Installing MINI Cooper PowerFlex

Gear Box (Transmission)

Bushing Inserts

After some

mixed reviews on the forums I decided to try these out-

they were cheap and fairly easy to install at under $30 and about 1 hour of

time. Some said these bushings caused a LOT more NVH and just to do the upper

and lower engine mounts while others felt they were fine.

Way

Motor Works stocks these and he is a big proponent of PowerFlex

bushings.

I already

had the ![]()

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK. I ASSUME NO LIABILITY FOR YOUR USE OF THE BELOW

INFORMATION.

Installation:

First step

is to get the front of the car up on ramps or jack stands:

The

plastic engine shield will need to be removed so that a jack can be used to support

the transmission; two Phillips screw retainers will need to be released after

removing three bolts up front with a 10mm wrench:

The jack

in the 1st picture above is supporting the transmission (not lifting

it, supporting it- if you see the transmission or car start to lift you have

gone a bit too far). I use a hockey puck to pad the jack:

Use a

small screwdriver to release the clamp by placing in the space and twisting. It

can be re-clamped using large arc-joint pliers. This same type of clamp is also

used with the air intake hose and this process can be used there as well on the

airbox side- no need to remove it from the throttle body:

The

plastic intake tube is removed, it is pulled free from the lower airbox after

the above clamp is undone and the tube removed from the intake scoop:

Remove the

ground wire nut beside the mount- you will need some slack here to remove the

mount:

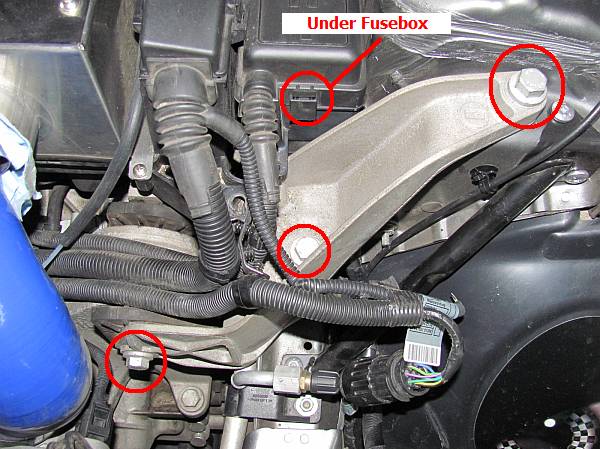

Using a

10mm socket wrench and extension, remove the two bolts holding the fuse box in

place:

Using a 10mm

socket wrench also remove the bolt for the wire harness holder and lower

airbox:

There is a

wiring harness plug and holder next to the mount. You can just unclip the plug

from the holder, I also elected to remove the holder to avoid breaking it and

to provide a bit more room using needle nose pliers to compress the retainer

ears and pull out:

I thought

I might be able to workaround the airbox removal but that was not the case- go

ahead and take it out after disconnecting the battery ground cable. If you need

help with the airbox/ECU removal see my write-up for details http://www.billswebspace.com/MiniR53DDMCAI.htm

:

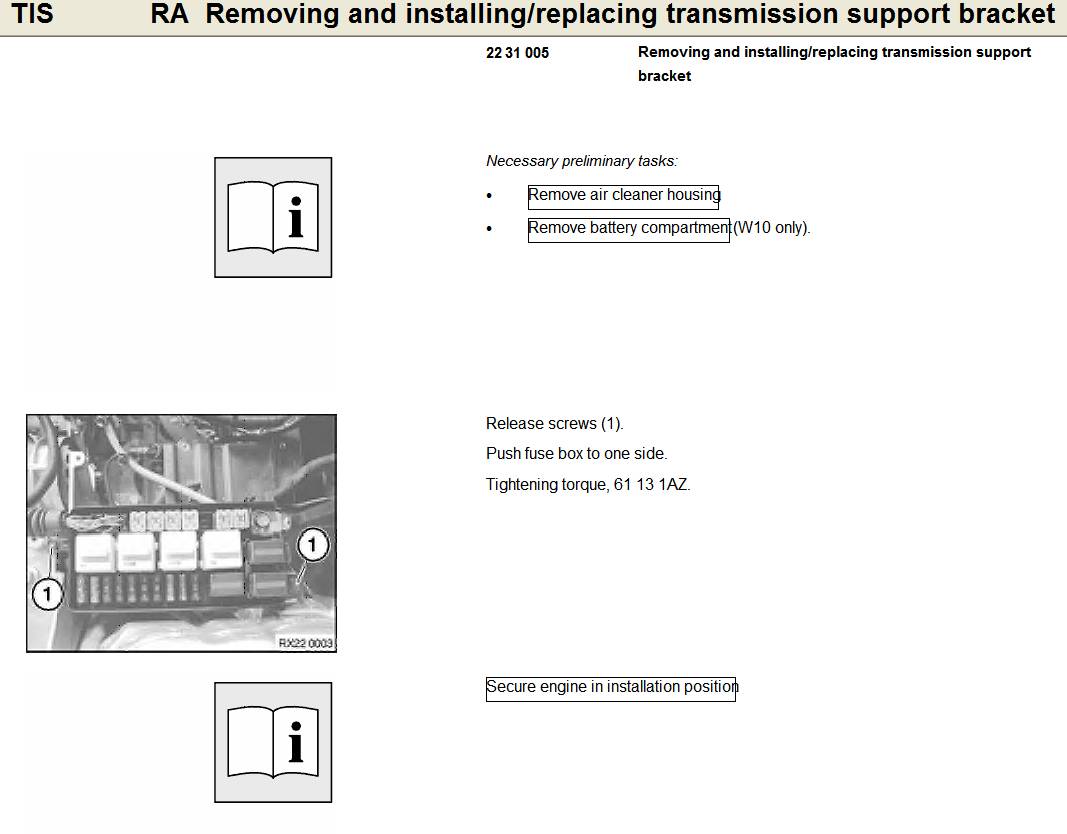

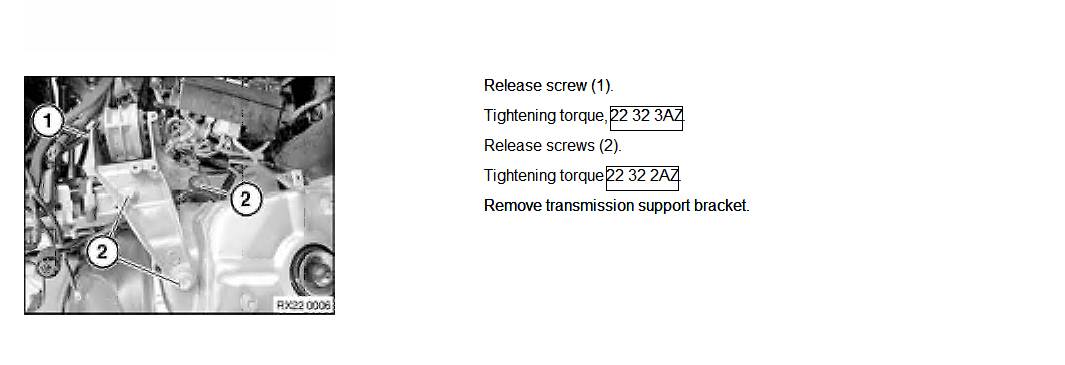

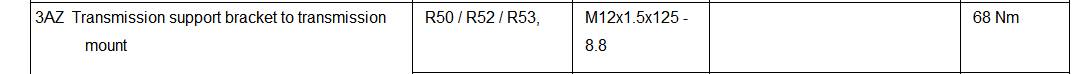

Next up is

the four bolts holding the mount in, removed using a 16mm socket wrench with

extension(s):

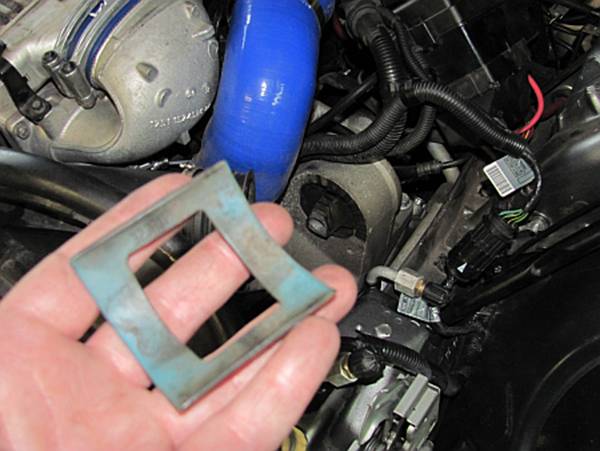

The rubber

inserts are thin and you might have seen that there was some airspace between

the mount and these pieces. Remove them:

There is also

a piece of plastic that need to be removed:

I had read

these inserts were tough to install and since I had some Powerflex lube left

over from past bushing installations (none came with these), I lubed the points

that would be inserted in to the OE bushing:

The

bushings are two different sizes, I put the smaller diameter on at the front

and the larger diameter one at the back:

The mount

is carefully slid back through the wires and over the new bushings- remember

how the wires go and on which side of the mount they belong. Go ahead and start

the bolt for the mount/bushing and run it almost up to the mount, not tight.

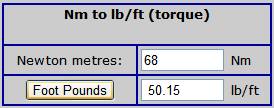

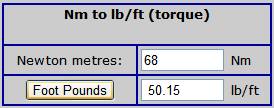

The three remaining mount bolts are loosely installed and tightened to TIS

torque specs (specs at the end of this write-up). You may have to use the jack

to get the transmission and mount positioned just right so all of the bolt

holes line up. All other reassembly is opposite of removal ![]()

![]()

1

2![]()