low cam uses a low

friction roller lifter...they are undemanding lubrication-wise due to the

rolling and not sliding/rubbing action The high cam slipper sees very high

rubbing loads, which requires some extreme pressure (EP) functionality from the

oil. Note that such additives have been reduced several times as the API

certifications SL, SM, etc have progressed. See:

http://www.monkeytuner.com/forum/viewtopic.php?t=554. I'd want to use a proper

oil to protect the high cam if I was on it a lot... The API has capped such additives

because they suspect that catalytic converters will get coated in about 8-12

years of normal car mileage. Your converter still flows, it just cuts

pollutants less. The additive issue is more of a concern for non-roller cams

and for piston rings in certain cars.

Here is an overall view:

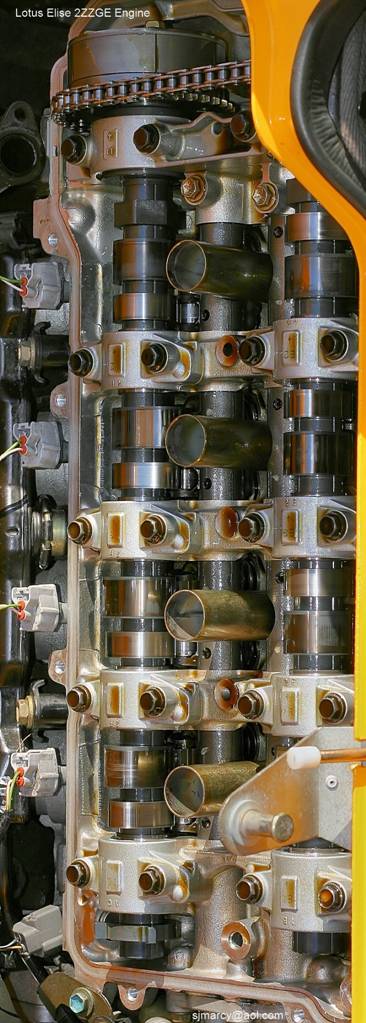

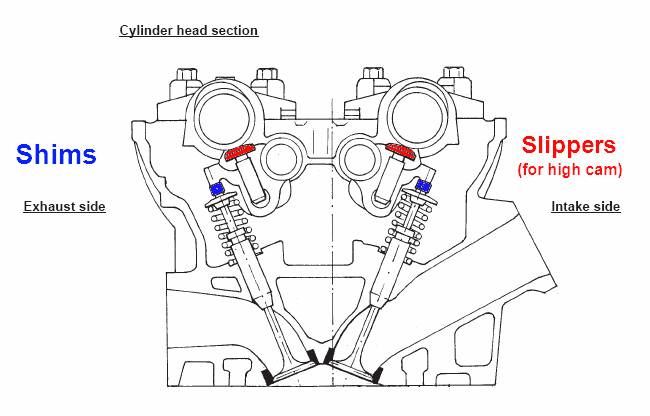

Our motor uses the

lightweight shim under tappet approach. Little lash caps on top of the valve

stems. The roller and slipper are height matched such that both clearances are

set when the tip clearance is set. The wear is low,

it's a PITA to set as the cams have to come out. But especially if you'll have

the cams out reset it all. You check clearances with everything together,

writing it all down. Then you disassemble the works and measure the shims,

calculating what is needed. After doing any needed, you reassemble and confirm

clearances. Some cars use pop out disc shaped shims weighing about an ounce

apiece...which are much easer to service...but those weighty shims and their

buckets affect high rev operation and required spring rates.

“Why are they called lift bolts?”

They are commonly known as

lift bolts by the Celica guys.

I've run mostly Mobil 1

0W40 oil, first in the API SM version, and subsequently in the latest SL

version. Both API specs have reduced ZDDP compared to prior specifications. It

also appears that some of the Mobil 1 weights are fully synthetic only in the

legal sense. Now I'm running Mobil's (legal and actual 100% synth)

Delvac 1 5W40 API SL for now along with a Mobil 1

#209 (larger than stock) oil filter Delvac 1 has much

more of the proven cam protecting elements in it. This may be healthier for our

high cam and slipper along with parts of the cam switchover mechanism.

Here is a TSB writeup about them...a how-to in case one snaps:

http://teamcelica.com/tech/installs/liftbolts/liftbolts.pdf

If I had to do this I'd

yank both cams and reset the shims to perfection based on a hot engine

clearance. It's much easier to just change out the bolts from time to time.

