Mirrored from: http://www.4x4xplor.com/trannyservice.html

Jeep AX-15

& NV3550

Transmission

NP231

Transfer Case

Fluid Change

Maintenance Service

Changing

your Jeep's transmission and transfer case fluid should be done as part of your

routine 30,000 mile tune-up service and/or after doing a deep water crossing.

This write-up covers what you will need and how to perform this very easy

maintenance service on an AX-15 or NV3550 transmission and an NP231 Transfer

Case. All three are typically found in a Jeep TJ Wrangler, YJ Wrangler and XJ

Cherokee.

AX-15 Transmission Service

1. Make

sure you have everything you need before you get started. There's nothing worse

than draining your transmission only to find that you need to make a run to the

parts store. On an AX-15, you will need 4 quarts of transmission fluid, a

ratchet, 19mm socket, an oil catch pan and a bottle pump.

2. Park on level ground and place an oil catch pan

underneath your transmission. Using a 24mm socket, remove the AX-15

transmission fill bolt which is located on the driver side of your Jeep.

3. Located

on the passenger side of your Jeep, remove the AX-15 transmission drain bolt

using a 24mm socket and do so slowly so you do not to drop it in the oil catch

pan.

4. The

transmission will drain quickly and forcefully so make sure you are out of the

way and that the pan is in place to catch the fluid.

5. The

drain bolt of the AX-15 transmission is magnetized to collect bits of metal.

Inspect this for unusually large bits of metal, clean it and then reinstall it.

Tighten bolt to 14-20 ft. lbs. of torque.

6. Open up a bottle of transmission fluid, attach your

bottle pump to it, insert the hose into the fill hole and start pumping away.

Keep pumping in fluid until it begins to ooze out the fill hole and then reinstall

the fill bolt. Tighten this bolt to 14-20 ft. lbs. of torque.

NV3550 Transmission Service

1. Park on level ground and place an oil catch

pan underneath your transmission. If you have an oil pan skid plate like me, you will first

need to completely remove it before you can continue.

2. Place an oil catch pan underneath your transmission.

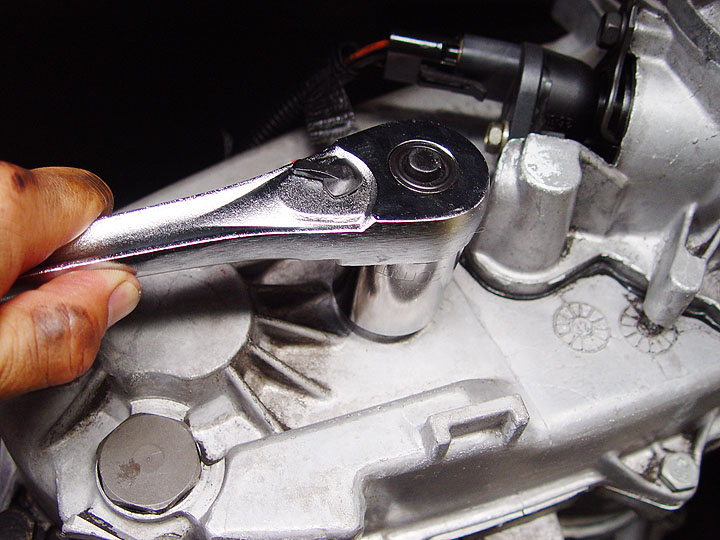

Using a 17mm Allen Bit, remove your NV3550 transmission fill bolt which is

located on the driver side of your Jeep. Then, slowly remove the drain bolt

using the same 17mm bit so you do not to drop it in the oil catch pan. The

transmission will drain quickly and forcefully make sure you are out from under

it.

3. The inside end of your drain bolt has a small magnetic

tip which is used to collect fine metal filings. Clean off this magnet and take

some time to inspect the pieces carefully. Fine particles will stand up like

hair and this is normal, big chunks are NOT.

4. Once drained, re-install your drain bolt making sure to

torque it to factory specifications. My 2000 FSM has 14-20 ft. lbs. indicated

as the proper torque setting.

5. Now it time to refill your NV3550 Transmission. Open up

your bottle of Mopar Transmission Fluid, attach your bottle pump to it, insert

the hose into the fill hole on your transmission and start pumping. You will

need about 2 bottles to fill it up and keep pumping it in until it starts to

ooze out of the fill hole. Be sure to do this on level ground or else you may

not put in the proper amount.

