SCOPE:

This report presents the

results of an ISO 5011 test of several air filters designed for the GM Duramax

Diesel. The test was independently performed under controlled conditions using

a $285,000 machine at Testand Corp of Rhode Island (manufacturer of the

machine). Arlen Spicer, a GM Duramax Diesel owner/enthusiast organized the

test. Ken an employee of Testand offered to perform the tests at no charge.

(These tests typically cost approx $1700.00 per filter). Ken, also a Diesel enthusiast and owner of a

Ford Power Stroke Diesel, shared Arlen s interest in performing an accurate

unbiased test of different types and brands of diesel engine air filters. The

filters used in the test were purchased retail and donated by Arlen and other

individual Duramax Diesel owners. The detailed reports from the test have been

compiled and are presented in the following pages. The final pages of this

report present the behind the test.

ISO 5011 Test:

The ISO 5011 Standard

(formerly SAE J726) defines a precise filter test using precision measurements

under controlled conditions. Temperature & humidity of the test dust and

air used in the test are strictly monitored and controlled. As Arlen learned in

attempting his own tests, there are many variables that can adversely affect

filter test results. A small

temperature change or a small change in humidity can cause the mass of a paper

filter to change by several grams. To obtain an accurate measure of filter

efficiency, it s critical to know the EXACT amount of test dust being fed into

the filter during the test. By following the ISO 5011 standard, a filter tested

in Germany can be compared directly compared to another filter tested 5 years

later in Rhode Island. The ISO 5011 filter test data for each filter is

contained in two test reports; Capacity-Efficiency and Flow Restriction.

Capacity and Efficiency:

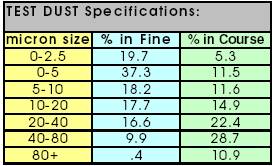

The Capacity and Efficiency

test report presents the test results of feeding an initially clean filter with

PTI Course Test Dust (dirt) at a constant rate and airflow. The course

test dust has a specific distribution of particle sizes ranging from less than

2.5 microns to greater than 80 microns (see table below). Every filter is

initially tested at 350 CFM and the Initial Restriction or differential

pressure across the filter is recorded in IN-H20 (Inches of Water).

The filter is then tested by feeding test dust at a nominal rate of 9.8 grams

per minute with a constant airflow of 350 CFM. The test is continued until the

flow restriction exceeds the Initial Restriction + 10 IN-H20.

At this point the test is terminated and the amount dust passed through the

filter - Accumulative Gain - is measured. Dirt passing through the

filter is captured in the Test Station s Post Filter. The exact amount

of dirt passed is determined by measuring the before and after weight of the Post

Filter. Similarly, the amount of dirt retained by the Filter under test - Accumulative

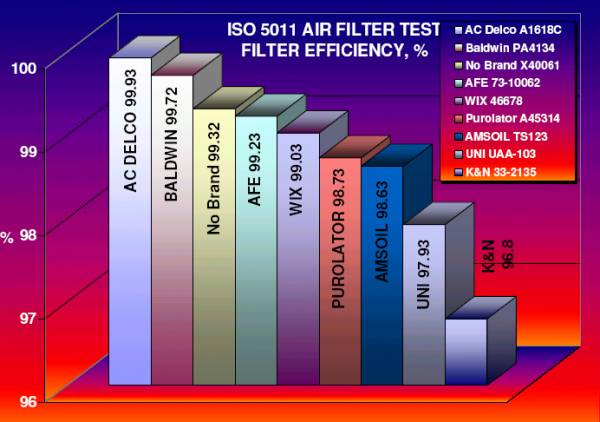

Capacity is measured by taking the difference between the before and

after weights of the Filter. From these results the overall % Efficiency

of the filter is calculated. This test

also indicates how long a Filter will last before replacement is required (or

cleaning for reusable filters).

Flow Restriction:

This report presents flow

restriction of a clean filter resulting from an increasing airflow. The

differential pressure restriction across the filter is reported in inches of

water (IN H2O) versus Air Flow in cubic feet per minute CFM.

Data from these reports has

been compiled and presented in the following bar graphs, Plots and data tables.

Filter Efficiency:

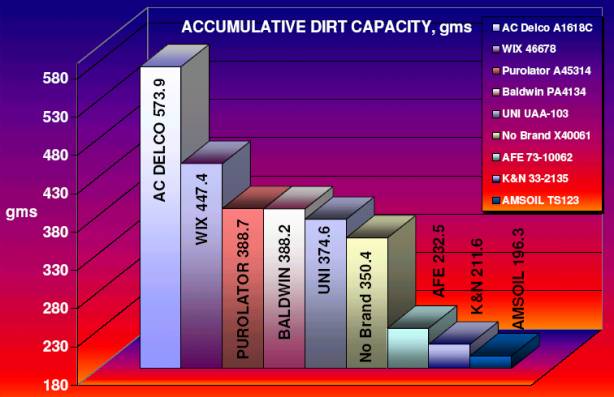

Accumulative Capacity:

Accumulative Capacity is a

measure of dirt holding/loading capacity before reaching the maximum restriction

limit - Initial Restriction + 10 IN-H20.

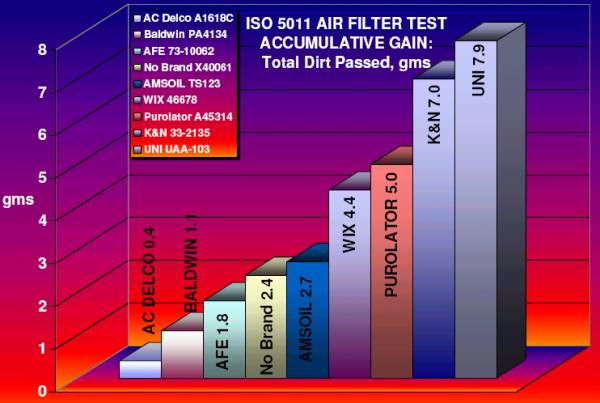

Accumulative Gain:

"Accumulative

Gain" is the total amount of dirt that passed through the filter during

the test.

(Note: The Purolator was reported to have a seal malfunction during the test and passed more dirt than it would have with a good seal.)

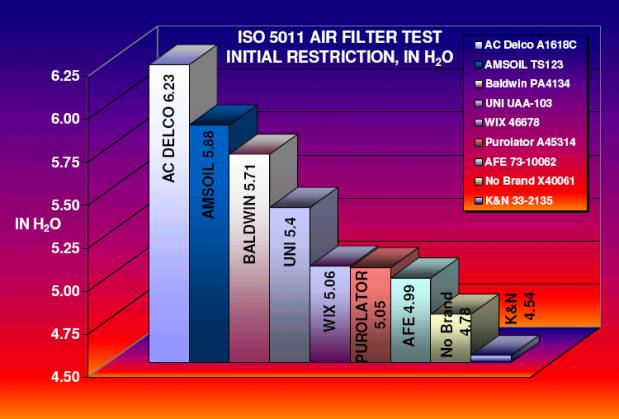

Initial Restriction:

Initial Restriction is the

Filter under test s resistance to flow at 350 CFM.

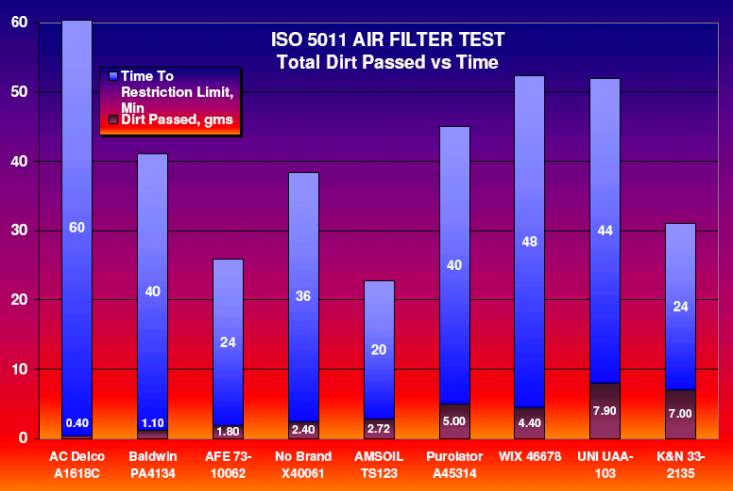

Dirt Passed Versus Total Test Time

This graph shows each the

duration of each filter s test versus dirt passed (Accumulative Gain).

