Oil Cooler Upgrade Install Guide

CAUTION: Before beginning

please make sure that the engine is completely cold. Hot engine will have extremely

hot oil and components leading to the danger of being burned. Install at your

own risk. Not recommended for novice installers. I have updated this document that

Vince/VKM put together with some comments from my installation (in blue),

marked up existing pictures with red lines, and replaced some pics with my

pictures. My car is an E92 (Coupe) so this may have been why there were some

slight differences in my installation. If in doubt, compare this to the

original pdf document from VKM as it may be more applicable to your

installation. Bill

Tools needed for install:

13mm, 10mm, 8mm, and 6mm socket wrenches with

extension

T20 Torx driver

T20H Torx wrench

7/8” stubby wrench

Adjustable

Wrench (8” or 200mm length)

17/64” drill bit

Ruler

Dremel or similar cutting

tool

STEP 1: Remove air duct screws using a T20 Torx driver

(one on either side) and

disconnect air intake piping so that you can have room to access the oil cooler

thermostat housing.

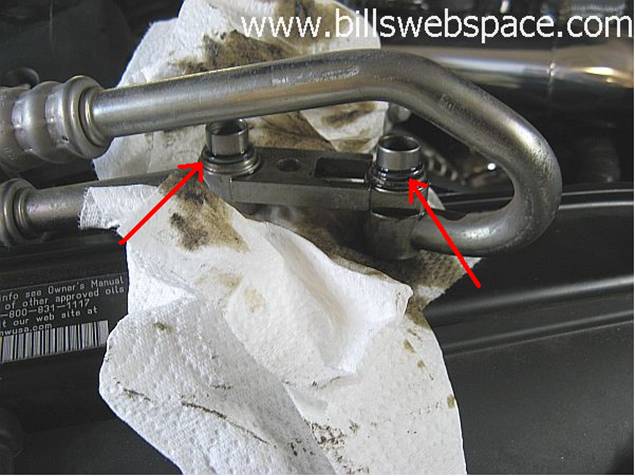

STEP 2: Using a 13mm socket wrench remove

the bolt that holds the oil cooler lines into the thermostat housing. Please

place a container under the thermostat as it contains oil. I used a small

¼” flex head ratchet with a regular 13mm socket, be careful that

no oil contaminates the serpentine belt located under and to the rear of the

oil filter housing.

STEP 3: Using a 13mm socket wrench with

extension, remove the screw on the other end of the oil lines. Note: Place a container under the oil fitting because the

lines will contain oil (a decent amount of oil,

more than enough to make a huge mess). Try to have the container lined up and

be fast, dumping oil takes no time at all

![]()

STEP 4: Locate the thermostat housing

adaptor provided in your V K Motorwerks oil cooler upgrade kit. It will look like

the part shown below:

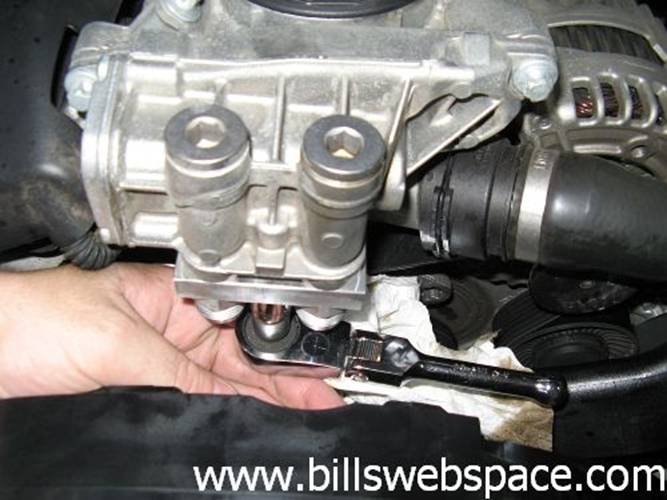

Step 5: Remove the two O-Ring seals from the OE

thermostat hoses and install them on the VK adapter. Using the bolt

that you previously removed from the thermostat, attach the V K Motorwerks

adaptor to the thermostat housing. You may use some grease to help

lubricate the adaptor. I found that the bolt area on the adapter is tight, a narrow wall

socket is required and my ¼” 13mm socket would not work. My

1/8” 13mm socket worked fine with an adapter (also helped as an

extension) using my ¼” ratchet.

Step 6: Lift your car using a jack and jack

stands and remove your

right front

wheel to access the

wheel liner bolts.

Step 7: With the 8mm wrench remove all the

bolts holding the wheel well cover in place. Only the lower left screw on the vent

retains the fender liner but its easy now to get the other three as well. Three

more screws in the top of the liner and three screws down the side are removed.

