My Lotus Elise ForcedFed Header Installation (Bill Henderson, 01-06-07)

![]() Standard Disclaimer: The following is my experience

provided for informational purposes only, any use of this information by other

parties to conduct installation is at their own risk, no

warranty/guarantee that information is accurate is expressed or implied.

Standard Disclaimer: The following is my experience

provided for informational purposes only, any use of this information by other

parties to conduct installation is at their own risk, no

warranty/guarantee that information is accurate is expressed or implied.

Tools Used:

- Rhino

Ramps

- Low-profile

Jack

- Small

Head Ratchet (Husky Pro), Socket Handle, and Breaker Bar

- Swivel

Extension

- Metric

Sockets

- External

Torx Sockets

- Metric

Wrenches (GearWrench preferred)

- Adjustable

Wrench

- Needle-nose

Pliers

- Rubber

Mallet – useful for aligning exhaust

Time: 4-5

hours dependent on skill level

Steps prior to ramps: There are a few things I did prior to getting the

car on the ramps. First I jacked up the car on the passenger side and removed

the rear wheel and wheel liner (5 plastic screws); this provided access to the

air injection tube. Using needle nose pliers I removed the clamp for the cap on

the end, and then pulled the rubber hose off:

Next, I removed the bolt

holding the tube to the motor using a ratchet and a swivel extension:

The wheel and wheel liner

were reinstalled and the jack was moved to the driver side and that wheel was

removed for access to the post cat O2 sensor. The O2 sensor was removed and

left hanging:

The trunk was opened and I

removed the upper exhaust manifold heat shield bolts (2) on top:

Steps after the car is on ramps: The car was then backed on to a set of Rhino Ramps

for lower access. The diffuser panel was removed (3 bolts on each side, 5 bolts

under the license plate, 2 large bolts towards the front of the car, and 5

small bolts where the diffuser joins the other lower plate:

After the diffuser was

removed the exhaust clamp was loosened, and the passenger side exhaust mount

hanger bolts were removed so that the exhaust could be removed:

The driver side exhaust

hanger bolts were loosened a little (but not removed) and the exhaust was

carefully dropped under the car to the ground and moved to the side:

The next item to be removed

was the pre-cat O2 sensor, once removed it was left hanging:

The catalytic converter can

now be removed by removing the 2 spring tension bolts that hold it to the

exhaust manifold (the riveted heat shield was not removed for use with the new

header). The upper heat shield lower bolts (2) were also removed as seen in

first picture below:

The lower

engine/transmission mount heat shield is now accessible, 2 bolts hold it to the

frame:

The lower exhaust manifold

mount can be removed, one bolt on the manifold and two bolts on the engine

block:

The upper exhaust manifold

heat shield is removed, kind of like a puzzle - be patient, it will come out in

the right position without bending or cutting:

Next, the lower exhaust

manifold heat shield bolts (4) and heat shield were

removed. This one was a little tougher than the upper heat shield as there was

not a lot of room to maneuver but as above, treat it like a puzzle and be patient, it will come out:

Only thing remaining is the

exhaust manifold bolts/nuts: Two Torx head studs with nuts on either top side, one bolt top middle, and two lower bolts.

Using a combination of ratchets, socket handles, and bars all of these can be

removed. By first loosening the nuts on the Torx head studs, the tension is

removed and then the Torx socket/ratchet can be used to remove the studs. This

is necessary to provide clearance to remove the exhaust manifold with the air

injection pipe intact. NOTE: The Torx socket used is a size E8:

The exhaust manifold is

removed from the bottom of the car, it may take a few tries to get it in the

right position to work the air injection pipe out between the tensioner and engine but it is possible. Compared to the

new header, the welds in the collector are noticeably cleaner and the pipe size

is larger:

The Torx head studs are

reinstalled:

The old exhaust manifold

gasket was removed and a new one installed. This gasket is a crush gasket and

it is good insurance to replace now, it only cost $20 at the Toyota Dealer, P/N

17173-88601. This gasket was reinstalled the same way the original was, with

the arrow in the center pointing towards the passenger side:

The header can now be

installed, there is even less room to work than there was before. The top nuts

and bolts can be accessed with a torque wrench (spec is 37 ft-lbs); the bottom

could not so I tightened those by feel with a small ratchet. The exhaust

manifold heat shields are NOT reinstalled:

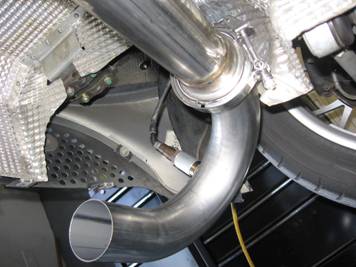

The test-pipe or high flow cat

is attached to the header with three springs, I found it easiest to hook 2

springs while the pipe was at a 90 degree angle to the header and then to

stretch the pipe into place, this only left one spring to wrestle with pliers

to get in place. The post-cat U-pipe was installed with supplied clamp and the

O2 sensors were reinstalled as well. I used the GPMoto

CEL fix which extends the post-cat O2 sensor away from exhaust flow to prevent

the Check-Engine Light (CEL) from coming on due to a test pipe or high flow cat

install (see note UPDATE at end of article for this CEL fix issue):

The exhaust reinstalled

(exhaust clamp and hanger bolts/hardware) along with the lower

transmission/engine mount heat shield:

I test fit the diffuser and

used a rubber mallet to position the exhaust within the diffuser cutout before

tightening the clamps. After making sure the clamps were tight and everything

lined up, the diffuser was reinstalled and the car was left to idle for 15

minutes to give the ECU a chance to adjust to the new header.

Time for a drive to see if

all the work paid off (may not want to be too hard on the car for some miles as

it may run a little lean until the ECU has some time to adjust the fuel

maps)…….. ![]()

![]()

[UPDATE] The GP Moto CEL fix did not work (error

"P0420- Catalyst System Efficiency Below

Threshold" every 50 miles) but I have found a few options:

1)

I have found another mechanical CEL fix (different

design) that has worked for the past 300 miles and no CEL, available on eBay

from seller strutking. It is a much lower cost option

than the first one I tried and works much better. I did have to drill some for

additional depth but communicated this to the seller and he has told me that in

the future he will make them a little deeper (about ¼” deeper than other

applications). GP Moto on left, strutking on right:

2)

Other people have had de-cat success with the Mini

version of this electronic O2 simulator from www.o2sim.com

: