Installing MINI Cooper PowerFlex Rear Trailing Arm Bushing Inserts

After some

favorable reviews on

Way

Motor Works stocks these bushings and is a big proponent of PowerFlex.

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK. I ASSUME NO LIABILITY FOR YOUR USE OF THE BELOW

INFORMATION.

Installation:

First step

is to jack the car up and remove the wheel, supporting the car with jack

stands:

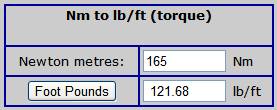

Some only

remove the wheel liner screws up front and hold it out of the way to access the

rear trailing arm mounting point, but it only takes 5 minutes to remove them

all and get the liner out of the way entirely. You will need a Phillips head

screwdriver to remove the plastic rivets and a single screw under the car and a

10mm socket wrench to remove the plastic retainers:

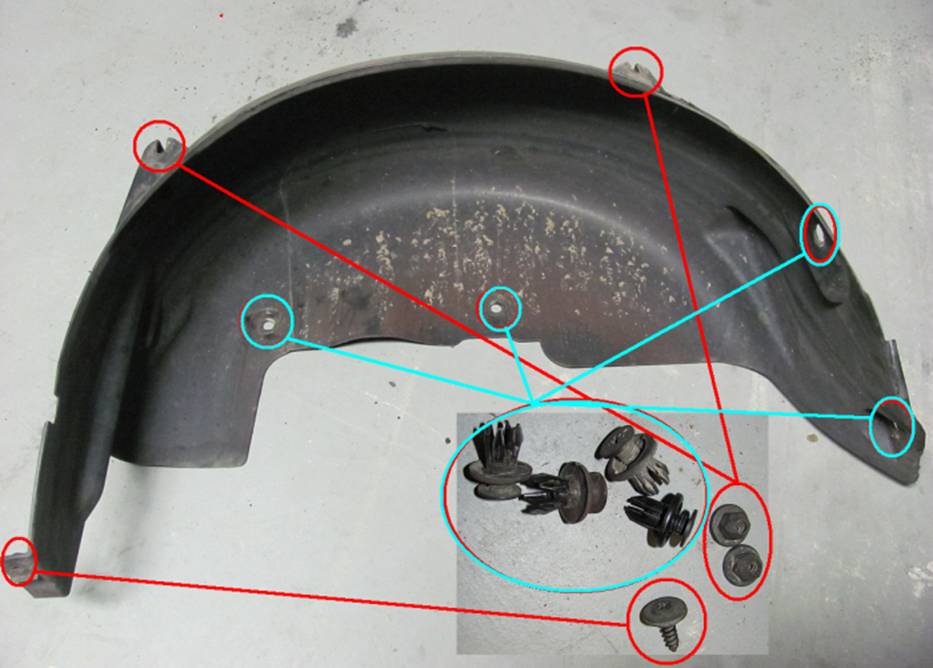

After removing

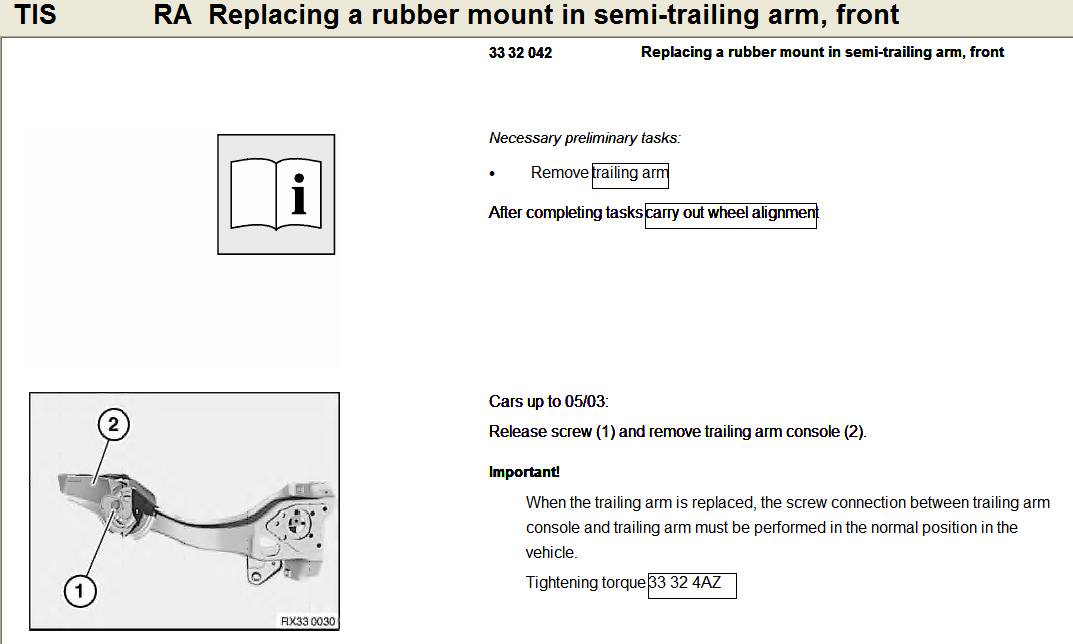

the wheel liner you will see the trailing arm mounting bolt:

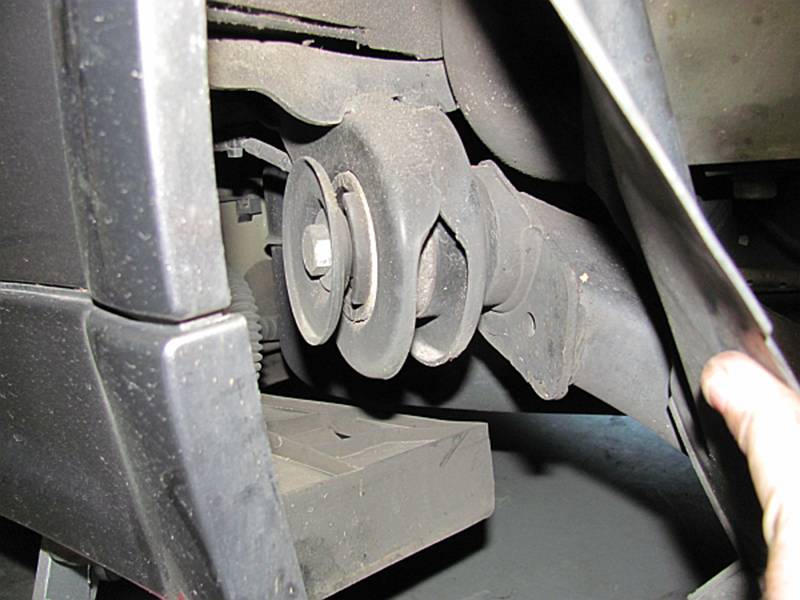

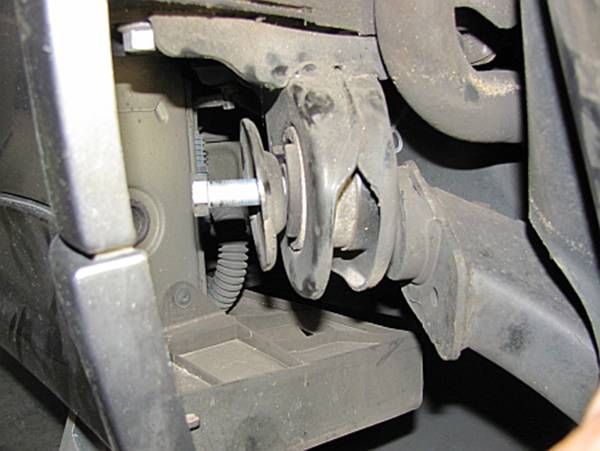

Using a

breaker bar and an 18mm socket, the bolt holding the trailing arm to the

body/bracket is loosened- I used a 3/8 ratchet with an 18mm socket to remove

the bolt entirely once the breaker bar had broken the bolt loose:

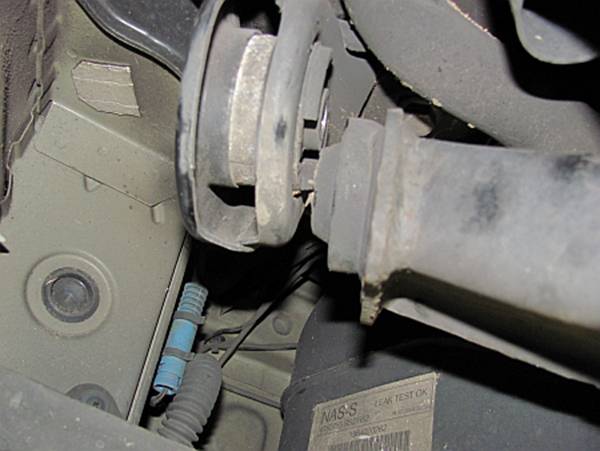

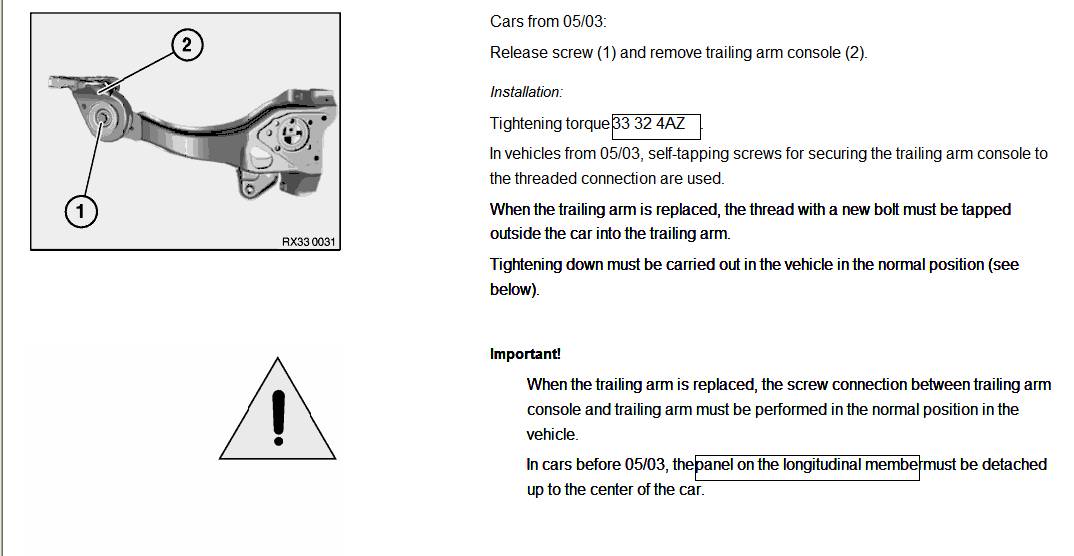

After the

bolt is removed the trailing arm will drop down and is able to be moved by

hand. Now is a good time to remove any dirt from the OE bushing crevices using

compressed air or a damp towel:

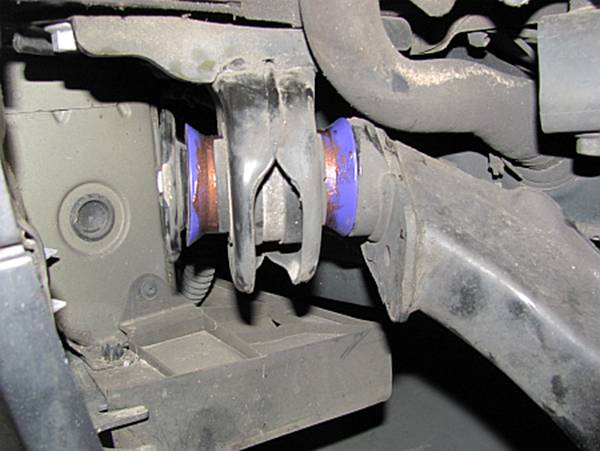

The PowerFlex bushings are lubed up with the supplied lube, I

coated the bushing wherever it would make contact with the OE bushing or

hardware:

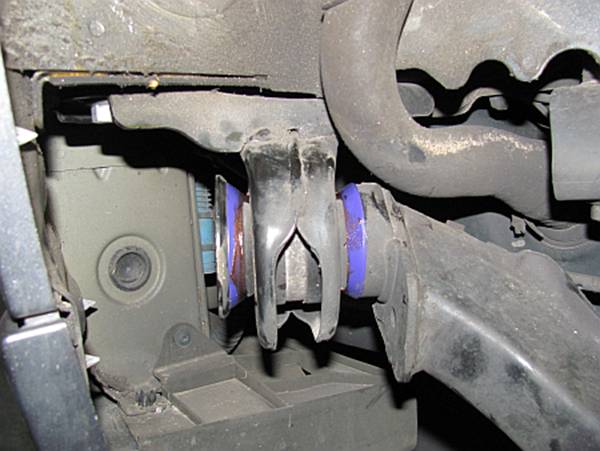

The PF

bushings are inserted into the OE bushing, they will not stay in place very

well until the bolt is started. The trailing arm can be moved by hand to get

the inside bushing in place. The trailing arm can be lifted into place while

your free hand starts the bolt, this can be tricky

while trying to keep the bushings in place so be persistent and be sure NOT to cross

thread the bolt. The bolt can be tightened a bit but the final tightening

should be done with the car at normal height. I used ramps and tightened as

much as I could with the smaller ratchet and then used a torque wrench to

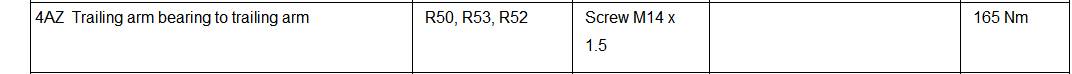

torque the bolt, not a lot of room to move. Torque specs at end of write-up:

![]()