(Note:

The Purolator was reported to have a seal malfunction during the test and

passed more dirt than it would have with a good seal.)

In the chart above it s

important to note the different test durations for each filter. The AC Delco

filter test ran for 60 minutes before exceeding the restriction limit while the

AMSOIL and K&N tests each ran for 20 and 24 minutes respectively before

reaching max restriction. In 60 minutes the AC Filter accumulated 574gms of

dirt and passed only 0.4gms. After only 24 minutes the K&N had accumulated

221gms of dirt but passed 7.0gms. Compared to the AC, the K&N plugged up nearly 3 times faster, passed

18 times more dirt and captured 37% less dirt. See the data tables for a

complete summary of these comparisons.

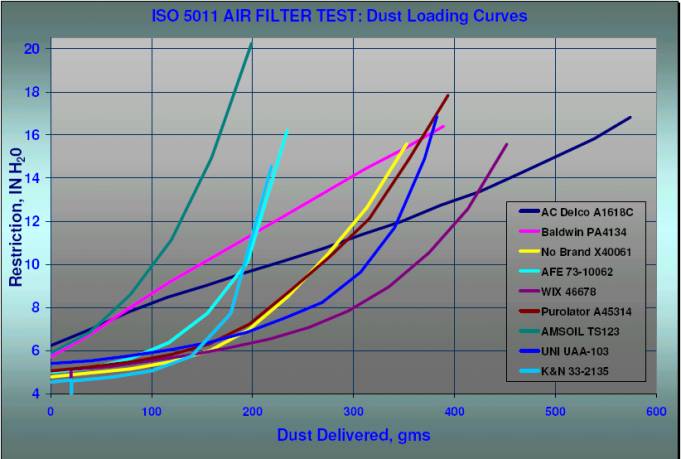

Dust Loading:

The dust loading curves show

graphically how each filter responded to a constant 9.8 gms/min dust flow

before reaching the maximum restriction limit.

It s interesting to note the

shape of these Dust Loading Curves. The AC and Baldwin filters each had near

linear responses until reaching maximum restriction. Restriction for these

filters increased at a constant rate versus the 9.8 gms/min dust feed rate. The

other filters, most notably the oiled reusable types, had an exponential

loading response before reaching maximum restriction. These filters had a lower

initial restriction, but they became exponentially more restrictive under a

constant flow of dirt. Also notice the length of the curves as it shows the

relative test time for each filter (time to max restriction).

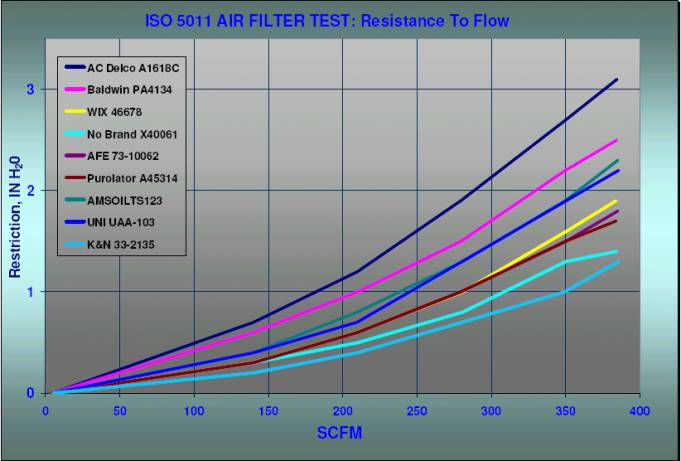

Restriction to Flow:

The Restriction to Flow

curves graphically show how each clean filter responded to a steadily

increasing flow of air up to 350 CFM.

The Flow Restriction

response curves for each filter have the same basic shape. However, note how

the AC Filter, which passed the smallest amount of dirt and had the highest

dirt capacity and efficiency, also had the highest relative restriction to

flow. The less efficient filters correspondingly had less restriction to flow.

This illustrates the apparent trade-offs between optimizing a filter for dirt

capturing ability and maximum airflow.