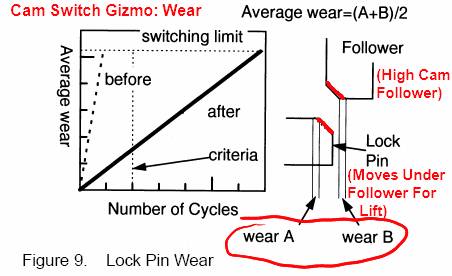

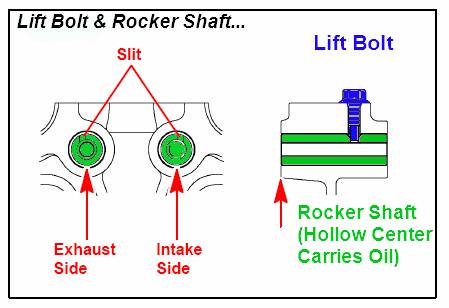

“What Causes the

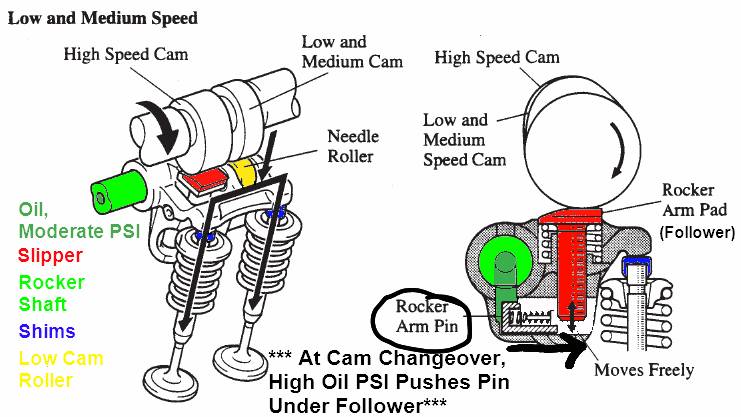

When you hit 6200 RPMs, a solenoid valve (near the oil filler cap end of the head)

opens. This sends high pressure oil down both rocker shafts. The high oil

pressure overcomes the spring holding the Rocker Arm Pin in the low lift

position. The pin is forced under the slipper follower which activates the high

cam. While on the low cam, the high cam's Slipper Follower

pulses up and down, following the high cam profile but producing no useful

action.

There are 8 of these

rockers to be switched over. Each rocker handles a pair of valves. The tip of

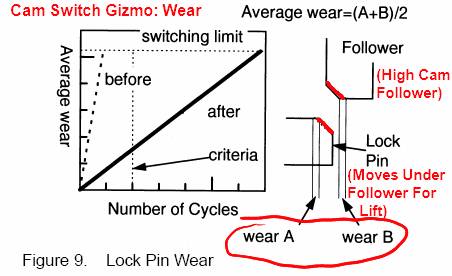

the Rocker Pin and and bottom of the Slipper Follower

experience switchover wear as previously noted and diagramed a few posts up...

I'd guess they'd prefer EP oil additives...

“Improving the Lift Bolts”

Here are some closeups of the

Our lift bolts wear in the

place shown. When they break, the troublesome failures tend to occur in the

area of the nearby threads. I am unaware of any Lotus failures,

the Celica crowd has experienced failures over time.

The tweaked bolt benefitted

from about 2 minutes of 1000 grit hand sanding: note the improved surface

finish. This would favorably affect wear factors. A further tweak, not shown,

is to polish the first few threads. The roots of the thread are the area to

concentrate on - use a dremel to polish down there.

This would double or triple fatigue failure life by reducing stress risers which

lead to the PITA breaks in that area. As you can see the surface finish of the

threads and wear area is not so hot. Of course this IS a 49 cent part with a

reasonable lfe span, ha!

I think that a polished,

latest design/build lift bolt would be a better tweak than cryo

treatment if one wished to do so. Since friction and fatigue life factors are

both inherently improved by the better surface finish. The latest silver bolts

seem better than the gold colored bolts the engine came with. I'd have to research

the oil flow through that area but it could turn out that a dab of cam assembly

lube with EP additives could remain in place long enough locally to assist with

lift bolt break-in.