This is an attempt to present a step by step installation

guide for the full GWR exhaust (headers, mid pipe and rear silencer). Most of

the information is available through GWR forums and miata.net postings, but I

have tried to present a more complete guide, after having completed the

install myself, following the guides / information floating around. Apologies

for the huge posting, and the large pictures.

First of all, let me start by sharing with you that I am not a professional mechanic, I know basic stuff and have some tools but

really never changed a header before in any car. Have striped a bolt or two

(not on the MX5), and that is all. Having said that, most people and Brian

say the install is doable by a good shade-tree mechanic, within 8 hours. I could

not do it within that time frame (more like 12-15 split across several days),

mostly because of things not going the way they should, and of some hidden

difficulties. I have also taken my time, did not want to rush things, and

also did some cleaning of the underside while everything was off the car.

The tools/items that you will need are:

1) Wobble Socket Extensions. These will come handy for reaching difficult

bolts on the header, alternator, outer header heat

shield.

2) Oxygen Sensor Socket. This looks like a 22mm deep socket, with a cut along

one of its sides. Some people do the install without it, but it is better to

have it. You may be able to borrow it from a friend. You should have it to

avoid damaging the first O2 sensor, which is by the way, mighty expensive to

replace! This sensor has a dish around its base, which makes it quite

difficult for an open end spanner to safely grip the sensor.

3) Offset ring spanners. Again may come handy for the header bolts. If not a

set, at least a 15mm one for these bolts.

4) Ring/open end combination spanners

5) Good set of ratchets. A small, and a medium length at least, and quality

sockets.

6) Deep socket set

7) Anti-seize compound. I used Molyslip Alumslip on all the exhaust bolts. A painter's flat paintbrush

No. 6 will be handy for application.

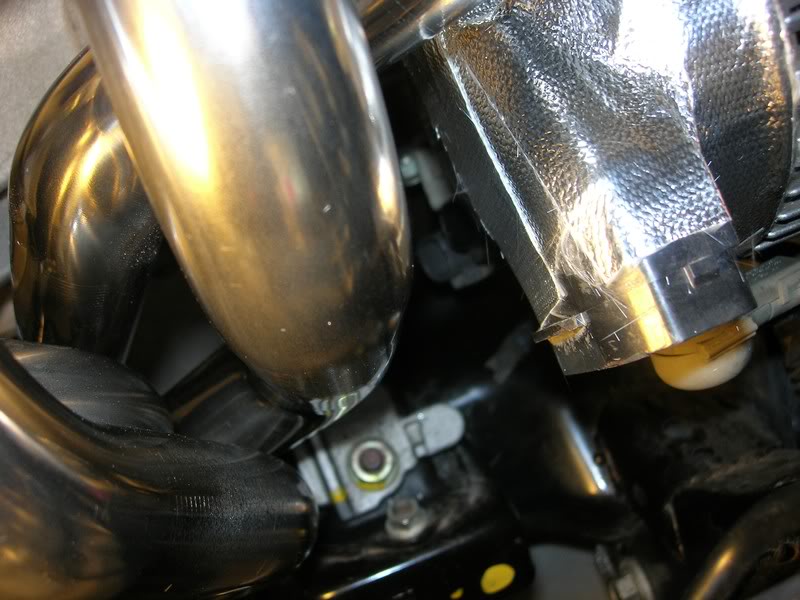

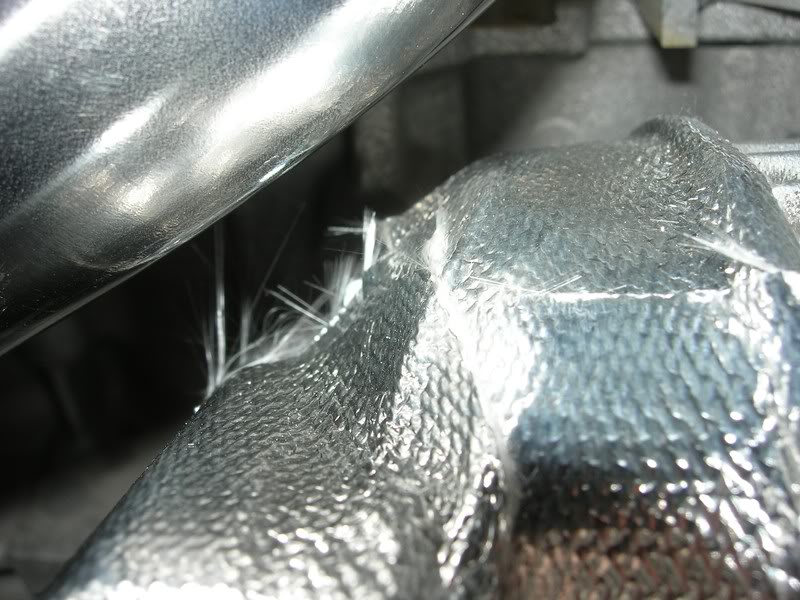

8) Some thermal tape and optional aluminum tape. I used the thermal tape for

covering the alternator back housing, the outer (brake lines) heat shield and

for protecting the O2 sensors wires. The latter is optional, and probably an

overkill, but it is better to be safe than sorry! Aluminum tape was used on

top of the thermal tape on the cables. This not only heat proofs them, but

also makes them stiff, so they can retain the shape you will give them.

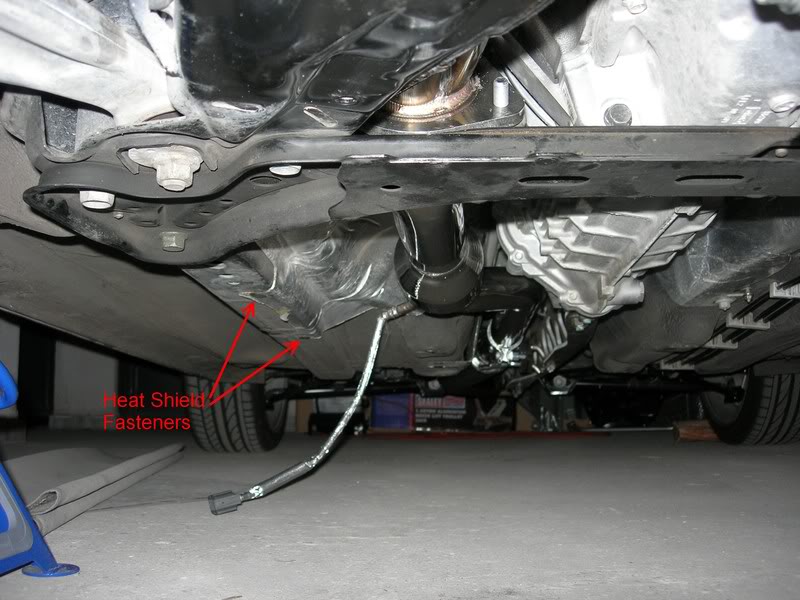

9) Bent needle nose pliers. These will come handy when removing the two

fasteners holding the catalyst heat protective material under the car to pass

over the cable of the second O2 sensor. Alternatively, if available, a y

shaped tool for removing trim fasteners. Unlike the plastic fasteners in the

fender wells and in the trunk, those two on the underside heat shield are

quite firm and require a tool. The heat shield itself is easily damaged, so

extra caution should be taken when removing them.

10) 2 high tensile bolts and washers (Optional). I used high tensile, grade

8.8 black bolts and heavy duty stainless washers (30mm outside diameter, 11mm

inside dia., 2mm thickness). These will be required for the connection of the

mid pipe to the header. Normally you can use the factory studs, but mine came

off with the nut stuck on them. If you have a vice grip, you may be able to

undo the nuts from the studs. Otherwise just buy the bolts and washers. Make

sure the bolts you buy are fine pitch (1.25mm)! Length should be 70-75mm,

10mm dia.

11) Torque wrenches. This may be optional, and totally up to you. Personally,

I like to know that any bolt that was touched, is

again fastened to the specified torque. I could not manage to use it on all

the header bolts, but it is a good tool to have to get a feel at least on how

much torque each bolt/nut requires. I used an expensive model, and a smaller

budget one.

12) Header gaskets (Optional). Normally you will not need to change them.

