My BMW 335i RIX Effects Boost Gauge

Installation

I originally purchased the

first solution RIX Effects brought to

market in the form of a pod that wedged in the corner of the

dash/windshield/pillar with a VEI gauge but was not satisfied with it and

returned it- I was looking for a more integrated solution. Rick came out with

his idea for a more integrated approach a short while later, it replaced the

driver’s side vent with a gauge that perfectly matched the BMW OE lighting and

looked OE.

To see what the VEI gauge looks/works like, you can see Pikka’s

video with RIX’s original solution here:

http://www.youtube.com/watch?v=b1z397UaABQ

.

The vent gauge works similarly but has a few new things for RIX such as JB3 map

switching.

I offered to evaluate one of

the first units shipped and decided to take some pics of my installation, Please note that these might be used to

supplement the RIX Effects

instructions that came with your gauge but should not replace them. Details in

the instructions were NOT replicated here so please refer to the RIX

instructions.

I did things in a slightly

different order, I started by removing the vent assembly- it is press fit and

can be removed by hand with no tools, just pull it straight out.

I sat the vent assembly to the

side and removed the shifter pieces to run the wiring. I removed the shift knob

(pull up hard), the shift boot (four clips, removed by tugging upward gently at

clip areas), and the foam insert around the shifter:

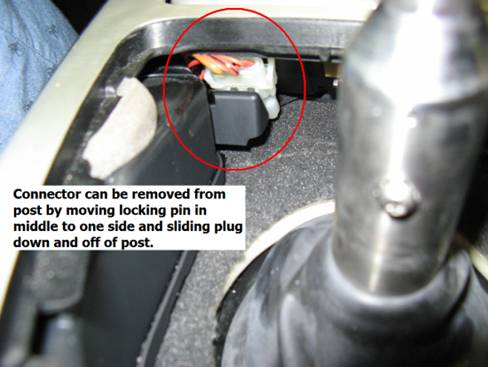

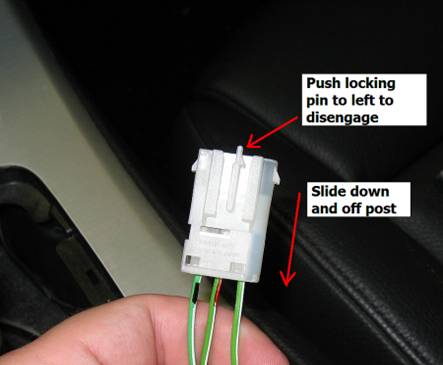

With all of the shifter pieces out

of the way, I had enough room to access the plug for the ashtray. RIX has

provided a plug-and-play solution for the wiring harness. The OE ashtray plug

is held to a post in the console and can be removed by releasing the clip in

the center of the plug. The plug can be removed from the socket by pushing the

release tabs on either side while pulling apart. The wiring harness is then

plugged in. Once the gauge wiring harness is plugged in, the plug can be reattached

to the post by sliding it up until it clicks in place, the wiring can be tucked

forward and out of the way. I ran the gauge end of the harness between the

carpet and console and fished it out, it can then be

tucked along the console edge up to the lower dash trim piece:

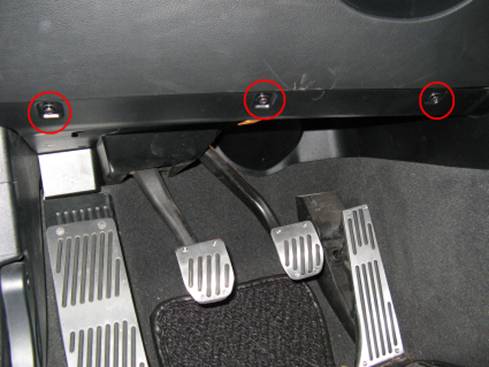

Three Torx screws for under dash

cover are removed, cover can be pulled back and left

to hang for access to run wire harness and vacuum line:

I tucked the wire in under the edge of

the console and ran it across the lower dash and up to the left of the vent

cavity. I was careful not to pinch the harness or make contact with screws when

re-installing the lower dash cover.

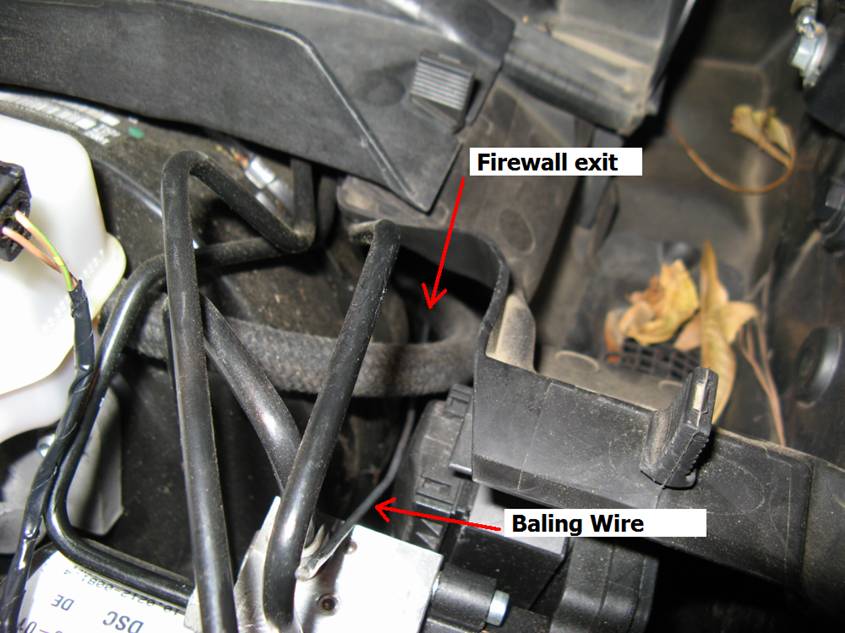

I then ran the vacuum line. I found

some baling wire, slid the vacuum line over the baling wire and then used

electrical tape to make sure it would not separate. I found a fabric covered

hose about ½” in diameter that looked like a good place to run the line, almost

directly behind the clutch pedal, and carefully pushed the wire through the

grommet surrounding it (a deviation from the RIX instructions). I found it on

the other side, by the brake reservoir (cover removed) and pulled it through:

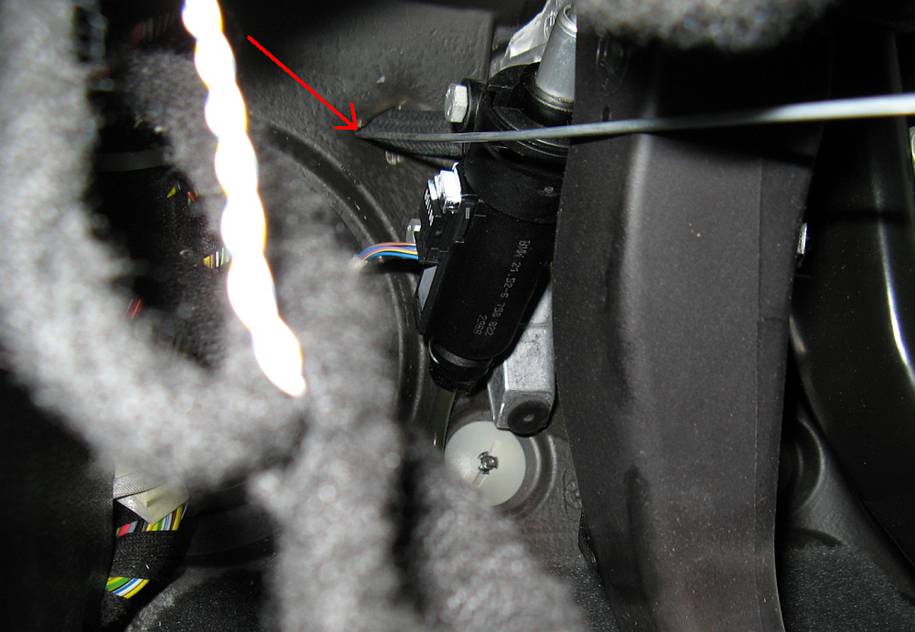

Wire was then run through an

existing grommet and down under the diverter valves and to the diverter valve

vacuum line junction. I put a slightly larger and harder piece of vacuum line

around the main one to guard against abrasion from the grommet down. I also zip

tied the rubber hose at the vacuum line and wrapped it with cloth based

electrical tape. When tucked under the DVs (making

sure not to kink any of the lines), you would never know there was a boost

gauge hooked up:

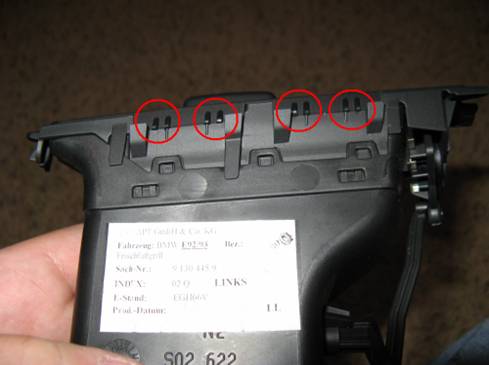

Now, time to disassemble the vent

and get the gauge ready to connect. The vent is removed from the trim piece by

carefully unsnapping at four points shown (I used a small flat blade

screwdriver), applying some pressure to release the clips on bottom, and

sliding to the side to disengage:

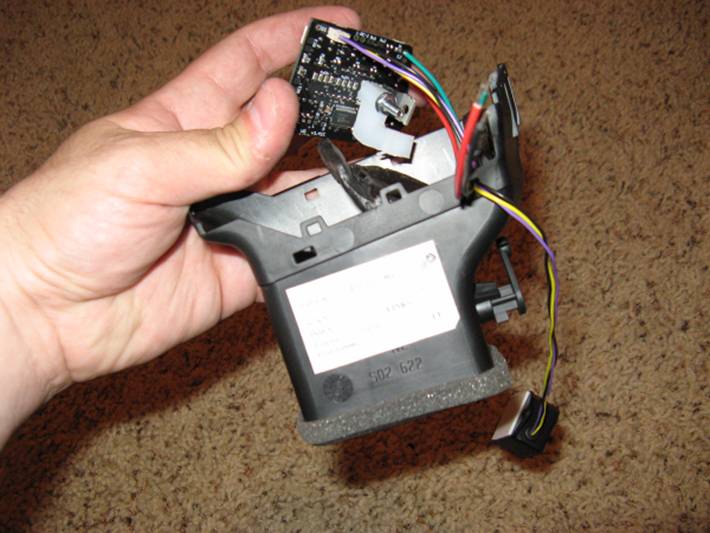

Now that

the vent is removed from the trim piece, the disassembly can begin. I unsnapped

the vent door control arm from the socket carefully. While applying slight

pressure the clips on top and bottom are unsnapped, the piece will then tilt

and allow the clip on the side to be undone:

The horizontal louvers are removed from the vent by

unsnapping at two points on either side:

The

vertical louvers are removed by flexing the vent and popping the four snap-in

points out, two on bottom and two on top:

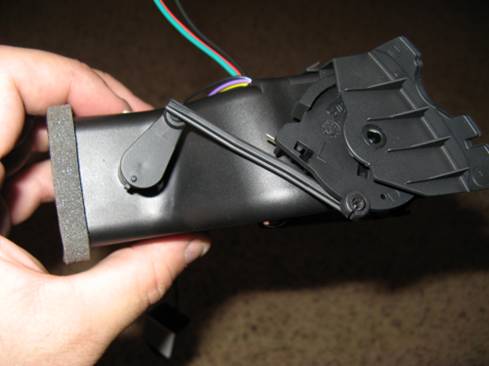

The vacuum

sensor plug is routed through the no-longer-used vent hole and plugged into the

gauge, the gauge wiring is routed through the same

hole:

The gauge

is put in place after installing the foam guard in the empty vent assembly and

the mounting screw is started (NOT tightened) ……and the reassembly starts. It

is a little tricky, you have to hook the bottom of the vent cover on the bottom

and carefully maneuver the smoked gauge face into place before snapping it back

together. Once together, the gauge is mounted as per RIX instructions with a

single screw, tightened while applying pressure to the smoked face. I found

that if too tight, the direction of tightening force would twist the gauge and

cause the switch to bind. The vent door control arm can be snapped back into

the socket and the vent assembly can be reinstalled on to dash trim piece:

Back to the

car to hook up the vacuum lines and wiring harness. I did not use the double

sided tape for the vacuum sensor but wrapped it with some packing foam and tucked

it down beside the vent area. Be careful when routing the wiring that it is not

in the way of the vent door control arm. Wiring harness is color coded, plug in

like wires and tighten screws to lock in place. Installation is reverse of

removal:

Finished

product looks great, kudos to RIX Effects for bringing such an integrated

solution to market: