Raising the motor on the Mini

Cooper S (R53) to install:

∑ TSW Upper motor mount

∑ WMW 15% Pulley

∑

∑ Tensioner Damper Poly Bushings

Well, itís

not necessary to raise the motor to install the last two items but they are

easier to get to and why not go ahead and do it all while youíre in there. I

had owned my MCS for about a week before deciding it was time to do some things

right away- I knew the upper motor mount was leaking/failed

when I bought the car and wanted to do the pulley upgrade. While looking at

Wayís online store (Way Motor Works),

I found there were some other items I could/should go ahead and get/install

while doing the others- Work Smarter, Not Harder. Way had a great package deal

with the pulley, belt, plugs, and tensioner stop and

provided a loaner pulley puller.

Standard

Disclaimer: ANY USE OF THIS INFORMATION

BY YOU IS AT YOUR OWN RISK.

Raising the motor

The motor has

to be jacked up a bit for access to the supercharger pulley and in order to

replace the upper motor mount. Start by jacking up the passenger side of the

car (or both sides) and supporting the car with jack stands- You may want to

loosen the lugs on the passenger side wheel before jacking since it will be

coming off.

The first

step is removing some nuts/bolts to allow the motor to be jacked up.

The

hose/wiring holder bolt should be removed using a 10mm socket/ratchet:

†

†

Next the upper

motor mount bolts need to be addressed- loosen but donít remove the driver side

motor mount bolt:

Remove the

passenger side ground strap nut/bolt (13mm wrench or socket) - be careful as

the bolt is captive underneath:

†

†

Remove the

passenger side motor mount nut:

Remove the

lower motor mount bolt closest to the oil pan:

†

†

After

removing the wheel, remove the passenger side wheel well cover, there are

several plastic Phillips head screws that can be helped out by inserting a

small flat blade screwdriver under the screw head in the opposing slots on the

base. There are also two screws, one on front and one behind that need to be

removed:

†

†

†

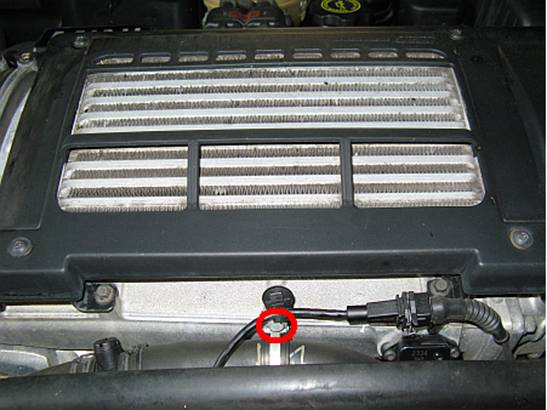

Place a

jack under the motor oil pan, I used a piece of wood to spread the load and

centered the jack where the oil pan drain plug is:

While jacking

the motor up, you want to listen and look for problems: wires or hoses getting

pinched or tight, interference of components, power steering pump/fan, ignition

coil wiring, etc. The motor just needs to

be high enough to remove the

Replacing the upper passenger side

motor mount

Since the

upper bolt has been removed to lift the motor, there are only a few more things

required to remove the old mount. The mount has a support that bolts to the

strut tower, this bolt should be removed.

Only one more bolt remaining: the bottom one. It

requires an external Torx, E12 socket to remove:

†

†

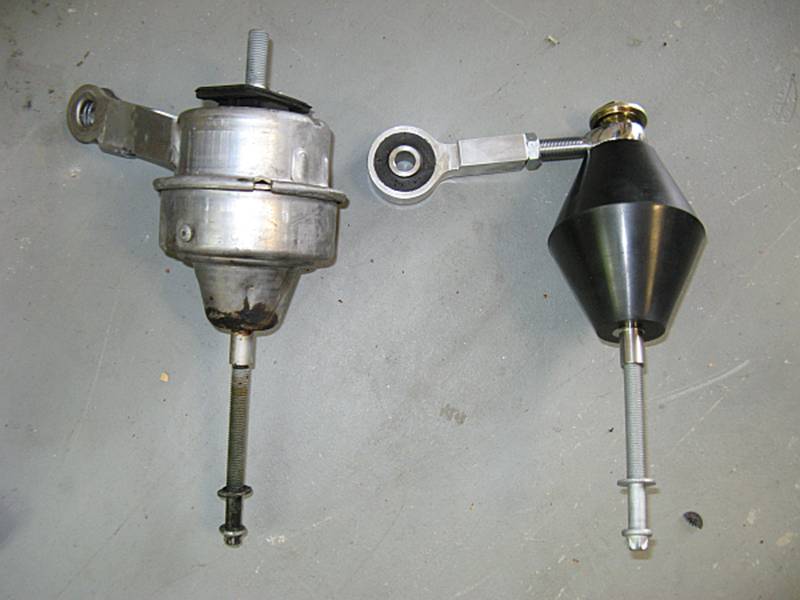

Comparing

the old and new mounts:

For

installation I will defer to the TSW

provided instructions which are located HERE, remember to install all bolts

removed and torque to spec.

Replacing the pulley:

Before

using the tensioner tool, there is a vacuum hose in

the way that needs to be removed- just press on either side and pull to

release:

†

†

The tensioner tool has two pins that go into the lower part of

the tensioner and the supercharger bolt is used as a

fulcrum point:

†

†

While the tensioner tool is used to compress the tensioner

spring, insert a small piece of wire or a hex key into the SECOND slot on the tensioner holder. The serpentine belt can be removed from the

SC pulley:

The OE

pulley is press fit on to the supercharger shaft and will have to be removed

using a pulley puller. The OE pulley has a plastic center piece pushed into the

threaded SC snout, it can be removed with a small flat

blade screwdriver:

†

†

The pulley

puller I am using is the CravenSpeed puller, it will allow the pulley to be removed without

removing the tensioner assembly. Since it uses the SC

snout as a point to push the pulley off, a bolt is used to protect the SC shaft

nose- some use the bolt that held the ground wire to the passenger side mount.

To reduce friction and help with smooth removal, apply some anti-seize to the

bolt head after the bolt is screwed into the snout:

†

†

Because of

the amount of force it will take to remove the pressure fit pulley, it was

suggested by both Way and CravenSpeed to LIBERALLY use anti-seize with the

puller:

The puller

body will slip over the pulley and mesh with the belt grooves on top. Once it

is in place the puller bolt can be installed. A wrench is used to hold the

puller body while another wrench is used to turn the bolt- this will pull the

pulley off the SC shaft. It may be easier to access the puller bolt by having a

friend push the motor back and/or hold the puller body wrench as the puller

bolt is tightened:

†

†

†

†

Clean all

of the anti-seize off the SC shaft nose before installing the new pulley.

Way

suggests using the CravenSpeed

pulley installation instructions found HERE to install the new pulley, they

also have a picture of the belt routing for installing the new belt. Remember

to reinstall the vaccum line after installing the

belt and using the tensioner tool to release the tensioner.

Installing Tensioner

Stop and Damper Bushings:

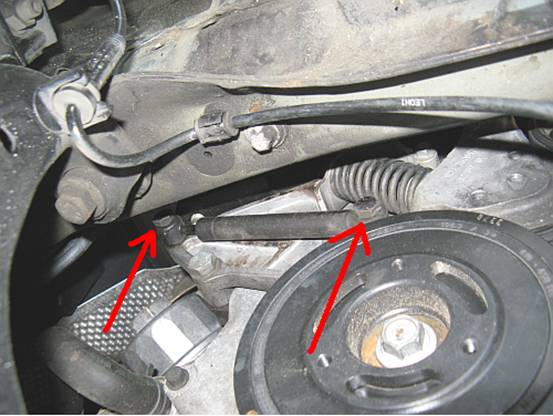

The tensioner stop prevents the tensioner

from slamming into the crank if/when the belt breaks. Since this was being

installed it was also a good time to upgrade the bushings to poly as another

preventative failure item. The tensioner damper is

held in place with two bolts, these will be removed so that the tensioner damper bushings can be installed (removal of

damper not necessary if only the stop is being installed, this can be done one

bolt at a time). If the motor had not been jacked up for other projects,

accessing the damper bolts would have been easily done from below after

removing the wheel well cover:

†

†

To remove

the old bushings the metal sleeve is pushed/pulled out and then the bushings

press out easily:

†

†

Bushings

are installed the same way they were removed- insert poly bushing and once

seated insert metal sleeve. The bushings come with lube that looks a lot like

the anti-seize I used on the pulley puller, I used it around the bushings

themselves and the metal sleeves inserted into them:

Now that

bushings are in, time to reinstall damper with tensioner

stop. Install one bolt at a time trying to keep stop end parallel with damper

while tightening:

After installing JCW cooler spark

plugs (aka NGK BKR7EQUP), enjoy your new found power

and peace of mind.

†

†