6. Keep filling the transmission until fluid starts to ooze

out, re-install the fill bolt and be sure to torque it down to 14-20 ft. lbs.

like the drain bolt.

NP231 Transfer Case Service

On a TJ,

there is a proper way to service your NP231 transfer case and a lazy way. On an

XJ, you do not need to worry about this as there is no transfer case skid plate

in your way to deal with.

The proper way

(lazy way follows this):

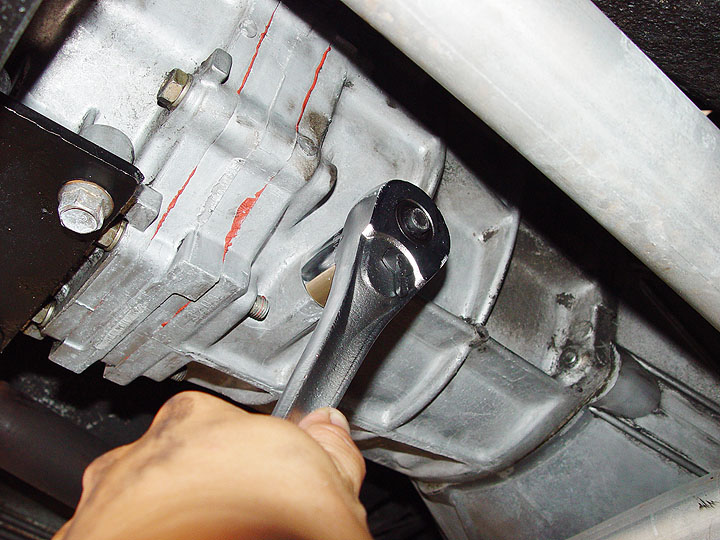

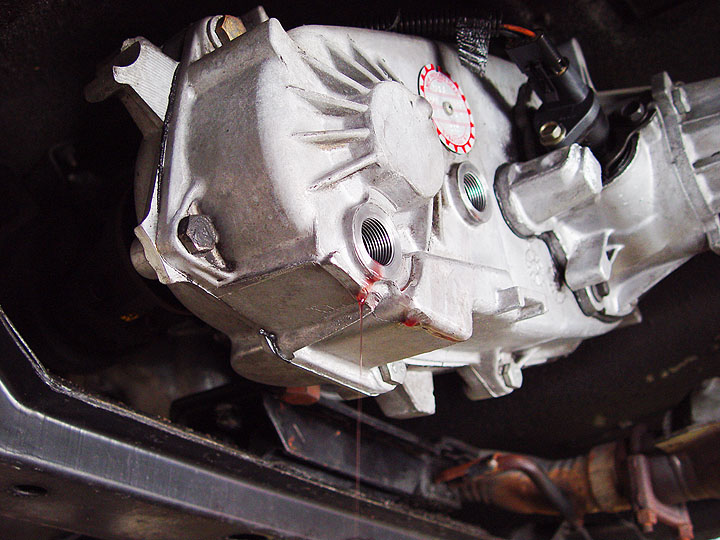

This is what your NP231 Transfer Case looks like

(shown on a TJ) from under the back of your Jeep. I have indicated where the

fill and drain bolts are located in the pic to the left. Please note that some

NP231's have different types of bolts used here.

1. On a TJ, you will need to remove the transfer case skid

plate to service the NP231 Transfer Case. To do this, remove the 4 nuts

securing your transmission mount to the transfer case skid plate using a

1/2" socket.

2. Place

a jack stand underneath the bell housing of your transmission. Then, using a

floor jack with a piece of 2x4 on top of it to help distribute the load, lift

the center of your transfer case skid plate up until it puts a little pressure

on it.

3. Remove

the 6 bolts securing your transfer case skid plate to your Jeep's frame rails.

On a 1997-2002 Jeep TJ, you will need a 3/4" socket. 2003+ TJ's use a

metric bolt that is similar in size but I do not know what it is. A breaker bar

will come in handy here and if you live in the rust belt of America, some PB

Blaster on the bolts will help out a lot.

4. With

the bolts removed, slowly lower your floor jack just a little and make sure

that your transmission bell housing is now resting on top of the jack stand. Then,

grab the lip of the transfer case skid plate and roll the whole thing out from

under your Jeep. Set your skid plate aside for now.

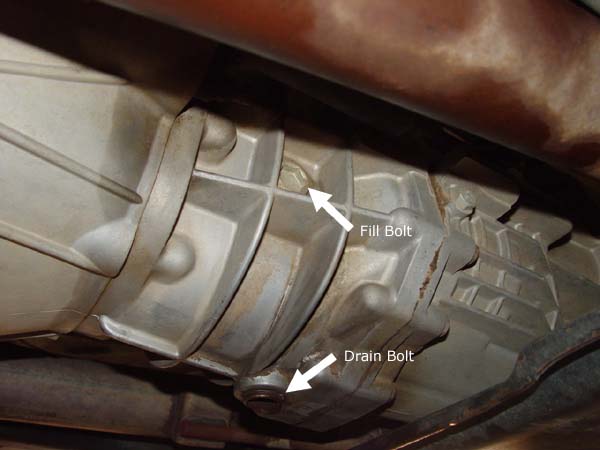

5. As

I mentioned before, I have seen the NP231 Transfer Case come with 2 different

types of fill and drain plugs. One requires a 30mm socket to remove and the

other uses a 10mm Allen bit. Determine which you will need and remove the fill

bolt.

6. Place

an oil catch pan under your transfer case and then remove the lower drain bolt

again using the same 30mm socket or 10mm Allen bit that you used for the fill

bolt.

7. Allow

your NP231 Transfer Case to drain completely before proceeding.

8. Once

drained, re-install the drain plug and tighten it to 15-25 ft. lbs. of torque.

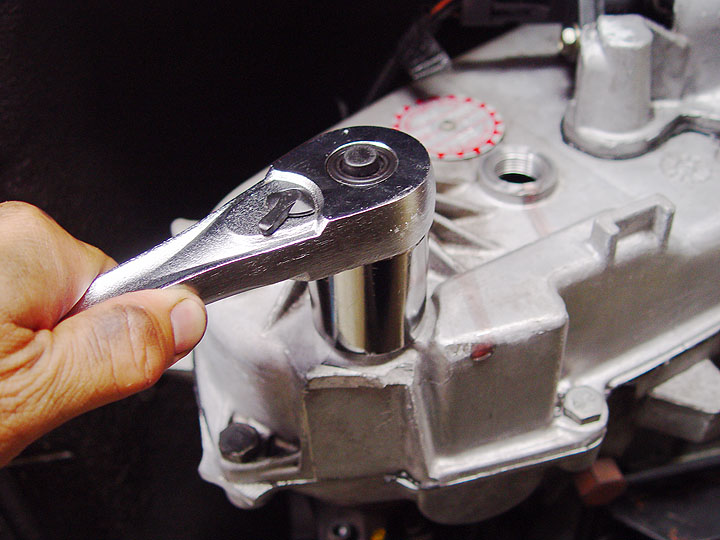

9. Using

a yorker spout on the bottle or a bottle pump to

assist you, fill up your transfer case with ATF+3 until it begins to ooze out

of the fill hole and then re-install the fill bolt making sure to tighten it

down to 15-25 ft. lbs. of torque. (Photo as shown on an XJ)

10. Put

your transfer case skid plate back on top of your floor jack and stabilize it

by holding it with one hand. Roll it underneath your Jeep and jack it up into

place.

9. Re-install the 6 bolts that hold the

skid to the frame just finger tight so that it can still move around a bit.

Now, re-install the transmission mount nuts. As mentioned, you may need to

shift your skid plate around in order to line up the holes. The transmission

mount nuts will need to be tightened to 40-45 ft. lbs. of torque.

10. Secure the 6 skid plate bolts to

factory bolt to 44-55 ft. lbs. of torque. Remove your jacks, clean up your

mess, re-install your oil pan skid plate and you should be done.

The lazy way:

Just so you all know, the first time I

serviced my Jeep TJ's NP231 transfer case, I did it the proper way as explained

above. However, the second time around, I was pressed for daylight and time and

came up with this method.

Anyway, all you need to do is skip all the

steps involving the removal and installation of your skid plate and just drain

your transfer case directly into it.

Fortunately, the skid plate has a recessed

section directly underneath it with (4) drain hole in it. I just placed an oil

pan directly under these holes to collect the fluid and then wiped down the

skid plate with some rags when finished. Takes a fraction of the time to do.

When finished, please take your used transmission and ATF fluid to your local auto parts store to have it disposed of properly.