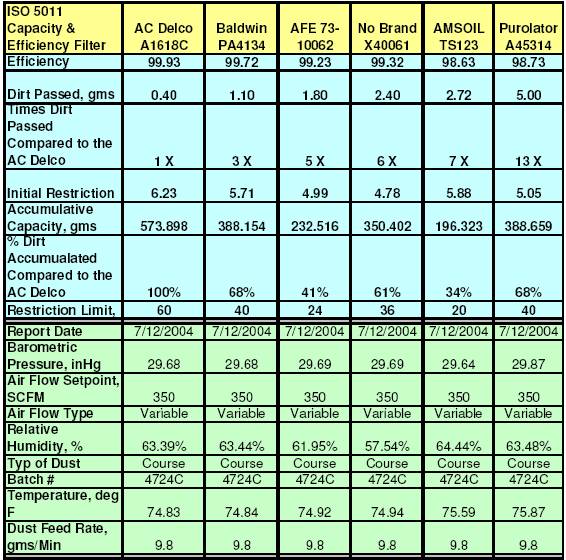

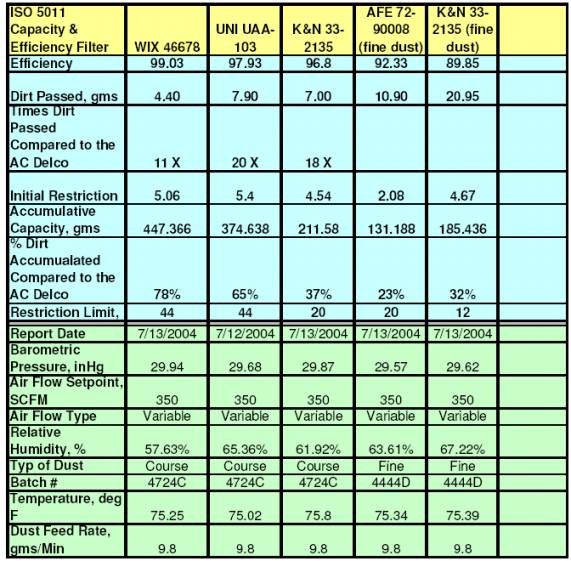

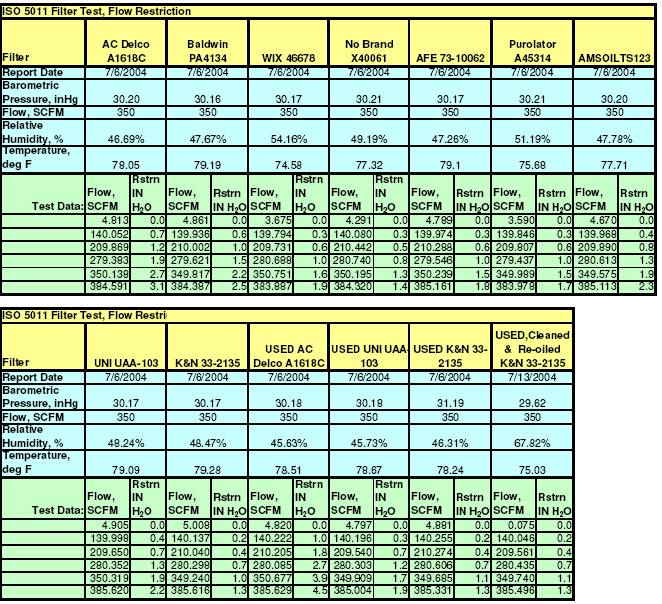

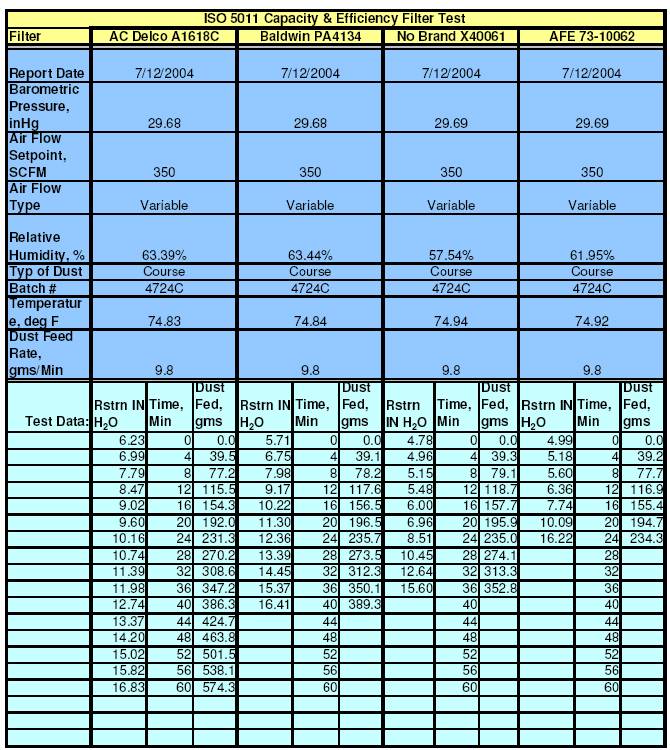

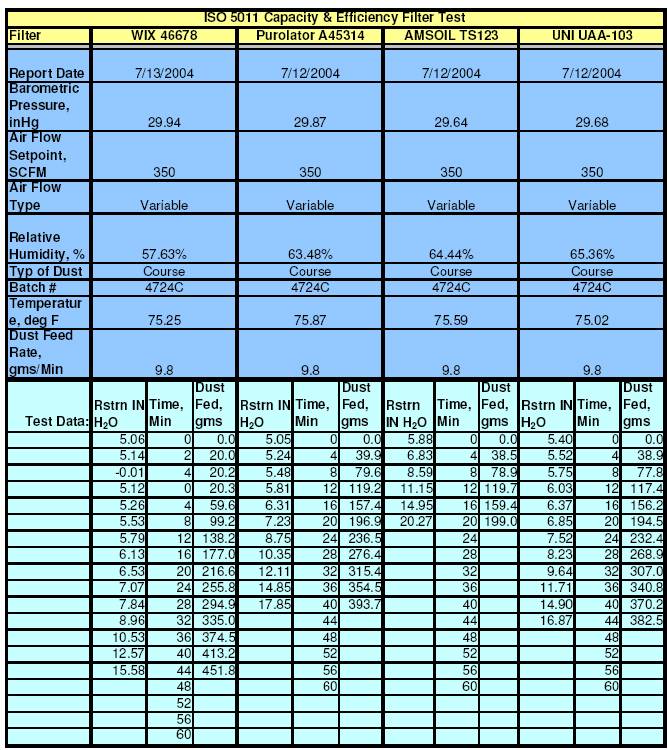

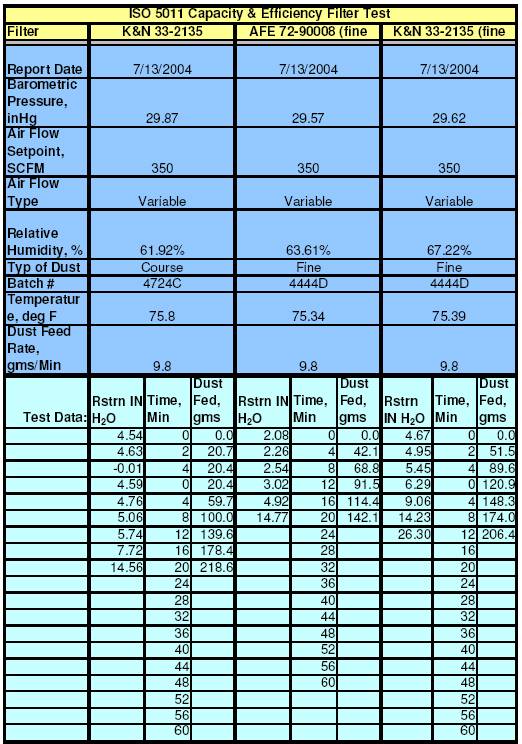

Test Data Tables:

Test Data Tables:

Test Data Tables:

Test Data Tables:

Test Data Tables:

Test Data Tables:

To be consistent with common industry practice all filters

were tested using PTI Course Test Dust. Course dust is more commonly used since

it will produce higher % efficiency numbers.

