BMW

E90/91/92/93 M3: UUC EVO 3 Short Shifter Installation

The UUC

shifter comes packaged with all the pieces needed to install their Evo 3 short

shifter. Additional carrier lock pins (circled below) are included if the

installer desires to remove the carrier during installation, as suggested by

the UUC installation guide:

NOTE: The following is provided for information only and any use of

this information by you is at your own risk.

The car

needs to be placed on jack stands for access to the bottom of the shifter, the

easiest way for me to do this was to drive the car on ramps so that I could use

the big jack at the front jack point to lift the car and get jack stands under

the front jack pads (rubber hockey pucks used to pad stands). I use Rhino ramps

with “helper” ramps (2”x4”s with 45 degree cuts) to avoid contact with the

front bumper. I left the ramps under each wheel, never can be too safe when

working under a car:

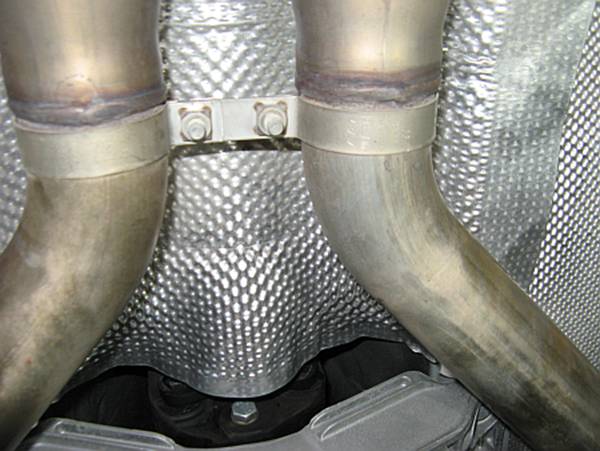

The UUC

installation instructions suggest removing the exhaust/lower cover plates/heat

shields to remove the shifter carrier. Since I was not installing the DSSR but

only the SSK, I only needed enough room to get to the clip holding the selector

rod to the shifter. In past installations I have been able to bend the heat shield

and then bend it back when finished and it has worked well without the added

labor. The heat shield I needed to work around is at the rear of the

transmission cross-member. I removed the sheet metal nut on the driver’s side

with a 10mm wrench and the bolt on the passenger side with a 13mm wrench to

allow a little movement while bending out of the way for access. Pulling down

the heat shield in the middle under the drive shaft allowed plenty of room for

access (and may even work for DSSR installation), I was able to get two hands

in to position the shifter/selector rod and remove/attach the retaining clip. [NOTE: The

heat shield can most likely be bent a few times and a few different ways (no

sharp angles when bent is best) before it starts to tear/break but it is a lot

like an aluminum can- bend it enough times and at sharp angles and it will

tear/break, this is the risk to using this method. I have done this a few times

and never had one tear/break but that is a decision you ultimately have to make

since you will be the one responsible for any resulting issues]:

The

shifter is held to the shift rod with a C-Clip, it can be removed by pressing

the base of the clip with your thumb or with the help of a screwdriver:

Back up top,

the first thing I did was remove the shift knob (pull up hard), the shift boot

(four clips, removed by tugging upward gently at clip areas), the foam insert

around the shifter, and the carpet around the shifter:

The rubber

boot can be carefully removed as well by pulling up in one spot and working

around the seal until separated. Front and back are the hardest since there is

more seal area there to pull up. Be careful not to rip the boot in the process.

If it is difficult to do from the top, you can always push it up and out from

below. Note the arrow on the boot points toward the front of the car and

remember this when reinstalling:

Note in

this picture of the bottom of the boot the area that goes around the shifter

carrier opening, this can be felt/positioned through the top part of the boot

during reinstallation and should fit securely around the recess in the shifter

carrier at the base:

The

shifter is also held to the carrier with a plastic collar, it needs to be

rotated clockwise to release from the carrier slots it locks into. This plastic

collar can be turned by inserting needle nose pliers or small standard

screwdrivers into the slots located around the perimeter of the collar. I was

able to get the collar turned easily with two small screwdrivers on opposing

sides- once the tabs highlighted are rotated clockwise about 90 degrees they

are free of the slots that retain the bushing and the shifter can be lifted out

of the carrier:

To install

the UUC carrier pivot height adapter, the white ring bushing is placed in the

shifter carrier with the cup towards the top. LocTite is applied to screw holes

on either side of the pivot height adapter and it is placed on top of the

bushing, it should seat around the lip of the bushing:

The pivot height adapter is installed using 6 small HEX

screws, it should sit flush with the bushing in the carrier base and the screw

holes should line up with the slots in the carrier. Screws are installed

loosely by hand and then tightened with supplied hex wrench alternating sides.

After getting one screw on each side started it was much easier to start the

other four using the one installed as a reference point. Be careful to get the

screws just hand tight, no need to crank on the hex wrench ![]() For me, installing the adapter this way was

easier/faster than dropping the exhaust/lower plates/heat shields as

recommended by the UUC instructions but if you have a lift at home the UUC

instructions may work better- the screws would definitely be easier to install

with the carrier removed.

For me, installing the adapter this way was

easier/faster than dropping the exhaust/lower plates/heat shields as

recommended by the UUC instructions but if you have a lift at home the UUC

instructions may work better- the screws would definitely be easier to install

with the carrier removed.

(HINT: I found that using my grinder to cut down the hex

wrench allowed for easier use):

Supplied grease is then applied to shift ball, order of

components for installation into carrier from shift ball up should be nylon

cup, spring, spring retainer, and snap ring:

To install shifter in carrier, snap ring pliers are used to

insert snap ring into adapter after shifter is placed in carrier. Now is also a

good time to make sure the height adjustment nut is tight, I found mine was not

and allowed the shift knob to turn although the height was stable. Also note

the slight bend above the pivot ball, the shifter should be installed with this

bend towards the rear of the car after the snap ring is installed:

Shifter is then connected

to selector rod by placing bearing liners into bearing on either side, sliding

selector rod pin through bearing liners, installing yellow plastic washer, and

finally installing the C-Clip. There was NO way the plastic washer was going to

work with the clip in my case (you can see in the pics that the locking clip

ridge was just flush with the bearing liner) so I left it out- the selector rod

is tight and the bearing liner is the piece that moves (there is no movement

between it and the locking clip) so I am not worried. Since my M3 has 20k miles

on it, the selector rod pin had just enough corrosion on the tip (where the

locking clip slides on) to prevent the bearing liners from going on. I used

some fine red Scotch Brite to polish the ends and some Mobil1 spray lube and

they slid right on. Make sure the clip snaps/locks over the selector rod pin,

the UUC provided clip is a slightly different design that allows the clip to

lock on the rod a little more securely:

Heat shield is bent back

to normal (I was careful when bending it back to make sure the heat shield did

not make contact with the driveshaft) and bolted back up, shifter rubber boot

(arrow on boot towards front of car), carpet, foam, shifter leather boot, and

knob are reinstalled. When reinstalling the rubber boot, the lower seal for the

smaller ring on the carrier around the shifter can be pressed on/around the

carrier opening by feel through the rubber boot as the larger lip is press fit

into the console body hole.

END RESULT: The UUC Evo3 is much more solid and positive feeling when

compared to the OE shifter and is a bit shorter as well. NO added vibration or

noise is perceived and at this point I have not noticed any drawbacks to

installing this, only benefits ;-)