While trying to remove the old header from the car, I managed to place a

small dent on the bottom ring gasket though. I did not want to take any

chances so I bought a new one (Part number: L315-40-581). The cylinder head

side gasket was reused (only 23K Kms on that). Bare in mind that although in US the ring gasket is around

$25, here in Greece

the price was 62 Euro! Therefore, best to check with your local parts shop if

you are not in the States. To avoid buying the gasket altogether, REMOVE IT

BEFORE YOU START TO PULL THE FACTORY HEADER OFF THE CAR!

13) 2xBolts, 2xNuts, 4xWashers, 2xspring washers. All stainless. Length of

bolts should be 45mm min, diameter 10mm. These will only be required if you

only have metric spanners/sockets. The Q exhaust uses US size and

thread bolts and nuts, and although a 16mm will safely hold the bolt, the nut

is something between 17 and 18mm.

On to the install:

Start by unbolting the lugs on the front passenger side wheel. Do not remove

them just unbolt them. Raise the car and place on jack stands. Ideally you

can use 4 jack stands for maximum clearance when working under the car. I did

not have two sets, so just two were used on the front jacking points.

Hand-brake applied, car in gear, rear wheels choked.

SAFETY FIRST!!!!!!!

MAKE SURE THAT YOU DO NOT USE JUST JACKS TO RAISE AND KEEP THE CAR OFF THE GROUND !!! ALWAYS, ALWAYS USE JACK STANDS!!!! NEVER EVER

WORK UNDER OR AROUND A CAR SUPPORTED ONLY BY A JACK!

Remove the wheel and place aside. Working in the engine compartment, remove

the strut tower bar if you have one. Since a lot of fasteners will be

removed, it is a nice idea to have some ziploc

plastic bags to keep all the fasteners for each component removed, safe and

labeled.

Working on the underside of the car, remove the oil pan protector plate. It

is held in place by 5 bolts (12mm). Place your jack under the oil pan, and

raise it until you feel some weight resistance. You do not want to raise the car, the jack is there just as a precaution. Paranoid

maybe, but you can never be too safe! Alternatively, if you do not feel

comfortable with the oil pan, place the jack in the middle of the front cross

member (this is the front jacking point indicated in the WSM, under the

differential for the rear).

Again working under the car, remove the front member bracket, cross brace and

if equipped transmission tunnel heat shield/protector. If you have any other

added under braces, all these should also be removed. Working inside the

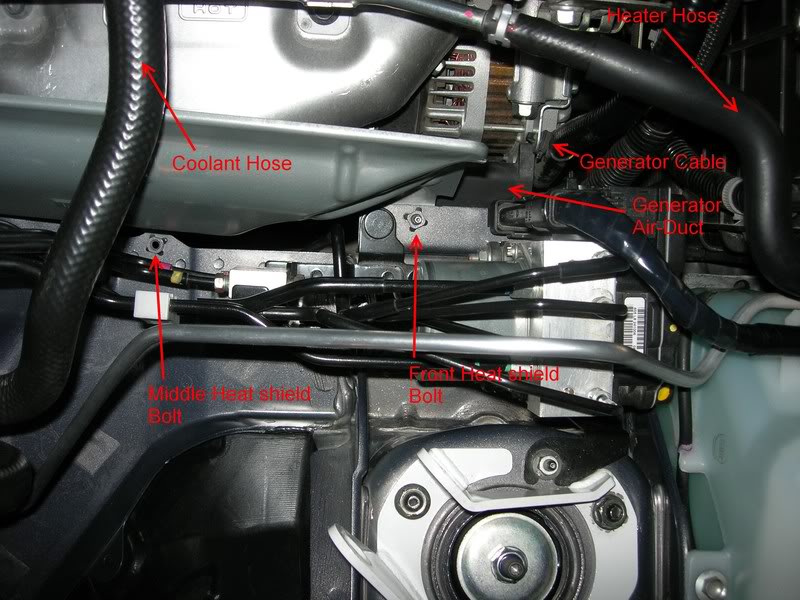

engine compartment, unhook the heater hose from the side of the battery cover

and remove the battery cover, J-hooks, battery and battery box. I did not

manage to remove the live battery cable from the box (it is held by some

really stubborn fasteners) so I just moved it forward. Remove the cable from

generator mount. This obstructs the generator's air duct bolt.

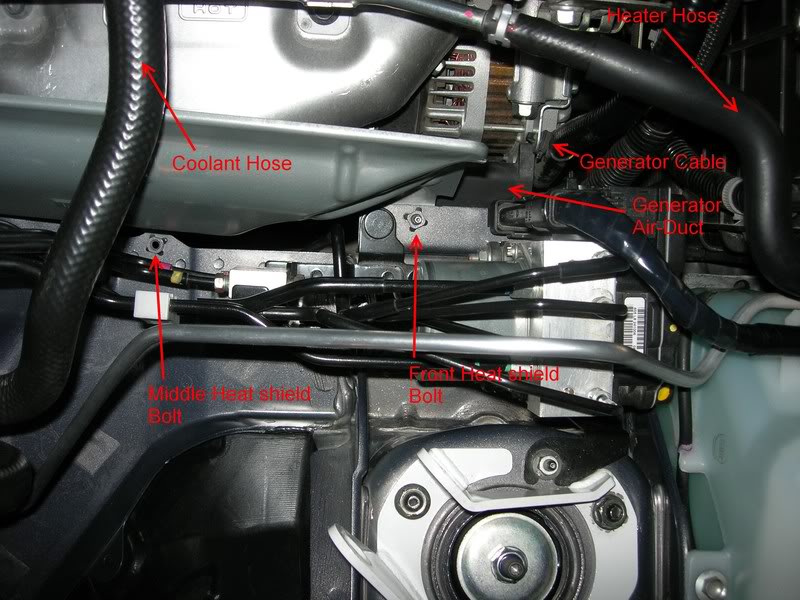

The following picture shows all the items I removed:

Below the battery is the outer (brake line) heat shield. In order to remove

that, you have to work under the car, near the passenger's lower wishbone.

There are two bolts that have to be removed, the middle and the front one.

Both are 10mm. Use extensions (I used 3) on a ratchet to reach the bolts from

under the car. The front one is hidden by the alternator's air duct. From the

top, undo the 10 mm bolt holding the duct and place it aside. You can now

remove the front outer heat shield bolt. Do not mix it with the ABS bolt (it

is a 12mm). Remove the rear nut and recover the heat shield.

Open the radiator cap to relieve any pressure, and close it again. We are

going to remove the coolant line above the header. Undo the clip holding the

heater hose in front of the car on the left of the coolant overfill tank. The

clip is reusable so do not loose/destroy it. Unbolt the line from the engine

and remove the hose from the coolant overfill tank by griping the hose clamp

with a pair of electricians pliers. Coolant may spill from here, so be

prepared to catch it with a bowl. Mine did not loose any. Use some masking

tape on the hose end to prevent dust entering. Do the same for the hose entry

on the coolant overfill tank.

We also need to move the heater hose out of the way. Again open the hose

clamp with pliers, ready to capture any spill, use masking tape on the hose,

and line ends. Secure the hose out of the way using cable ties. Undo the nut

holding the line on the engine and push it out of the way, together with the

coolant line we removed previously.

Next we are going to remove the header's heat shields. Use generous amount of

WD40 on all fasteners you can see. Spray also the studs at the mid pipe to

header connection and the bolts/nuts of the rear muffler to mid pipe.

The heat shields are 4 pieces. A top, middle and two on the lower part of the

header.

The top and middle are held in place by three bolts where they meet each

other. There is also a hidden clamp of sort, on the left side (as you look the

header from the passengers side), towards the firewall. Use a flat blade

screwdriver to push the clamp open (push towards the firewall).

Use a pair of thick gloves when handling the heat shields, they are razor

sharp! The bolts are really tight and here a quality set of sockets will pay

for itself. Be careful not to strip the bolts. Mine all came off with a bit

of effort. Remove the two black bolts of the top shield and then the 3 others

that hold the middle and top together. Remove the top shield and admire the

factory header! Use WD40 on all 7 header bolts. There is also another bolt

holding the middle heat shield, and the first O2 sensor cable support. Undo

the bolt and remove the support from the cable. The middle heat shield will

need to be bent to be removed from the car. Try to get it to clear the top of

the header, and then fold the left side edge of the shield towards its

centre. After some swearing the shield will be off the car :-)

– contd on next

post