One plastic nut is removed using a 10mm socket or wrench. Five screws are

removed from underneath, some are hiding unless you are looking straight up at

them, specifically the one with the arrow in the picture below.

Caution: pull off the

wheel well liner SLOWLY…there is a Tire Pressure Monitoring (TPM) sensor

attached to the rear of the liner. Simply push the tabs together and the plug

should slide out. Do not use excessive force.

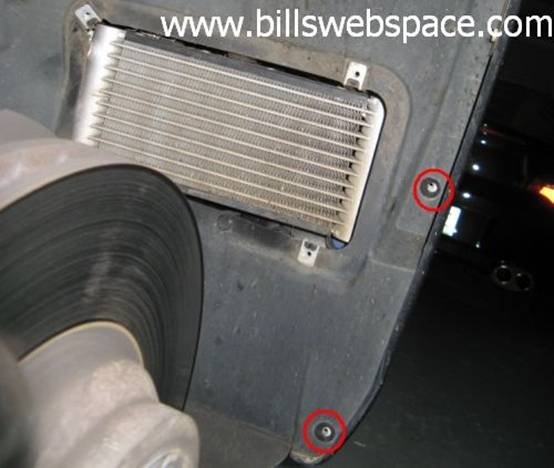

Step 8: Remove the screws and bolts on

both sides of the cooler. Please keep the cooler straight when you remove it

since it will be filled with oil. The three smaller screws (two on one side, one

on the other) require an 8mm socket, the single bracket screw requires a 10mm

socket, and the two nuts require a 13mm socket.

Step 9: Remove the air vent that is behind

the OEM oil cooler by loosening the tab inside the oil cooler air vent and

pulling up. The

rubber piece that holds the brake duct and the intercooler duct together in the

front can be pushed through and out from the front grill on the brake duct side

using a screwdriver so that they can be removed seperately.

Step 10: Now you must

remove the brake duct vent. You can do this by removing the 8mm bolt located on

the bottom left and side of the air vent. I found it easier to flex the duct and push towards

the front of the car to pull the front tabs out of the retaining holes, it allowed the duct to move a bit for easier access

to the single bolt at the front of the duct with a socket wrench or wrench.

Step11: Using a T20H Torx socket remove

the metal bracket attached to the top of the OEM oil cooler. The cheap bits I bought

broke on the first screw, so I used a pair of pliers on the outside perimeter

of the screw to get the second one out, a little slower but doable if you

don’t have one of these bits. After removing the screws, you should have

the bracket and two plastic washers.

Step 12: Reinstall the bracket,

you just removed to the top of the V K Motorwerks oil cooler with the two 6mm

hex head bolts that came in your kit. The supplied bolts do not work with the OE

plastic washers, I used a ¼” drill bit to

drill out the washers while clamped in a vise.

Step 13: Remove the rubber rings from the

OEM oil cooler and install on your new oil cooler. It is easier to install

these with the metal center section removed.

Step 14: Place your brake

duct vent as shown below:

Step 15: From the left edge, measure 1 inch

in and draw a line going perpendicular to the duct. From the same left edge, measure

4 inch in and draw a perpendicular line at this spot. It should look like this.

Due to

variances on cars, the 1” and 4” guidelines are close,

I found the 1” mark to be about 3/4” for me after adjusting and the

4” mark to be closer to

3.75”.

Step

16: Cut

out the area in between the lines. It is hard to see depth in the pictures

provided but I would start out at about 1/4" and cut more if you need to.

I also went ahead and cut ALL the plastic pieces at the same time.

Step 17: After completing step 16, your

brake duct vent should look like the picture shown below. Reinstall the vent by hooking the two rear

locating pins into the holes and then reinstalling the 8mm bolt at the front.

Step 18: By hand, attach the hose with two 90 degree fittings to the

inlet on the top of the V K Motorwerks oil cooler. Attach the straight fitting

to the bottom of the oil cooler. Do not tighten the hoses yet. After trying to do it a

few different ways I found it easier to install the bottom/straight fitting

hose after installing the intercooler; the top/angle fitting HAS to be

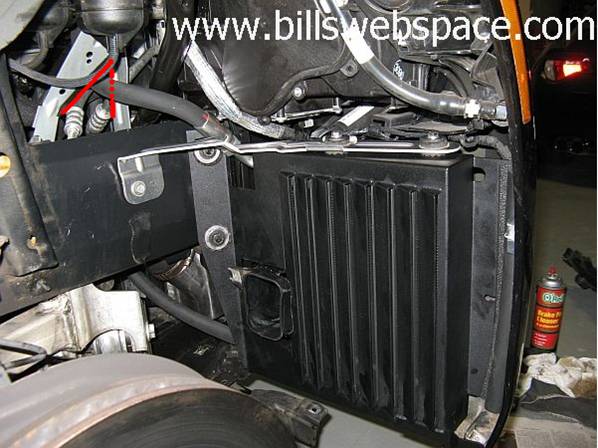

installed on the intercooler BEFORE the intercooler is installed.