The Story behind the

test:

First of all, many thanks to

Arlen Spicer and Ken at Testand for organizing and facilitating the test. Arlen

is a professional Firefighter who also operates a small tree service on the

side. The tree service is the reason he owns a diesel truck. This study was the

result of nearly a year of work by Arlen to get accurate independent data on

air filters for the GM Duramax Diesel. Arlen originally set out to build his

own Filter Test Stand so that he could perform accurate, repeatable and

independent measurements on the various filters available for the Duramax.

Arlen questioned the claims made by aftermarket filter manufacturers that their

filters were superior to the conventional OEM style paper filters. After

spending many months, hours and a considerable amount of his own money, he

learned first hand how difficult it was to perform an accurate air filter test.

He found it was difficult to maintain all the necessary controls to insure an

accurate measurement. It was at this juncture that Arlen received a call from

Ken at Testand offering to perform the ISO 5011 test free of charge. Ken found

Arlen s idea for an independent comparison study very interesting and offered

to do the ISO 5011 testing using one of Testand s industrial Filter Test

Machines. Arlen posted the news on the Internet and immediately offers from

other Duramax owners to purchase and send filters for the test started rolling

in. Some purchased and donated filters and others made contributions to cover

the expenses and the cost of shipping the filters to Teststand. It was truly a

team effort. The end result is the top quality data presented in this

report. The following is a quote from

Arlen.

(Arlen) SPICER wrote,

Now that I am not doing

the tests and my objectivity is not necessary, let me explain my motivation.

The reason I started this crusade was that I was seeing people spend a lot of

money on aftermarket filters based on the word of a salesperson or based on the

misleading, incomplete or outright deceiving information printed on boxes and

in sales literature. Gentlemen and Ladies, Marketing and the lure of profit is

VERY POWERFUL! It is amazing how many people believe that better airflow = more

power! Unless you have modifications out the wazoo, a more porous filter will

just dirty your oil! Some will say " I have used aftermarket brand X for

XXX # years with no problems. The PROBLEM is you spent a chunk of ching on a

product that not only DID NOT increase your horsepower, but also let in a lot

of dirt while doing it! Now how much is a lot? ANY MORE THAN NECESSARY is TOO

MUCH!

Others are persuaded by the claims of aftermarket manufacturers that their

filters filter dirt "better than any other filter on the market."

Sounds very enticing. To small timers like you and me, spending $1500 to test a

filter sounds like a lot. But if you were a filter manufacturer and you

believed your filter could filter dirt better than any other media on the

market, wouldn't you want to prove it? Guess what. Test your filter vs. the OE

paper. It will cost you $3000 and for that price you will have the data that

you can use in your advertisements. Your investment will be returned a thousand

fold! EASIER than shooting fish in a barrel! So why don't these manufacturers

do this? Hmmm? Probably not because they would feel guilty about taking more

market share.

Now I am not saying that

ALL aftermarket filters are useless. A paper filter does not do well if

directly wetted or muddy. It may collapse. This is why many off-road filters

are foam. It is a compromise between filtering efficiency and protection from a

collapsed filter. Now how many of our trucks collapse their filters from mud

and water? However, if a filter is using "better airflow" as their

marketing tool, remember this....Does it flow better? At very high airflow

volumes, probably. BUT, Our trucks CAN'T flow that much air unless

super-modified, so what is the point? The stock filter will flow MORE THAN

ENOUGH AIR to give you ALL THE HORSEPOWER the engine has to give. And this

remains true until the filter is dirty enough to trip the air filter life

indicator. At that point performance will decline somewhat. Replace the filter

and get on with it.

Hopefully the results of this test will do 2 things. Shed some light on the

misleading marketing claims of some aftermarket manufacturers and/or give us

new insight on products already on the market that are superior to our OE

filter. I stand for truth and will eat my words publicly if my statements prove

wrong. I appreciate all of the help and support that you members have offered

in this project. It would simply be impossible without your help. A huge thanks

to Ken at Testand for his willingness to take on this project. I would be

spinning my wheels from here to eternity without his help SPICER

Our thanks to Arlen and Ken

for making the test happen and providing the valuable test results for the

benefit of all.

Sept 2004