Installing Mini Cooper (R50/53)

Springs and Rear Control Arms

The Mini

Cooper S handles great from the factory, but the ride height is a bit too high

for some. Some will argue that putting lowering springs in a Mini will have it

riding on the bump stops and it will handle horribly. What they don’t

understand is that BMW designed the suspension in these cars with progressive

bump stops that are meant to be part of the spring travel to provide a smooth

ride but allow it to handle great as well. I have had no issues and did not

trim the bump stops since that would alter the progressive design intended by

the engineers.

I chose APEX Suspension Systems springs for

their cost (mine were a low-mileage set found even cheaper on the forum

classifieds) and they have turned out to be a great value. Originally intended

as a stop gap for coilovers, I think they work so well that they will become

permanent. I also installed Hotchkis

adjustable rear lower control arms (aka rear camber links) from Way Motor

Works so I could adjust the camber back to spec during the wheel alignment.

This

write-up was helpful to me: http://www.minicooperspeed.com/mini-cooper-strut-springs-or-lowering-spring-installation

Standard

Disclaimer: ANY USE OF THIS INFORMATION BY

YOU IS AT YOUR OWN RISK. I ASSUME NO LIABILITY FOR YOUR USE OF THE BELOW

INFORMATION.

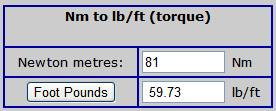

NOTE: TIS Instructions and torque specs at bottom of

write-up for reference.

Front Spring R&R:

First step

is to jack up the front side that you will be working on (using jack stands of

course) and after placing jack stands under the car, removing the wheel/tire:

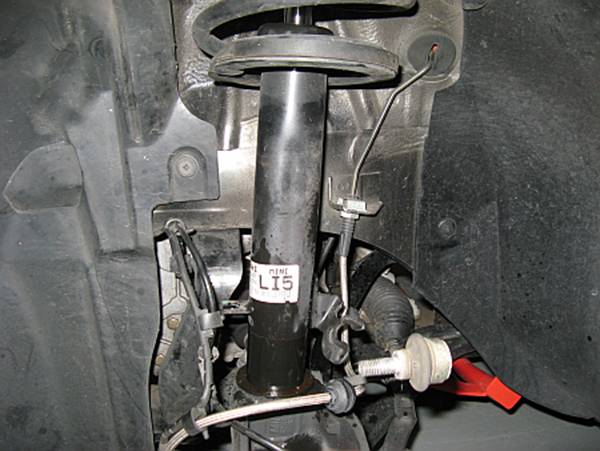

Remove the

brake line and brake sensor wire from the strut retainers carefully:

Remove sway bar end link from

strut: Use a 17mm open

end wrench on the flats behind the sway bar link joint to prevent rotation

while loosening the bolt with a 16mm socket/ratchet. Remove the sway bar link

from the strut mount after removing the bolt:

You may

want to soak the base of the strut to steering knuckle union with PB Blaster so

that it will come apart easily:

Remove the strut pinch bolt: After soaking both ends of the bolt

liberally with PB Blaster and allowing some time for it to soak in, I used an

18mm socket with a ratchet and/or breaker bar to loosen and remove the pinch

bolt. I also used anti-seize with this bolt on reassembly after reading some

nightmare stories on the forums of people breaking these off in the steering

knuckle due to rust-weld.

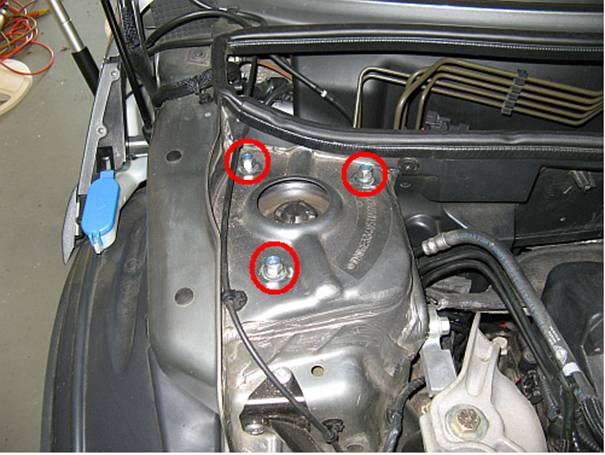

Remove the three upper strut mount nuts:

In my case this required a 13mm socket (OE nuts may be the same….or not):

The

steering knuckle did drop but not enough to free the bottom of the strut- I had

to compress the suspension to remove the strut assembly after removing the

three upper strut mount nuts in order to get enough room to clear the knuckle.

This will require some creative thinking on your part or a spring compressor

that works with the strut installed. It also helps to twist the steering

knuckle while pulling the strut assembly out at an angle:

With the strut removed, the plastic cover can be removed using a standard

screwdriver to access the nut:

Compress

spring using a spring compressor (I have always borrowed one from a McParts store

like AutoZone using their tool loaner program) and remove strut assembly nut:

There are

some different ways to remove the nut from the strut but none work better for

me than an impact wrench, I have air but electric works too. If you don’t have

access to one of these, I have used creative solutions like the one below in

the past- a 13/16 spark plug socket and the correct HEX wrench with Vice Grips,

no guarantees this will work for everyone or every car. Pic below is merely to

illustrate a potential alternative to an air wrench, in the past I would have

cut the hex wrench down so that the Vice Grips and the wrench on the spark plug

socket were closer together, and a closed end wrench on the spark plug socket

will always work better than an adjustable:

After

removing the nut you will see that there is the spring, rubber insulator, top

hat, washer, strut mount, and nut in that order:

When

installing the front spring in the front strut assembly, make sure the spring

ends are positioned at the rubber pad stops and that the rubber pads are

positioned correctly on the lower and upper mounts. Assembly is spring, rubber

insulator, top hat, washer, strut mount, and nut in that order. I found that

the spring compressors were not required to reassemble the strut assembly, but

you may need a helper to start the nut while you compress the spring by hand:

Installation

is reverse of removal J Remember to reinstall brake lines

and brake sensor wiring in strut holders:

Rear Spring R&R:

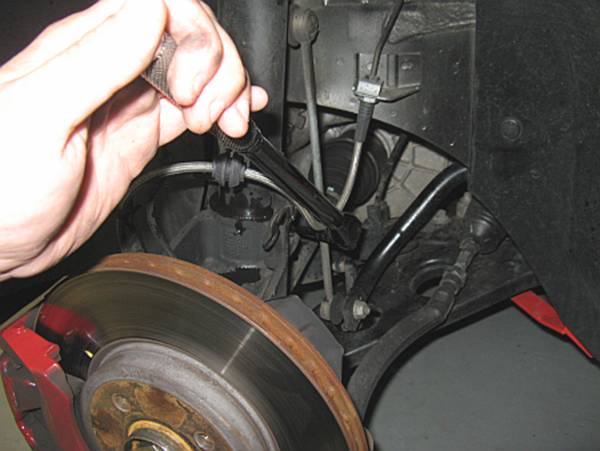

After jacking

and supporting the rear with jack stands, remove the brake line and brake

wiring from the shock holders:

Remove the

lower shock mounting bolt using a 21mm socket with breaker bar at first and

then socket wrench:

Remove the

upper shock mount bolts using a 13mm socket (extension optional):

Disassemble

the rear shock assembly by removing the nut, using an air wrench (16mm socket)

or a 5mm HEX wrench/16mm box end wrench:

Reassemble

the rear shock assembly making sure the spring ends meet the rubber pad stops

and reinstall. Installation is reverse of removal (don’t forget to replace the

brake lines/wiring in the shock holders):

Hotchkis Rear Lower Control

Arm/Camber Link Installation:

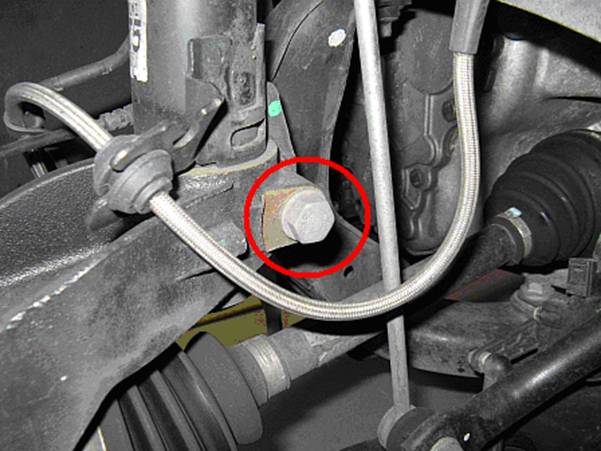

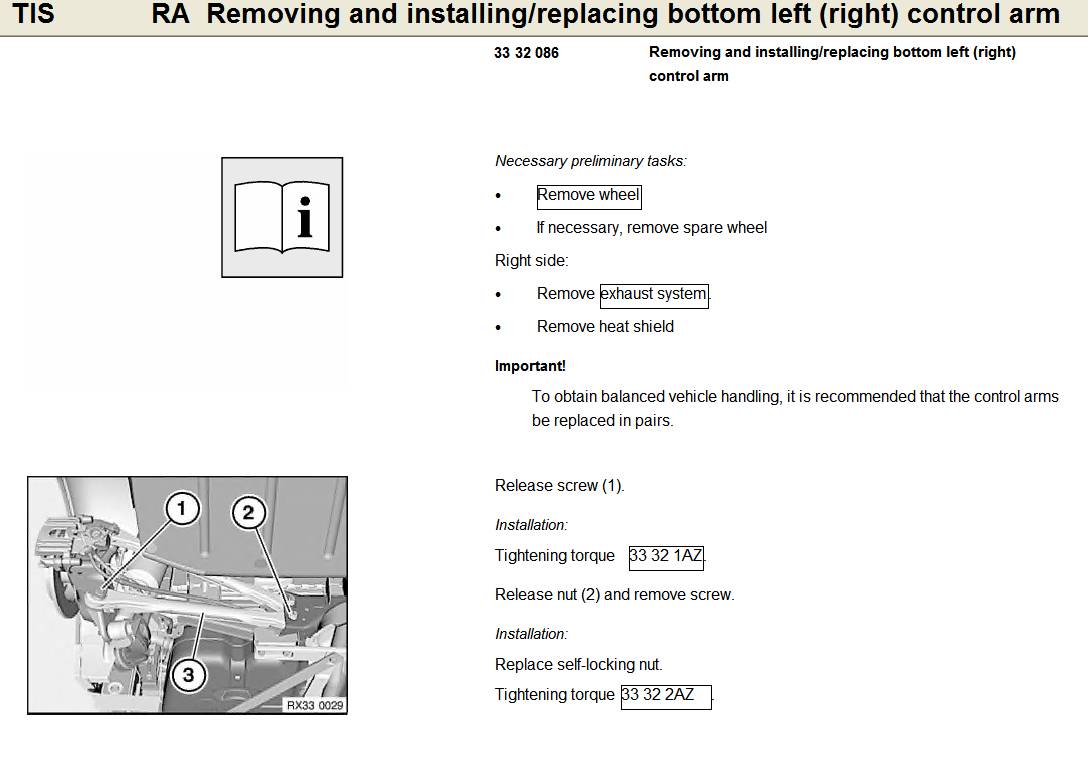

Start by

removing the inside bolt/nut for the lower control arm/camber link. The exhaust

shield may need to be “adjusted” to access the nut:

After

removing the inside bolt/nut, the outside bolt is removed. You can see that

there is some degree of camber adjustment in the factory setup:

After

removing the OE camber link and comparing to the new Hotchkis piece, you can

see that not only will it be adjustable but stronger as well. I adjusted the

new Hotchkis link to be the same length as the OE piece removed, bolt center to

bolt center, to get it close enough to drive to the alignment shop with no

issues. Installation is reverse of removal, I found it easiest to grease the

camber links before installation- Make sure the zerk grease fittings are

pointing down when installed and that the right angle zerk is mounted to the

inside mounting point:

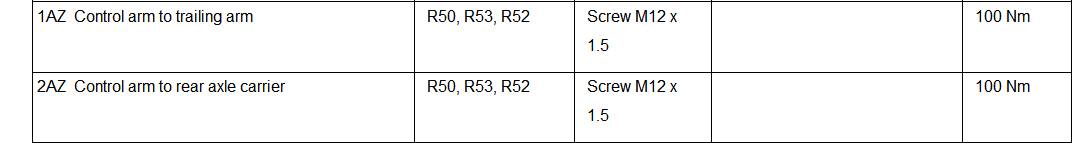

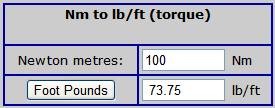

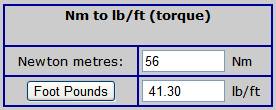

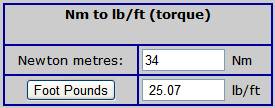

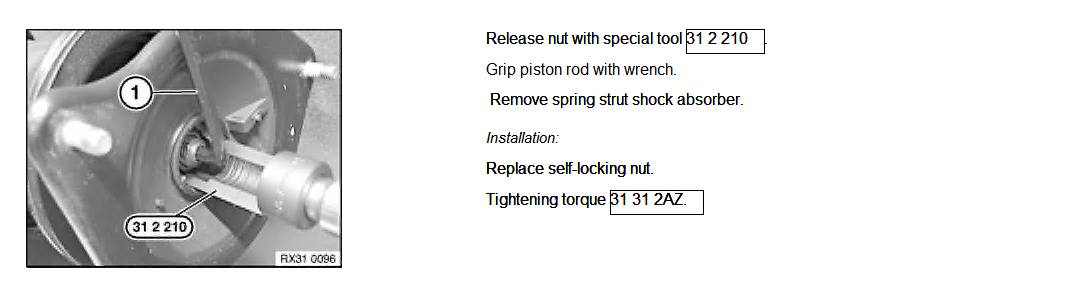

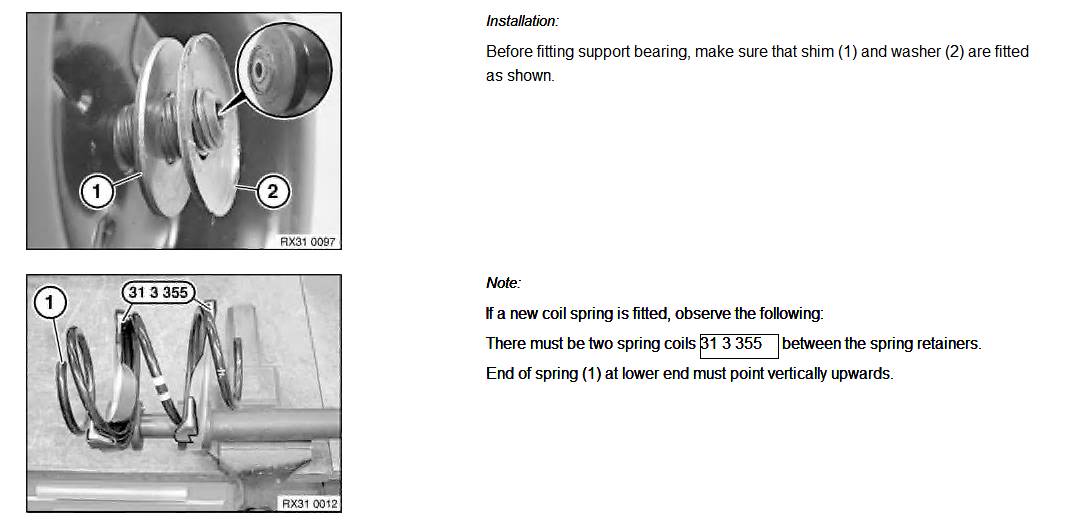

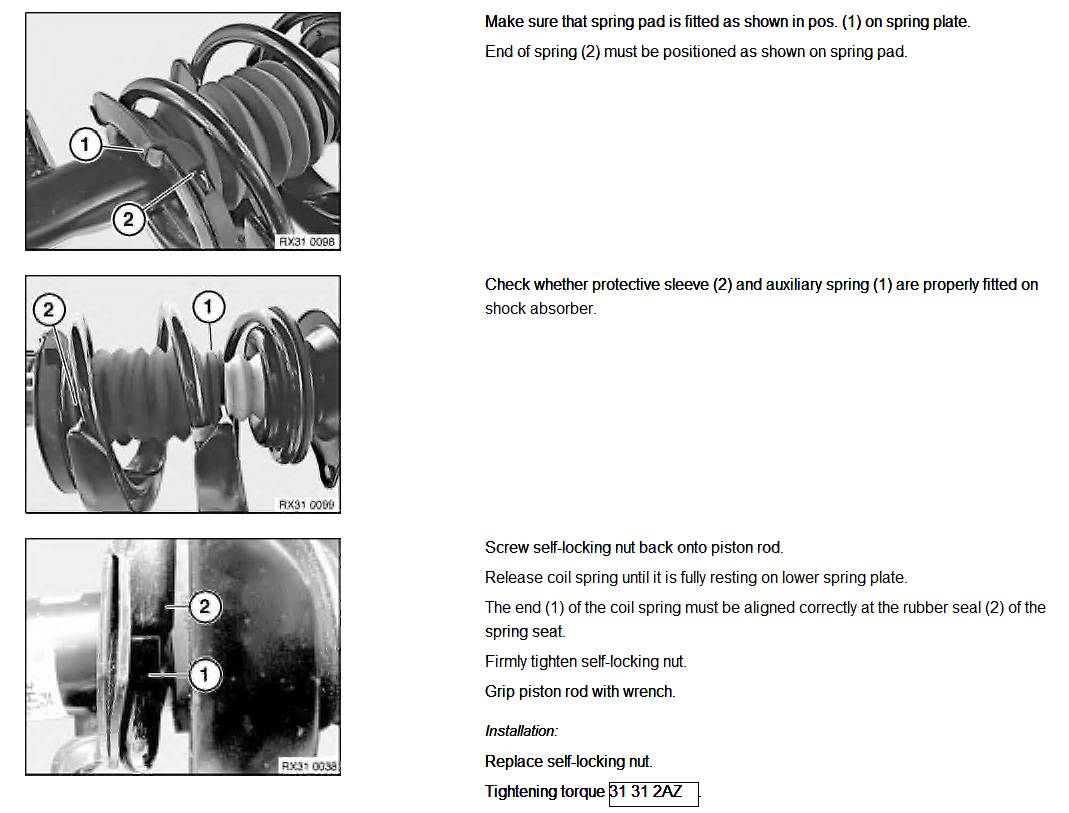

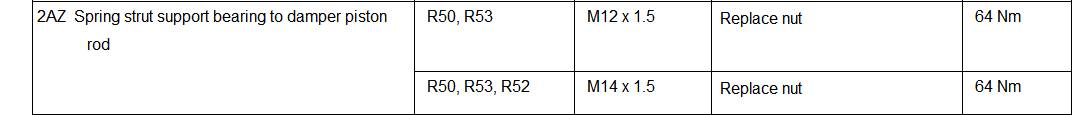

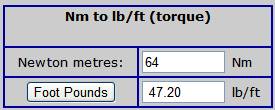

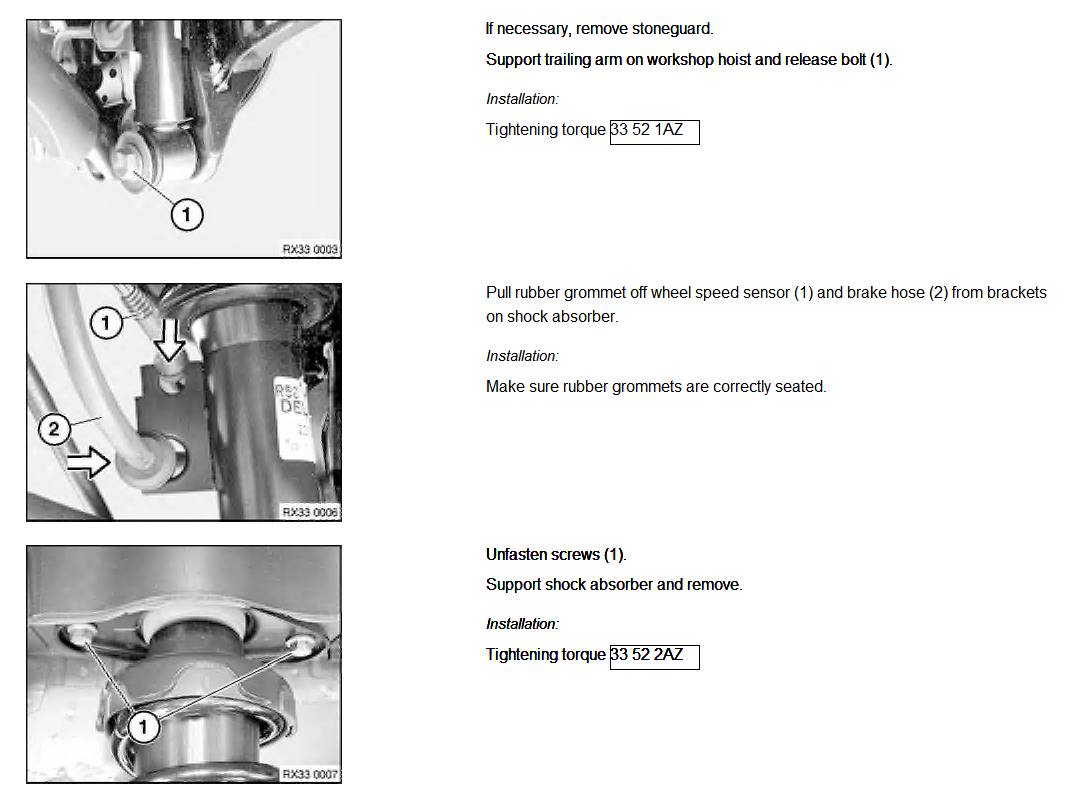

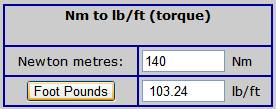

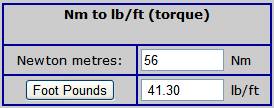

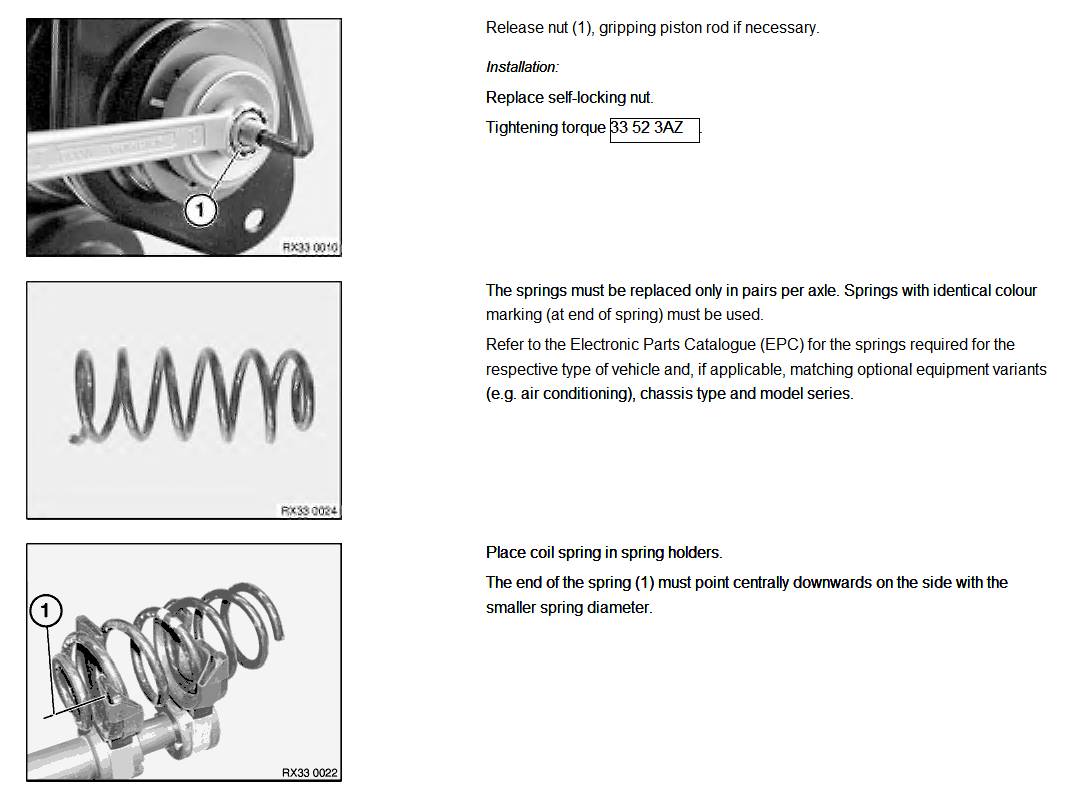

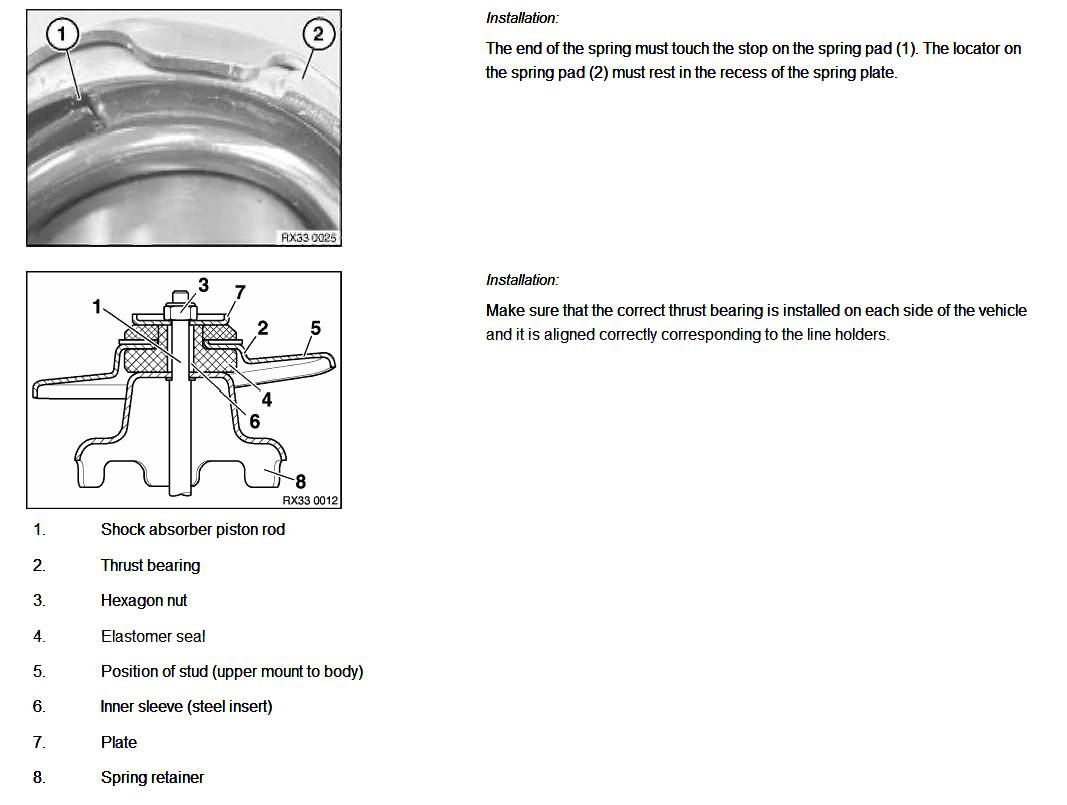

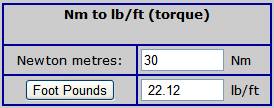

TIS Instructions and Torque Specs:

![]()

![]()

![]()

AFTER COMPRESSING SPRING

WITH SPRING COMPRESSOR

![]()

![]()

![]()

![]()

![]()

![]()

AFTER COMPRESSING SPRING

WITH SPRING COMPRESSOR

![]()

![]()

![]()