Step 19: Mount the bracket and install the oil cooler to the car.

Once the oil cooler is mounted use a 7/8” stubby wrench to tighten both

of the hose fittings on the oil cooler. This is probably the toughest part of the install because of the tight

space. The

top oil cooler fitting is best accessed from the front using the cutout the

hose passes through, the bottom fitting can be accessed from below and behind-

it IS tight but doable.

Now, just for kicks,

compare your OEM intercooler to the new one you just installed.

![]()

Sears Item# 00944100000-Model#

44100

Sears Item# 00944100000-Model#

44100

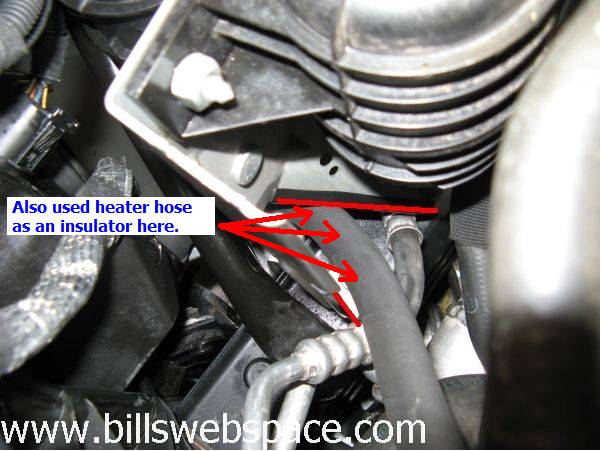

Step 20: Run the lines to the thermostat

adaptor and connect them. Make sure that they are not rubbing up against any

thing that can make them rip. The hose ends on the oil filter thermostat adapter can be

tightened using an adjustable wrench. Also make sure not to over-tighten the hoses. I used a combination of

soft plastic edging on metal edges and plastic conduit and cut heater hose to

make sure the oil cooler hoses would not be rubbing, make contact with, or get

cut on anything. Small adjustments to the angle of the fitting as they are

tightened can make a bit of difference too. I will probably check these hoses

periodically to make sure no rubbing issues exist.

Step 21: Now you will have to relocate your

TPM sensor. To do this you will have to push out the pins in your wheel well

liner. I

used the T20 Torx driver I already had out to push the pins out from the module

side and release the plastic rivets.

Step 22: Place the TPMS as shown in the

picture below and use a 17/64 drill bit to make holes to install the locking

tabs. The

1/4” drill bit I already had out worked fine for this, you will want to

position the TPMS module as close to the edge as possible to avoid interference

with the screw that will be close to the plugged in harness.

Step 23: Take the OEM oil cooler vent with

the side of the vent that faces into the wheel well count to the third vent fin

from the left. Measure up 5.25 inches from the bottom. Now mark this spot and

cut as shown in the pictures below.

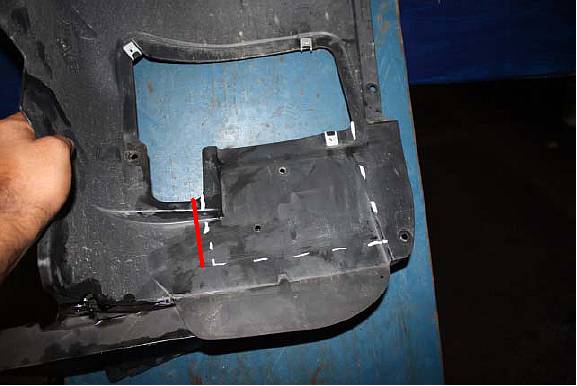

Step 24: Now you will need to cut the backing of that vent:

Mark the top of the vent as shown and cut.

My

cut deviated a little from the suggestion above, noted by the red line where

the suggested cut really did not work because the vent louvers are in the way.

Step 25: Now you have to cut the wheel well

liner. Mark and cut as shown below. Use the left and bolt screw as a reference

point to figure out how far to cut down. I had to move the left edge in the first pic

below out a ¼” to clear the cooler louver, again may vary due to

build variances. I found there were several ridges at the base of the fender

liner that caused clearance issues so I notched them to make them a little more

flat (picture shows what they looked like BEFORE fender liner was cut).

Step 26: Now install the

wheel liner and vent and you should end up with this:

Step 27: Put on the wheel and air intake

piece that you took out. Check your oil level, add if needed. My car was showing about

a ¼ quart low after installation.

Step 28: Enjoy your car!